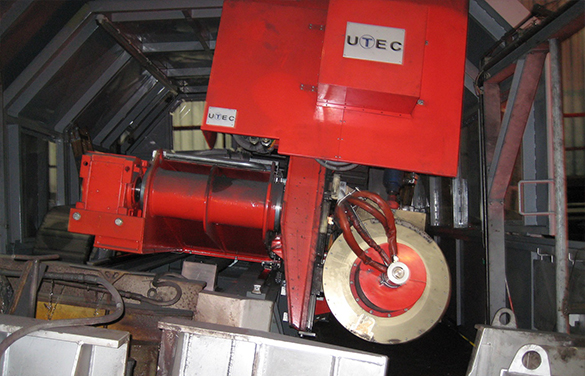

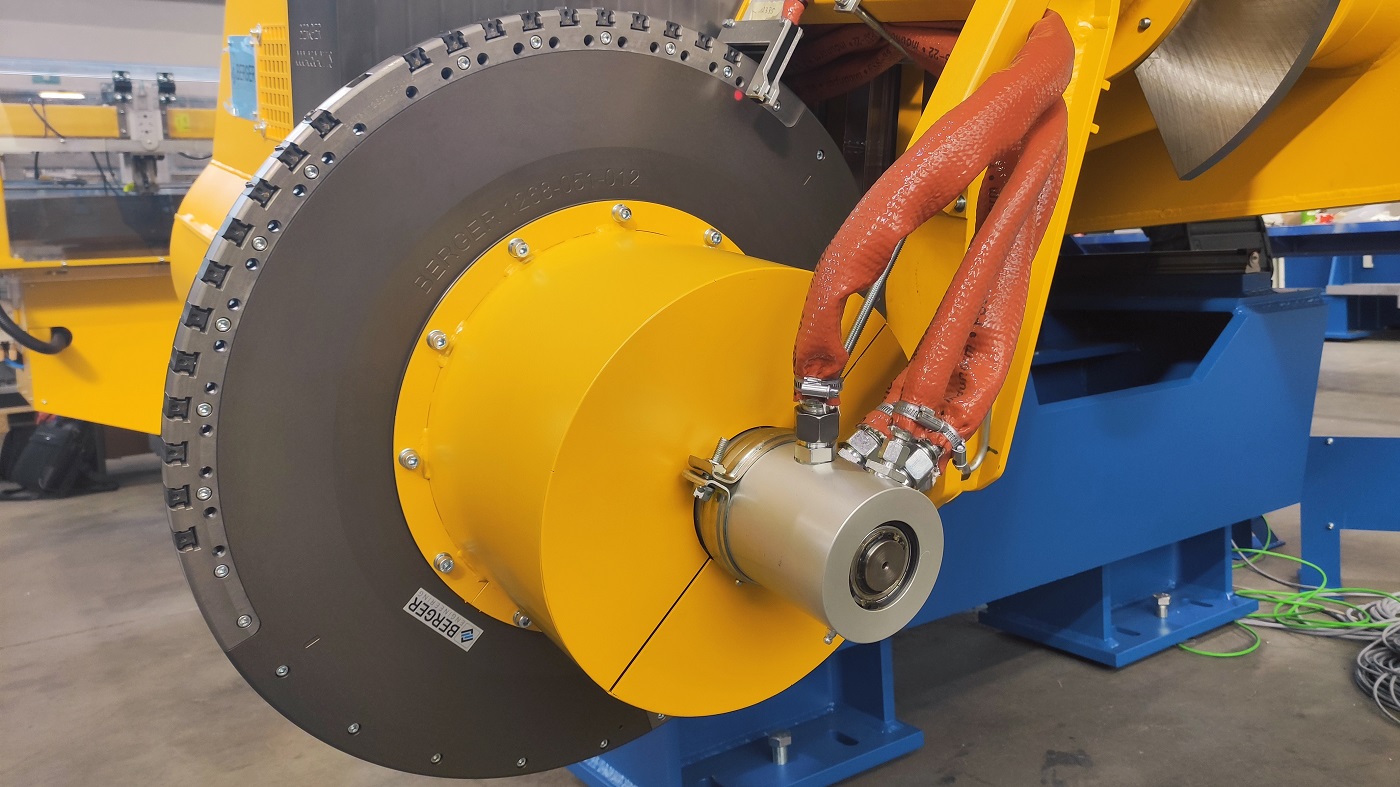

