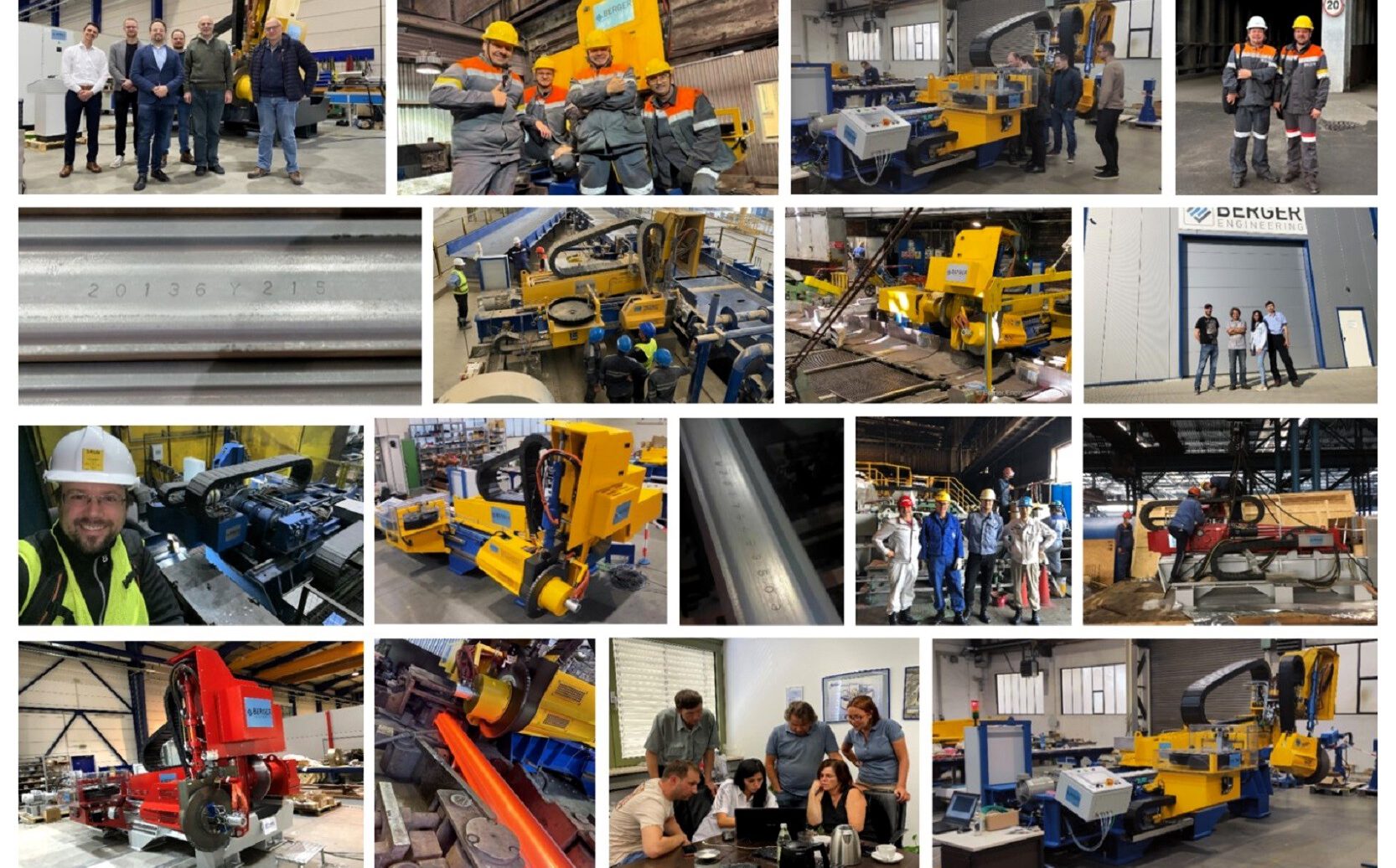

In 2024, we celebrated a remarkable anniversary: 30 years of rail stamping machines STEMA®. Since the launch of our first machine three decades ago, our company has continuously evolved and made a significant contribution to the global railway industry.

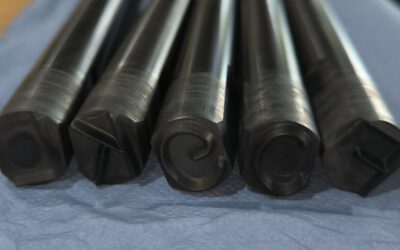

Today, our rail stamping machines are used to mark more than 96% of the railway rails produced worldwide. This not only highlights the high quality and precision of our technology but also reflects the trust our customers place in us.

In light of new developments, we have further optimized our machines. With innovative improvements in precision, energy efficiency, and digital control, our rail marking machines are well equipped to meet the challenges of modern rail production.

We thank our customers, partners, and employees for their continued trust and collaboration.