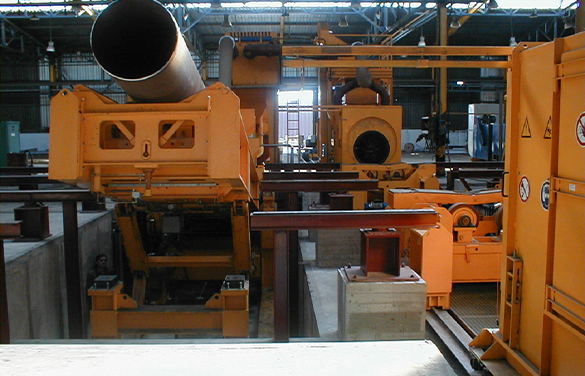

Pipe coating plants from Berger Engineering

We supply external and internal pipe coating systems.

Before the pipes can be coated, the pipes must be cleaned. This is done using a sandblasting system and / or a glass bead system, depending on the quality of the pipes and the coatings.

After cleaning, the coating is carried out using lance blast machines.

Depending on the diameter of the pipes (from Ø500 mm to Ø2800 mm) and the length of the pipes, the coating process can take 25 seconds to 135 seconds.

THE ENTIRE CONSTRUCTION OF THE COATING SYSTEM CONSISTS OF:

- Pipe cleaning system

- Sandblasting machine

- Emptying station

- Lifting and lowering platforms and devices

- Transport device

- Coating plant

- Drying station

FACTS:

- Pipe diameter 500 – 2800 mm

- Material of the pipes: steel, stainless steel, concrete, etc.

- Length: 4 m to 16 m

- Temperature: +20°C to +250°C (outer coating)

- Temperature: +20°C to +110°C (inner coating)

COATING TYPES:

- Polyurea coating

- Epoxy resin

- Zinc coating

- Interior cementation

- Bitumen coating

REQUEST A BROCHURE

For more information about this product, please contact us personally or request our product brochure.