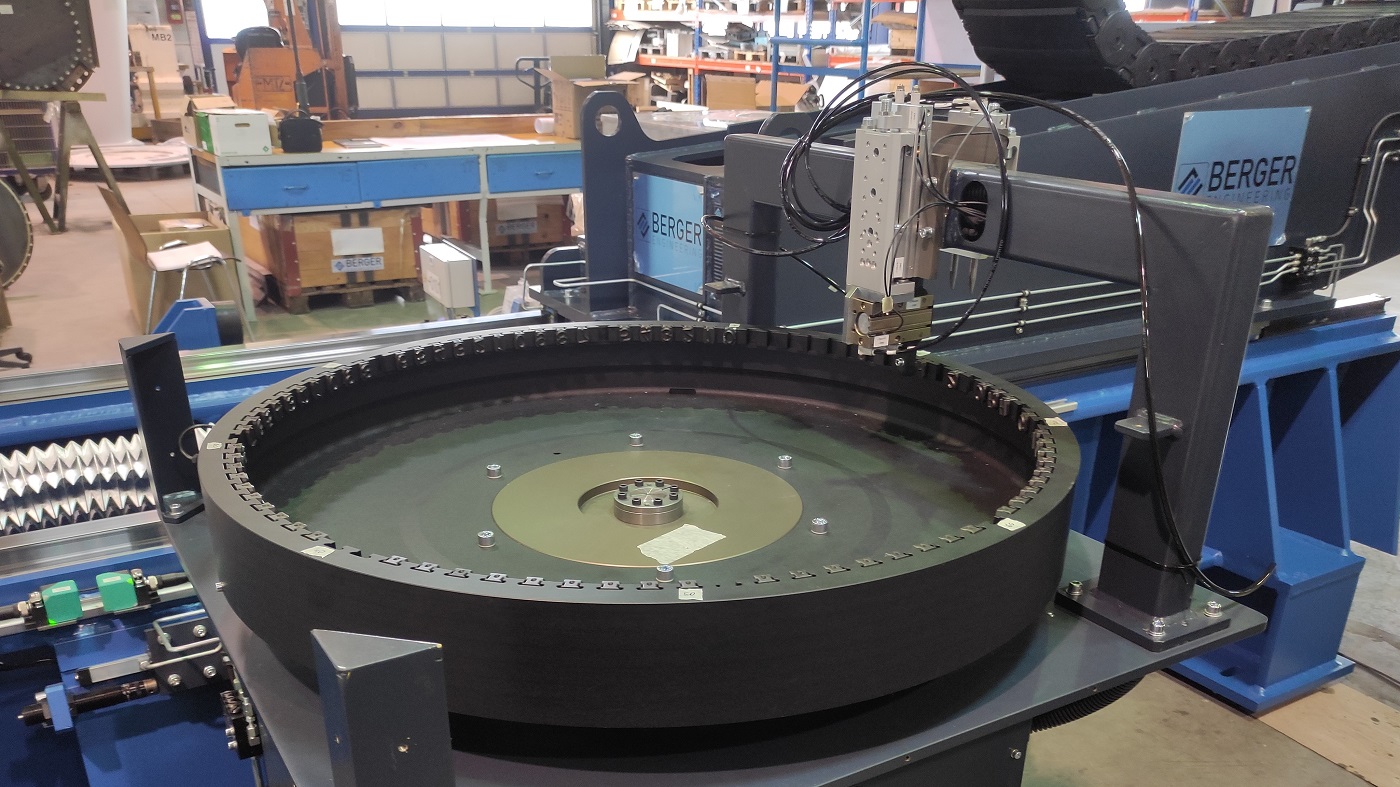

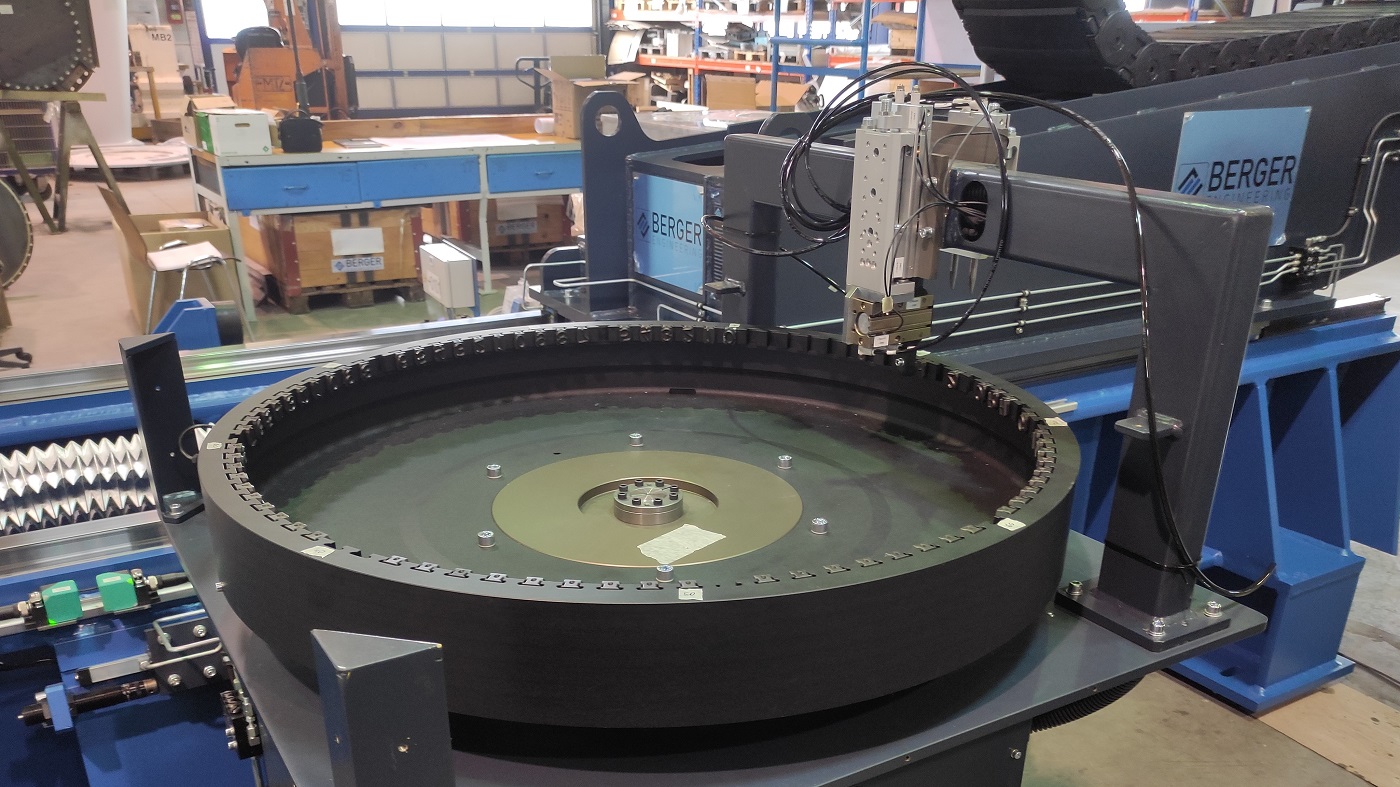

