SEOS®

Vorteile

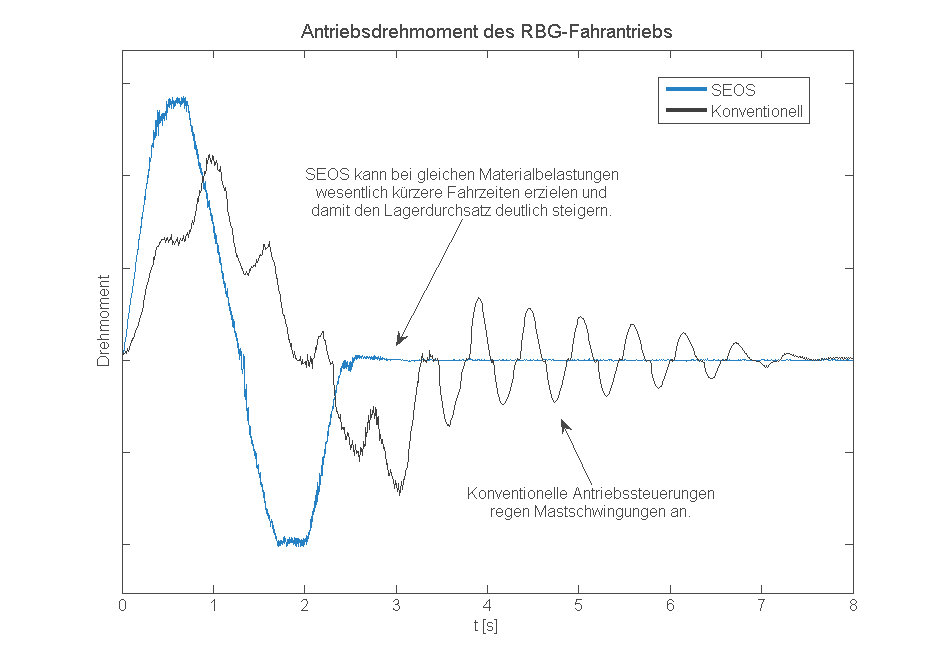

Die optimale Steuerung und Regelung mit SEOS® eliminiert Mastschwingungen und damit Wartezeiten bei der Zielpositionierung. Auch die Materialbelastung wird damit so stark gesenkt, dass die Beschleunigung in bestehenden Anlagen um bis zu 115% gesteigert wurde. Damit verkürzte sich die Dauer des Fahrvorgangs (Spielzeit) deutlich und der Lagerdurchsatz wurde um etwa 40% erhöht.

Mastschwingungen erhöhen das Risiko einer mechanischen Überbeanspruchung, die zu Rissen führen kann. Durch die Kombination der patentierten Steuerung und Anti-Schwingungsregelung in SEOS® treten keine Schwingungen am Regalbediengerät auf. Dadurch verläuft die Fahrt ruhig und kontrolliert, wodurch die Materialbelastung verringert und das Regalbediengerät geschont wird. Damit erhöht sich die Sicherheit im Lager

Durch Vermeidung von Schwingungen und durch den ruhigen und kontrollierten Betrieb des Regalbediengeräts werden Leistungsspitzen reduziert und damit der Spitzenverbrauch gesenkt. Zusätzlich kann durch die Verkürzung der Fahrzeiten der Energieverbrauch weiter verringert werden. Bei bestehenden Anlagen wurde der Energieverbrauch um ¼ gesenkt. Darüber hinaus ermöglicht SEOS® durch geringere Materialbelastung eine Leichtbauweise von RBGs, was sich ebenfalls positiv auf den Energieverbrauch auswirkt.

SEOS® berechnet die mechanischen Belastungen für jede einzelne Fahrt im Voraus, sodass Grenzwerte immer zuverlässig eingehalten werden. Durch intelligentes Anfahren und Bremsen werden Mastschwingungen vermieden, was bei bestehenden Anlagen zu 35% weniger Maximalbelastung führte. Mechanische Komponenten werden so geschont, die Abnutzung reduziert und die Lebensdauer technischer Bauteile verlängert.

