After our SEOS® software went into operation in the new warehouse of Bell Schweiz AG in spring 2020, the retrofit of the existing warehouse with new stacker cranes from Stöcklin has now been completed. We would like to thank the experts of our customer Stöcklin Logistik AG for the excellent cooperation.

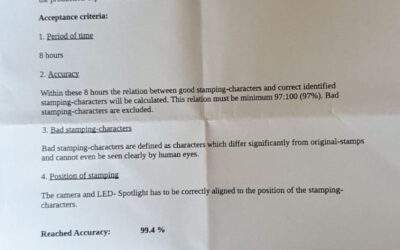

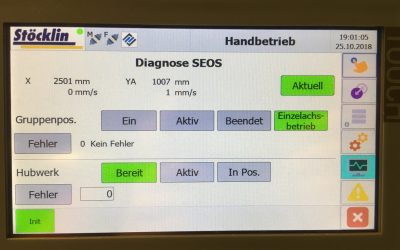

In the existing warehouse, storage and retrieval machines from another manufacturer were originally installed, which, due to their height of 20m, were equipped with anti-sway drives to prevent mast vibrations. As before in the new warehouse, the four new devices in the existing warehouse were all equipped with the innovative SEOS software solution. This is why anti-sway drives are no longer required with the new devices. Saving the anti-sway drives enables faster commissioning, easier maintenance and, of course, significantly lower acquisition costs as well as permanently lower maintenance costs. We therefore assume that in the future more and more old systems will be retrofitted with which these savings can be achieved.