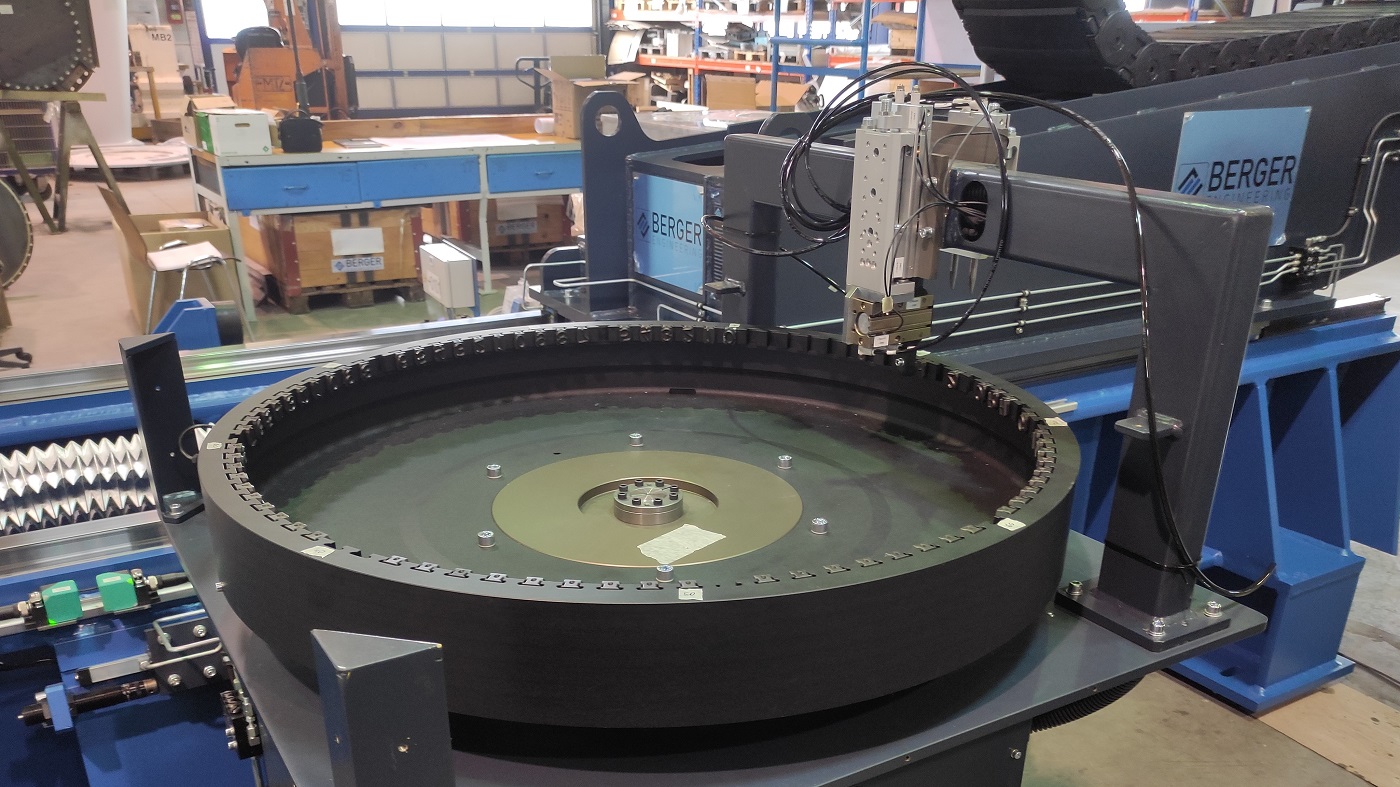

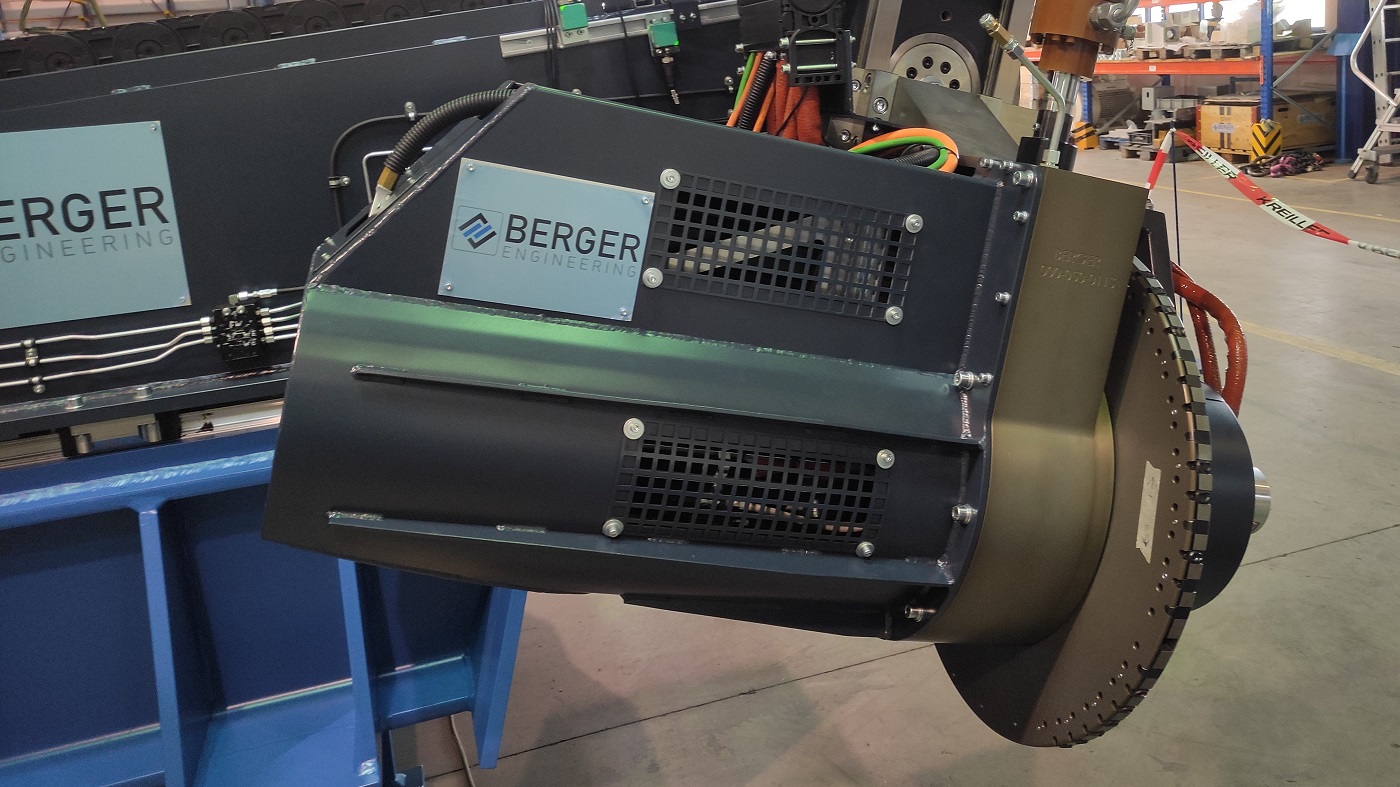