Die Mastschwingungen eines Regalbediengeräts sind von einer Vielzahl an Parametern abhängig, wie z.B. Fahrweite, Verschliffzeit oder LAM-Höhe. Um diese Schwingungen minimal zu halten, muss der Inbetriebnehmer die Regelparameter bei konventionellen Antriebssteuerungen häufig durch aufwändiges Ausprobieren ermitteln. SEOS® kann durch die integrierte Modellierung und Optimierung geeignete Steuer- und Regelparameter automatisch so berechnen, dass Schwingungen nicht auftreten. Dadurch wird die Inbetriebnahme erleichtert sowie Zeit und Kosten eingespart.

Je höher Regalbediengeräte gebaut werden, umso schwingungsanfälliger sind sie. SEOS® reduziert die Schwingungen auf ein Minimum, sodass Bauhöhen um etwa 30% gesteigert werden können. Dies ist ohne zusätzliche Konstruktionsänderungen am Mast möglich. Dadurch kann mit bestehenden Konstruktionen eine höhere Marktabdeckung erreicht und unterschiedlichste Kundenanforderungen bedient werden, ohne dass Entwicklungskosten investiert werden müssen.

Zudem ermöglicht die schwingungsfreie Antriebssteuerung trotz großer Bauhöhen eine Leichtbauweise, die vor allem für Hochregallager attraktiv ist.

