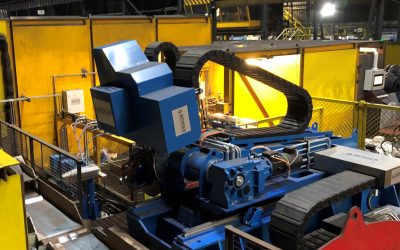

Last week BERGER Engineering received a purchase order for a new STEMA® JU 17 from Danieli. We thank our costumer Danieli again for the continued trust in our company as in the previous years of cooperation.

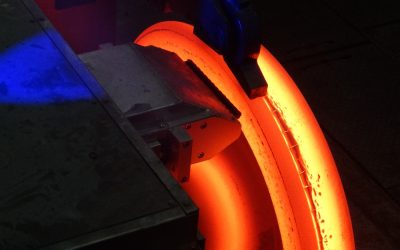

The rail stamping machine will be shipped at the end of this year to the end costumer EVRAZ North America in Pueblo, Colorado. At a speed of up to 6 m/s, it will mark 100-meter-long premium-quality rails of the most modern rail rolling mill in North America. It has a production capacity of 670,000 short tons and the rails will be manufactured according to AREMA specifications.

More information: https://www.danieli.com

The decisive factors for the buying decision were the references and the know-how of Berger Engineering with rail stamping machines. The stamping machine STEMA is by far the worlds most used and most reliable marking machine for rails. We look forward to commissioning in the USA next year!