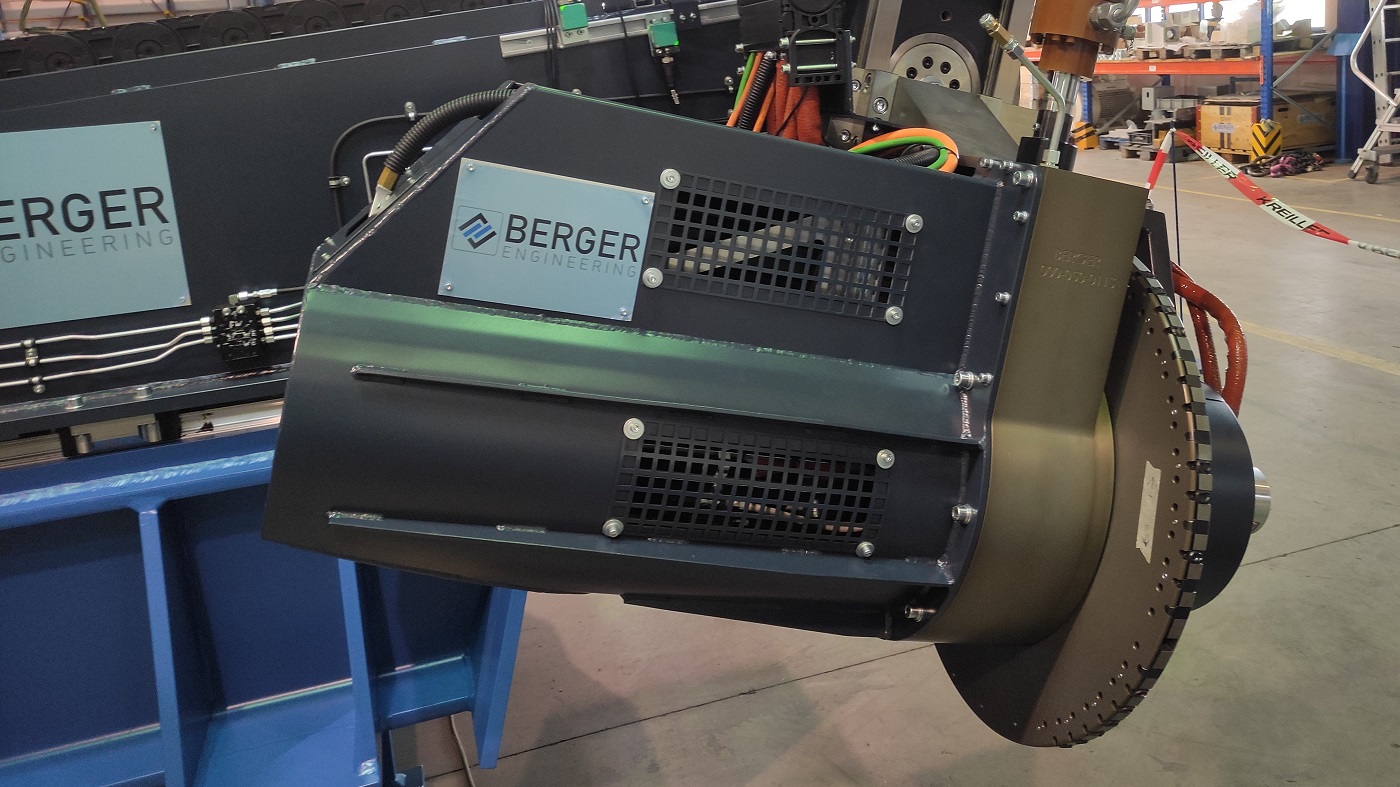

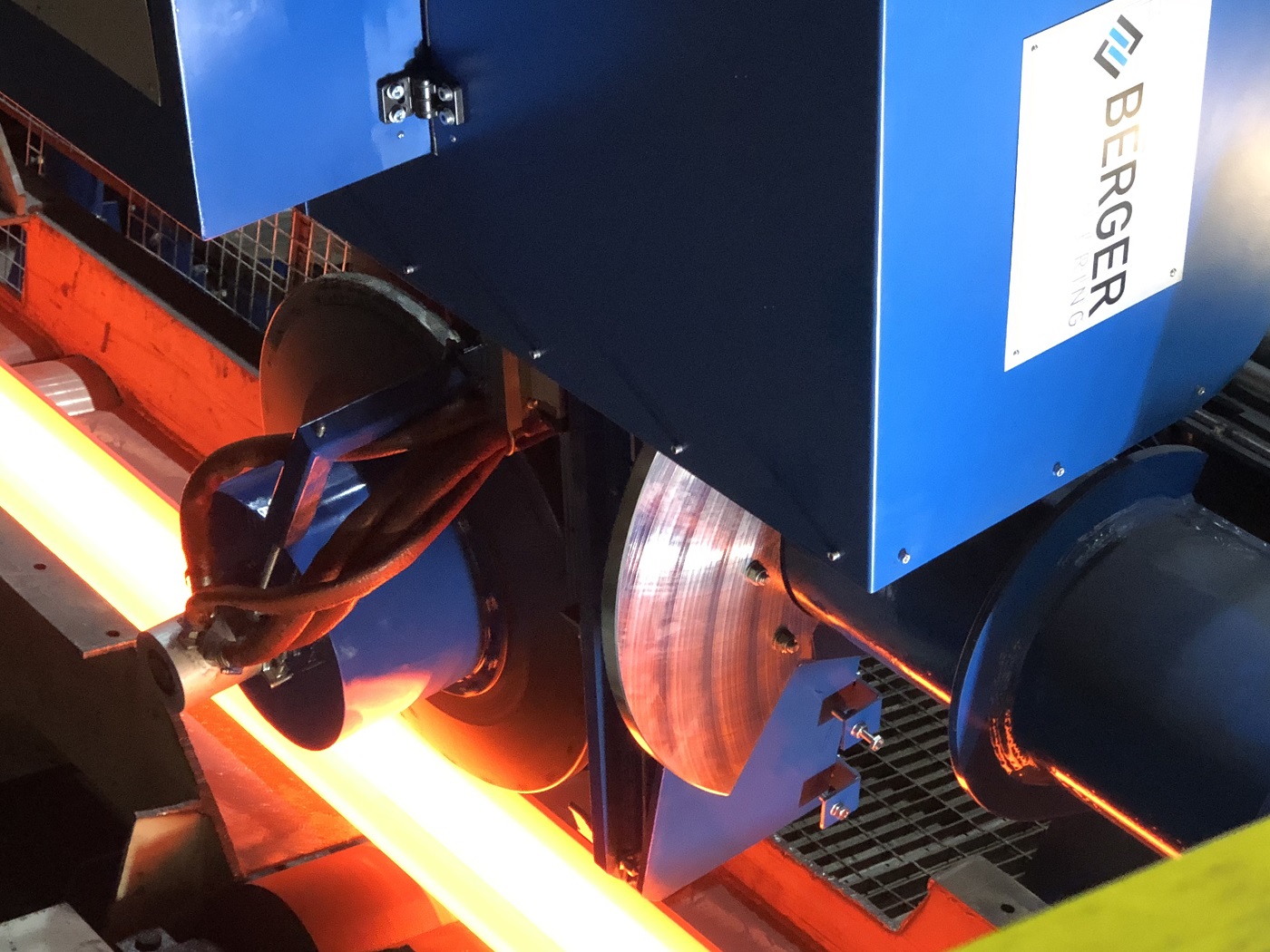

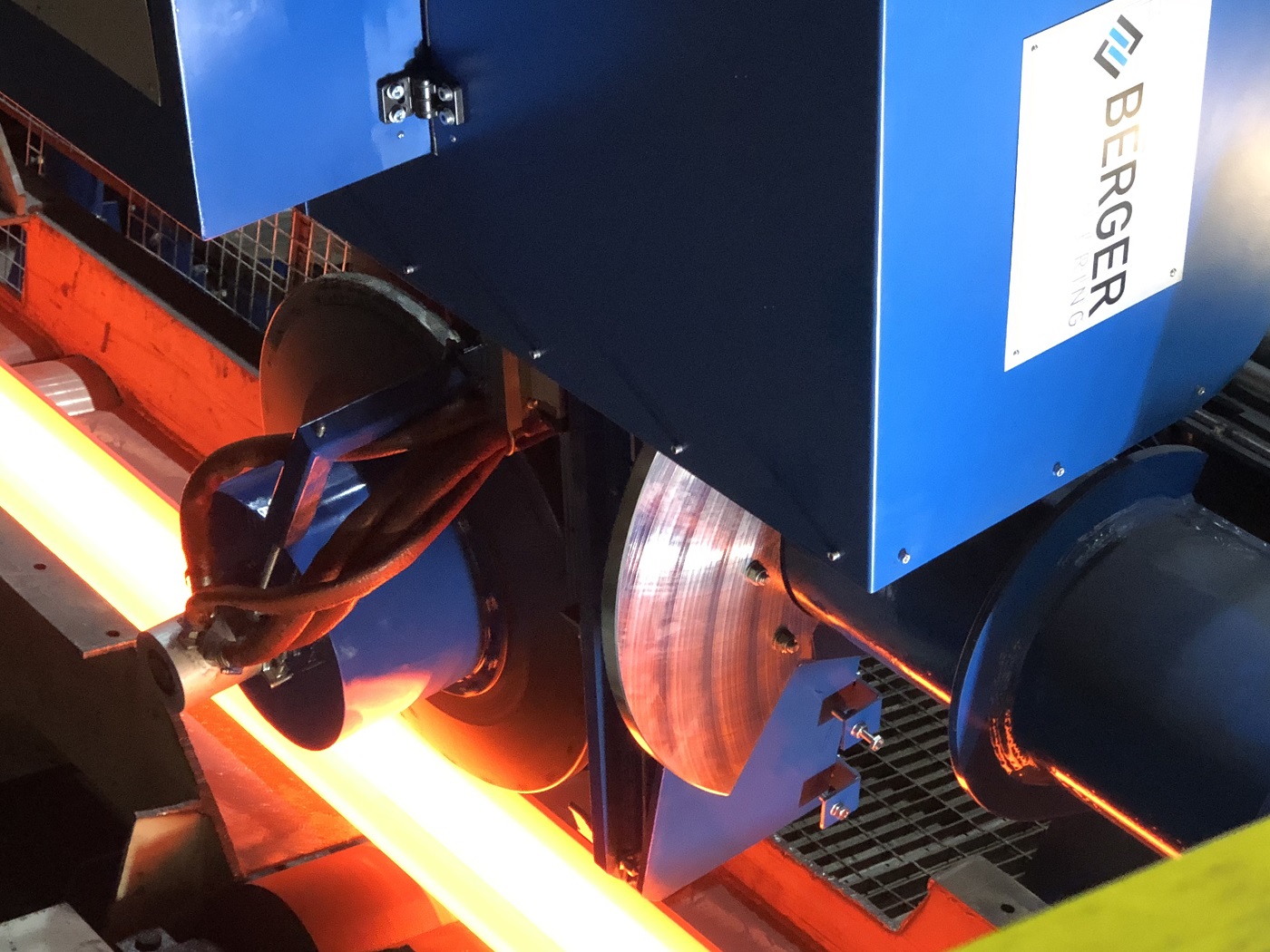