Videos

Funktionsweise

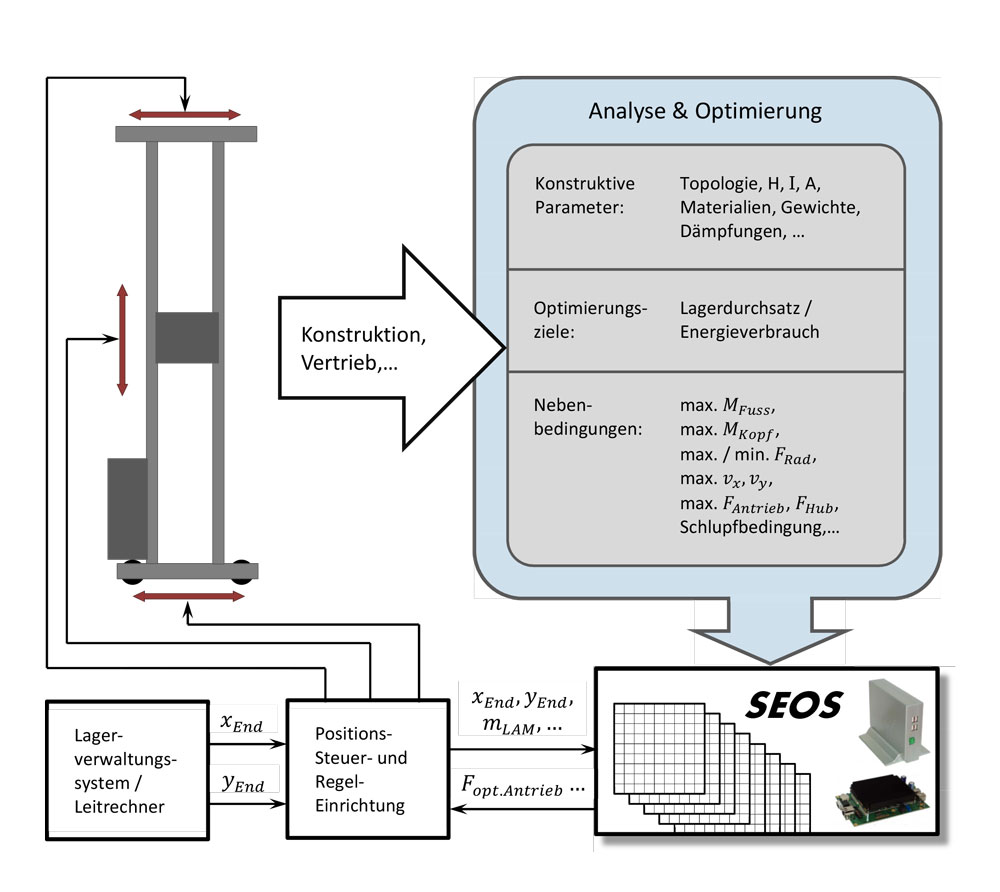

Sicherheit, Lagerdurchsatz und Energieeffizienz sind zentrale Anforderungen an automatisierte Regalbediengeräte. Durch einfache Integration der SEOS®-Technologie können diese Aspekte weiter verbessert werden. Die neu entwickelte Software kann die Bewegung des Regalbediengeräts genau vorausberechnen. Damit wird der Antriebsmotor so gesteuert, dass Schwingungen gar nicht erst entstehen. Durch optimale Fahrplanung und aktive Schwingungsreduktion lassen sich so deutliche Verbesserungen gegenüber konventionellen Systemen erzielen. Zudem ist die SEOS-Software mit allen gängigen Hardwareanbietern kompatibel und kann ohne großen Arbeitsaufwand in bestehende Anlagen integriert werden.

Details

Konventionelle Steuerungen regen Mastschwingungen an und branchenübliche Regelungen können diese Schwingungen nicht schnell genug eliminieren. Bisherige Lösungsansätze wie etwa Antipendelantriebe oder Schleichfahrten sind entweder teuer oder langsam.

SEOS® ist die erste Technologie, die allen intralogistischen Anforderungen gerecht wird. Deren Grundlage ist ein Modell des Regalbediengeräts, mit dem sich die Fahrt exakt vorausberechnen lässt. Vorgaben wie etwa die Grenzen der Materialbelastung können dabei individuell festgelegt werden.

Damit lässt sich ein Fahrverlauf vorhersagen, der keine Schwingungen anregt und dabei sämtliche Einschränkungen und Anforderungen berücksichtigt. Somit können in erster Linie Sicherheit, Lagerdurchsatz und Energieeffizienz erhöht werden, aber auch der Materialverschleiß wird durch die geringere Belastung minimiert.

Einfache Integration

Die SEOS®-Software kann ohne großen Aufwand sowohl in neue Anlagen integriert werden, als auch bereits bestehende Regalbediengeräte erweitern und verbessern. Vor der Installation werden die Vorgaben und Ziele gemeinsam mit dem Kunden definiert. Dabei werden bei einem ersten Treffen bereits installierte Hardware und auch verfügbare Schnittstellen abgesprochen. Vorhandene Motoren und Umrichter können unverändert übernommen werden. Ein großer Vorteil der Software ist, dass sie mit allen branchenüblichen Hardwareanbietern kompatibel ist. Sämtliche bereits bestehenden Sicherheitseinrichtungen werden nicht beeinflusst. Sollte zudem bereits eine SPS vorhanden sein, so ist für den Betrieb der SEOS-Software keine zusätzliche Hardware erforderlich.

Sind diese Fragen geklärt, kann SEOS® im nächsten Schritt bereits integriert werden. Alle erforderlichen Maßnahmen werden von Berger Engineering vor Ort durchgeführt. Wurde eine neue SPS benötigt, wird diese an den Umrichter angeschlossen und das Bussystem in Betrieb genommen. SEOS stellt sich automatisch auf das angeschlossene Regalbediengerät ein, berechnet die optimalen Fahrkurven und ist dann betriebsbereit.

Downloads

Hier finden Sie verschiedene Downloads zum Thema SEOS®:

Broschüre anfordern

Für mehr Informationen zu diesem Produkt können Sie uns gerne persönlich kontaktieren, oder unsere Produktbroschüre anfordern.