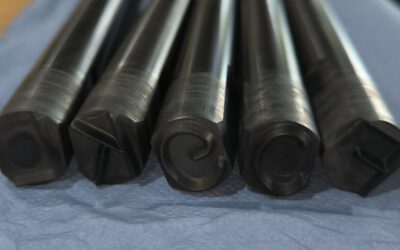

Under the technical leadership of Dr.-Ing. Benjamin Berger, the first rail marking machine in Egypt was successfully commissioned.

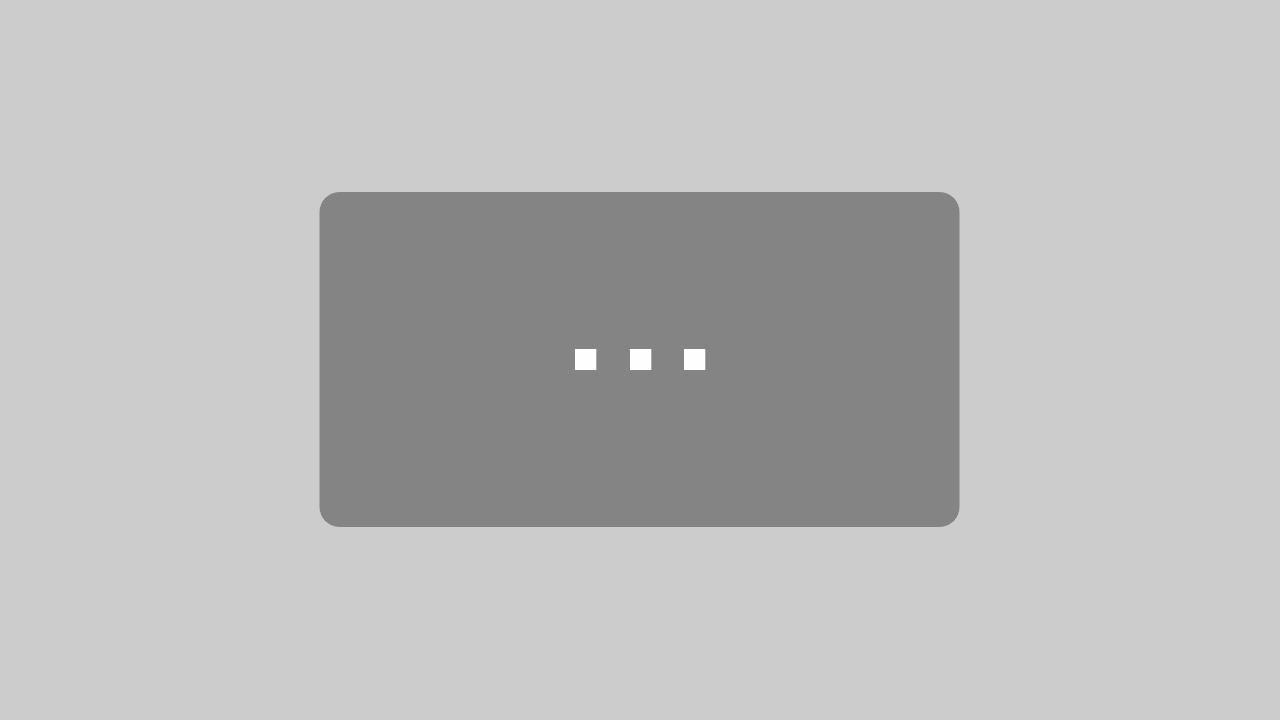

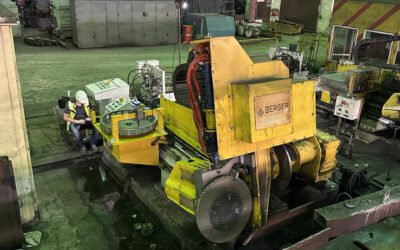

At the new Egyptian plant – the first large-scale rail rolling mill in Africa – the STEMA®-JU22 marks approximately 100-meter-long hot rails at a temperature of around 850 °C. This plant represents a major milestone in the expansion of Egypt’s infrastructure and was officially inaugurated by the Egyptian government: Watch the inauguration

In close cooperation with our client, SMS group, and the Egyptian customer, we successfully completed the commissioning in April 2025.

We would like to sincerely thank our customer and business partners for the professional and trusting collaboration!