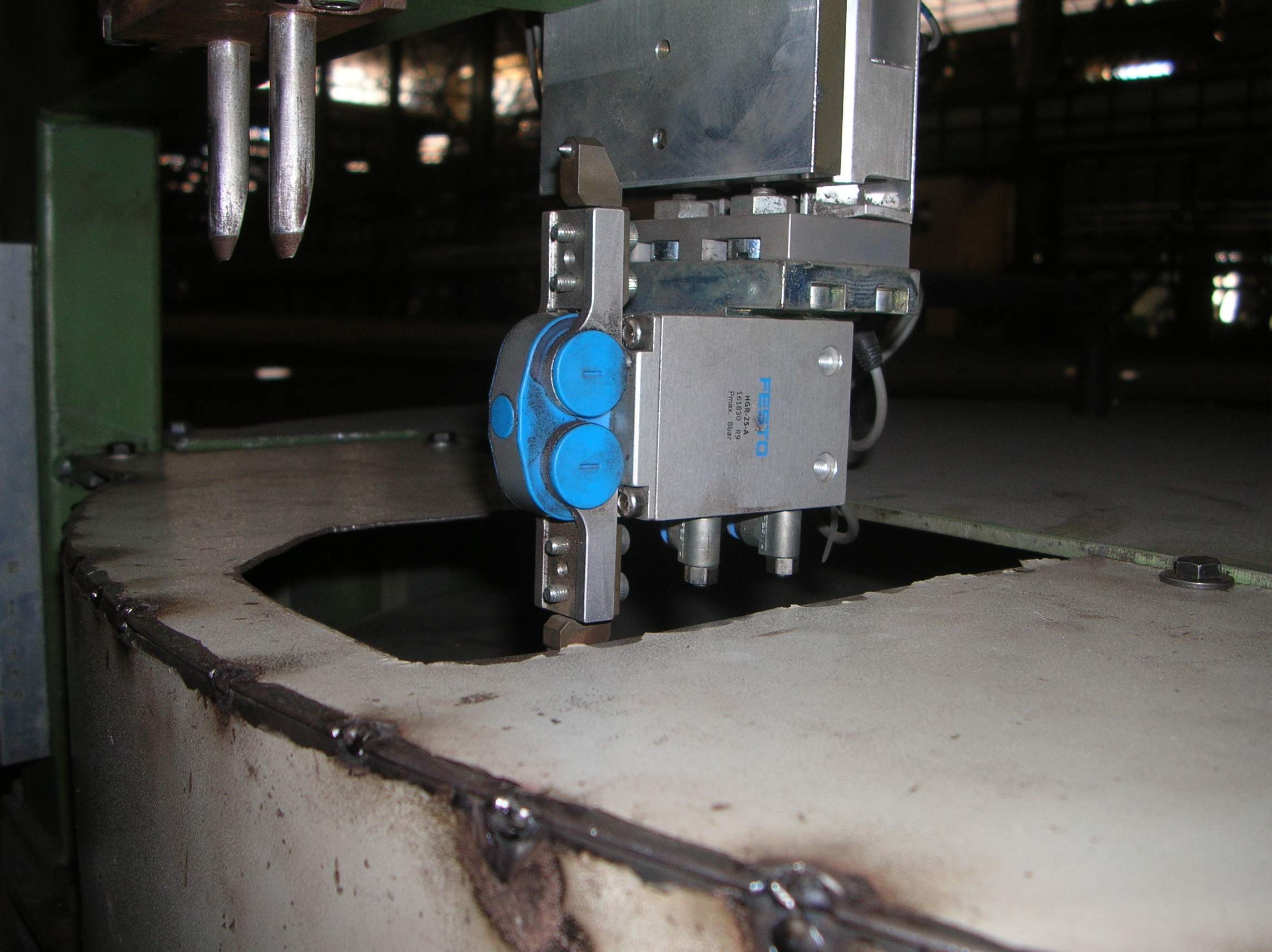

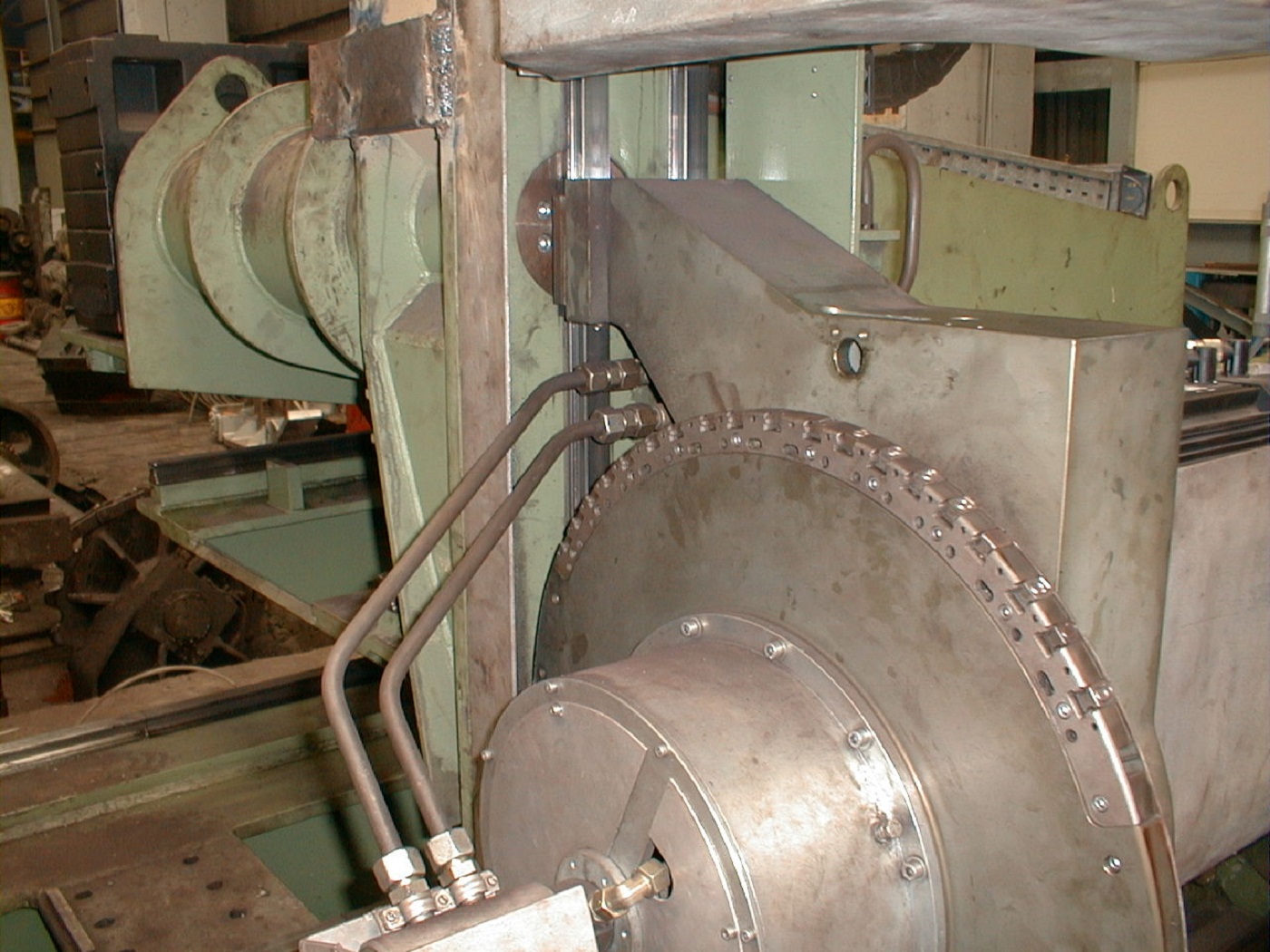

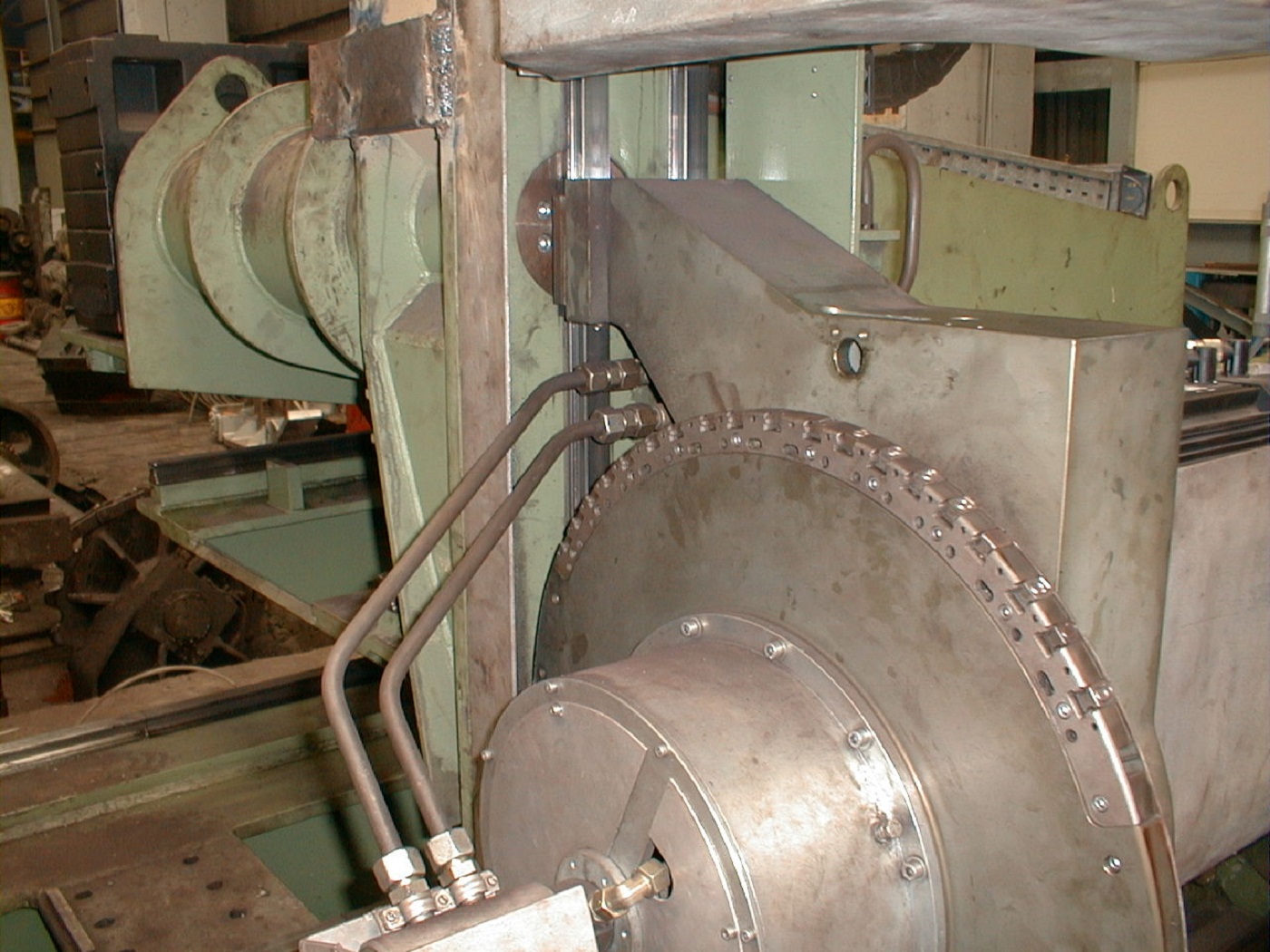

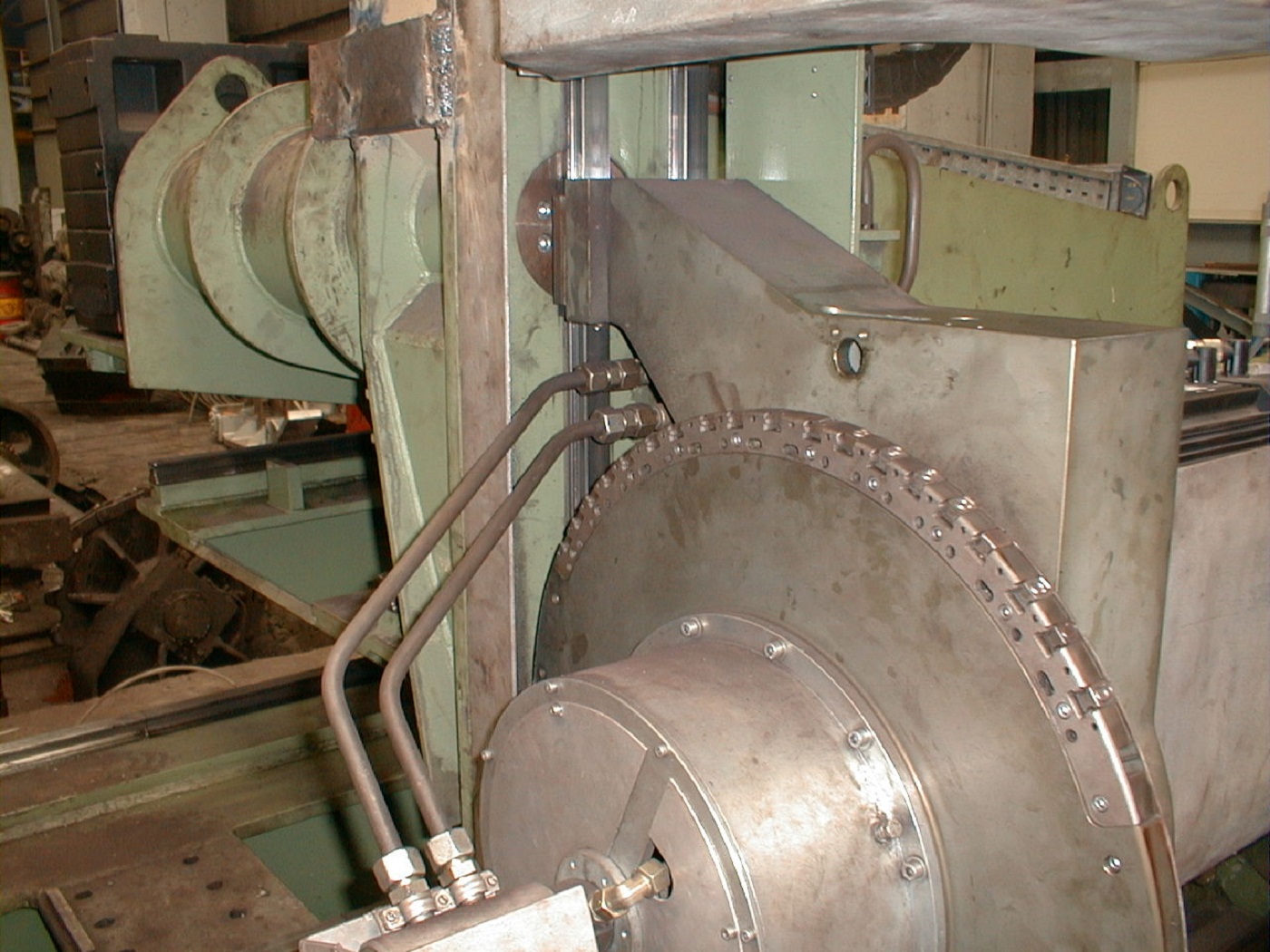

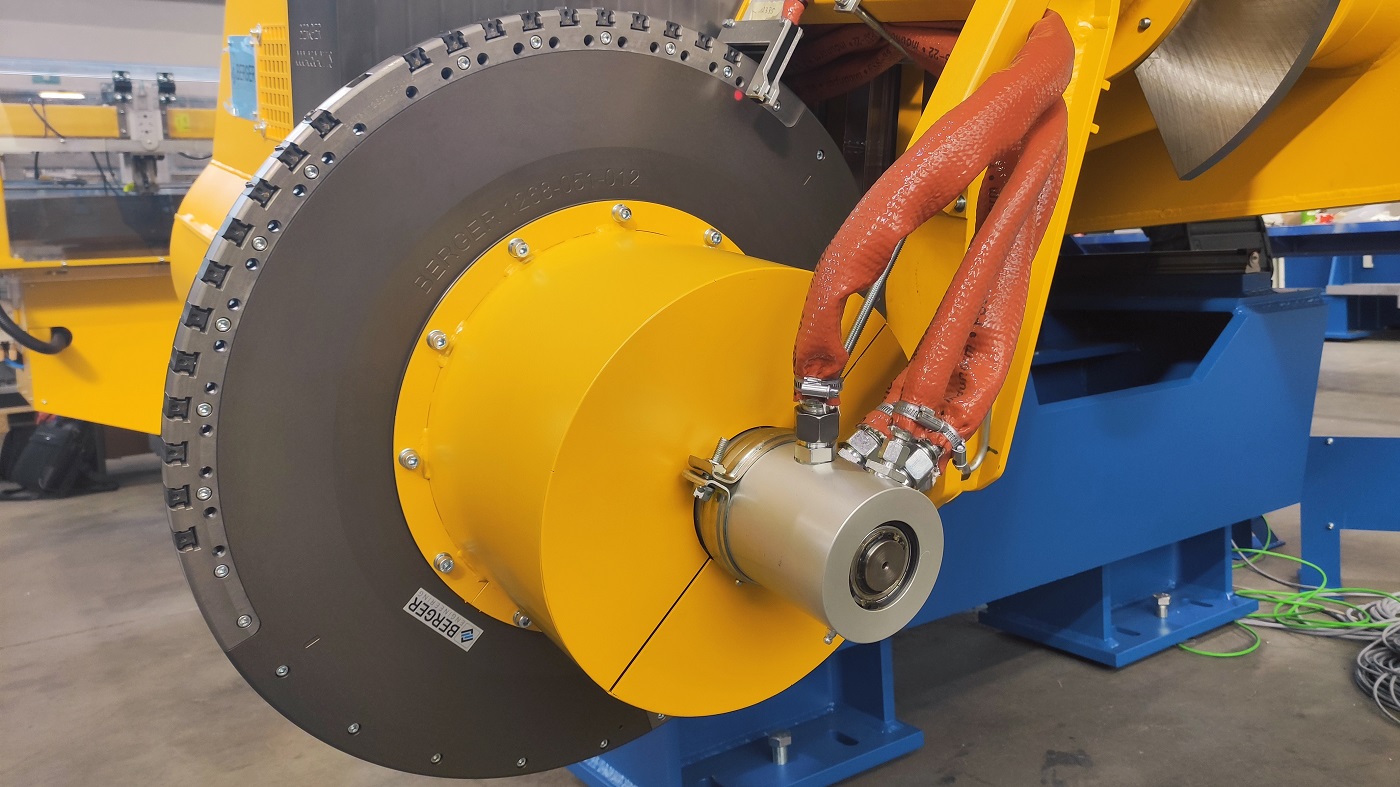

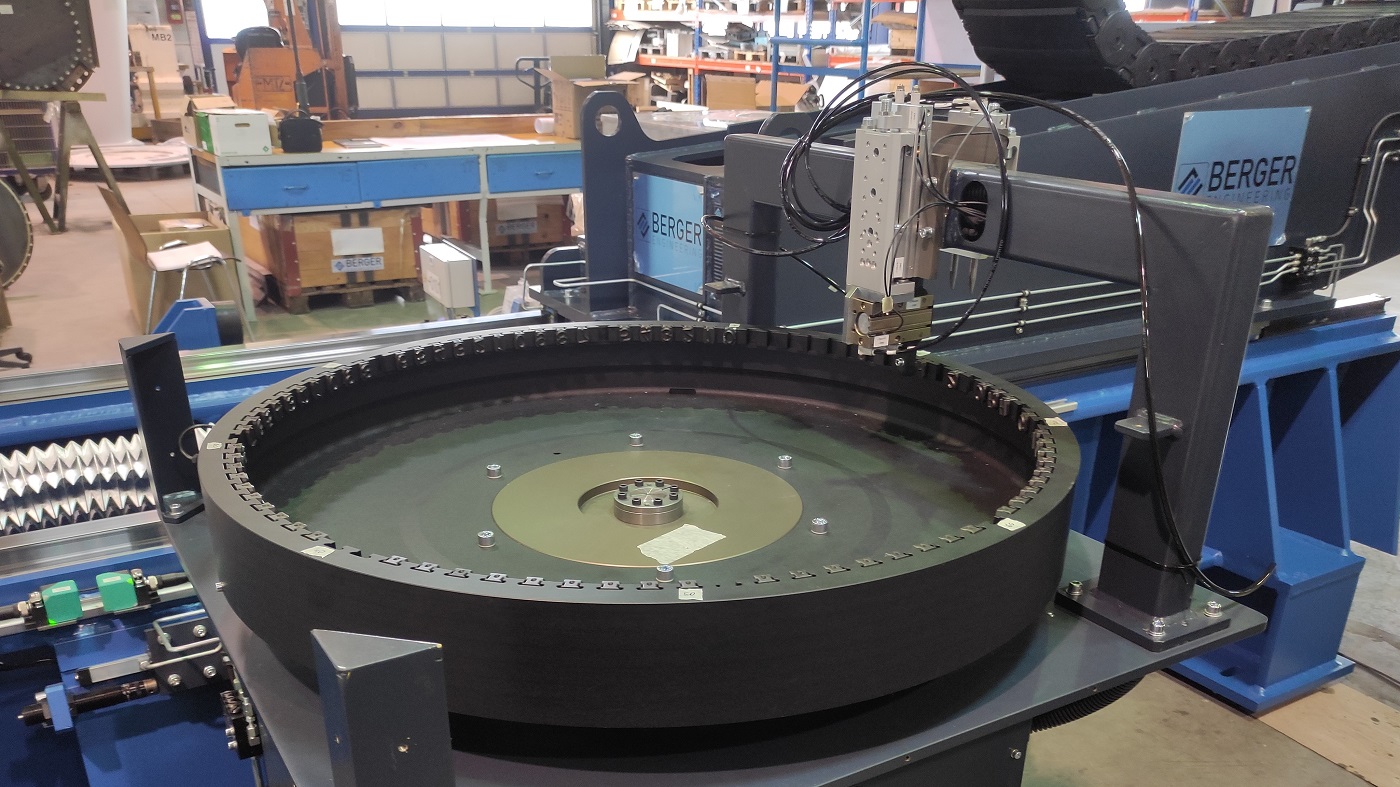

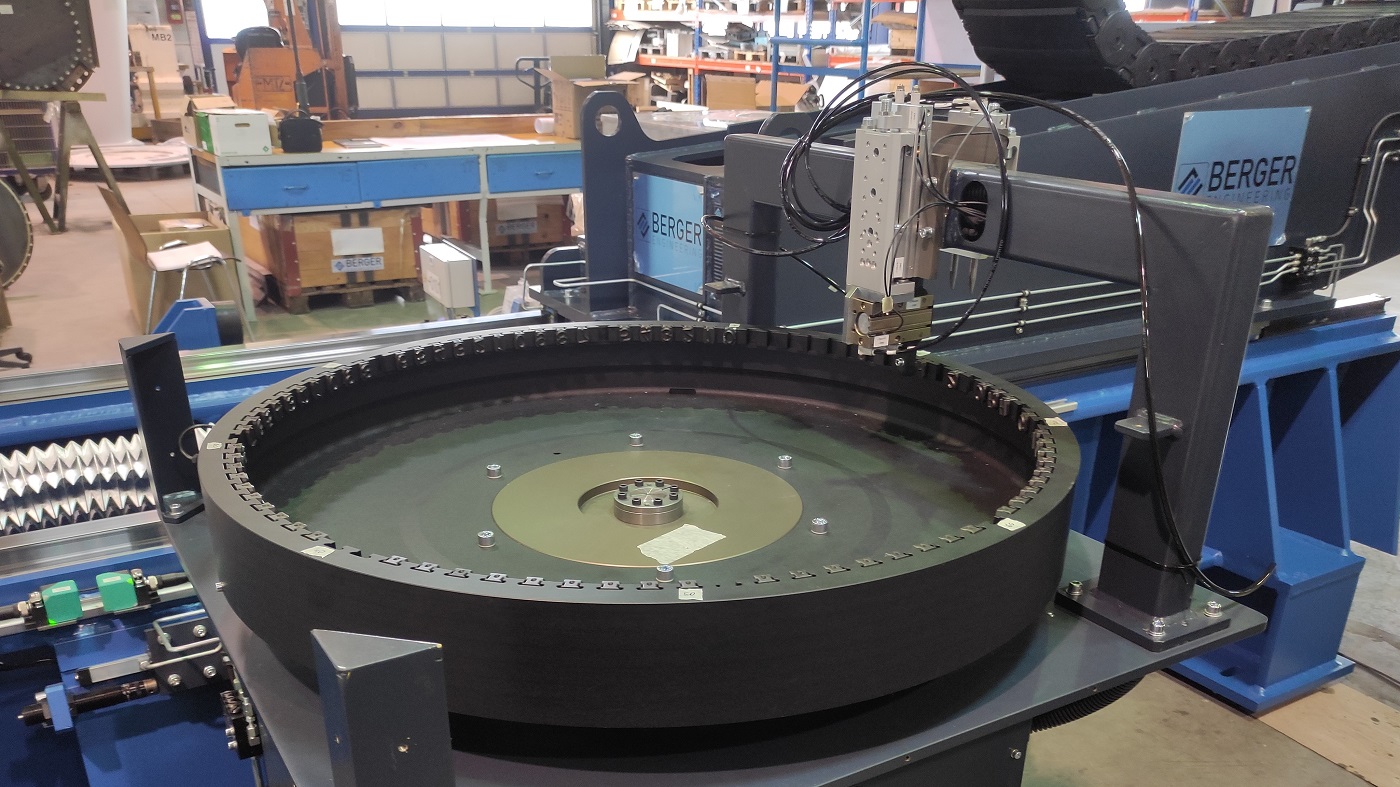

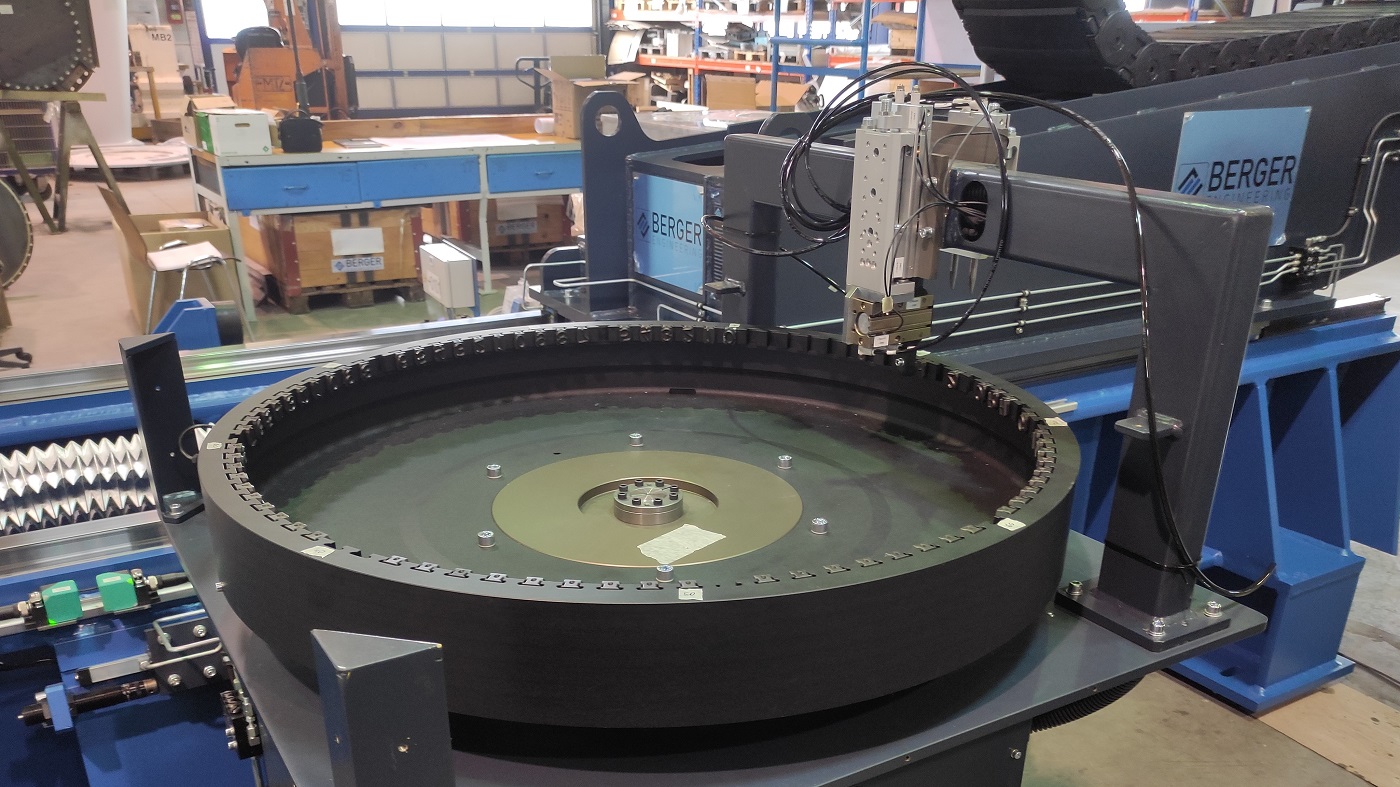

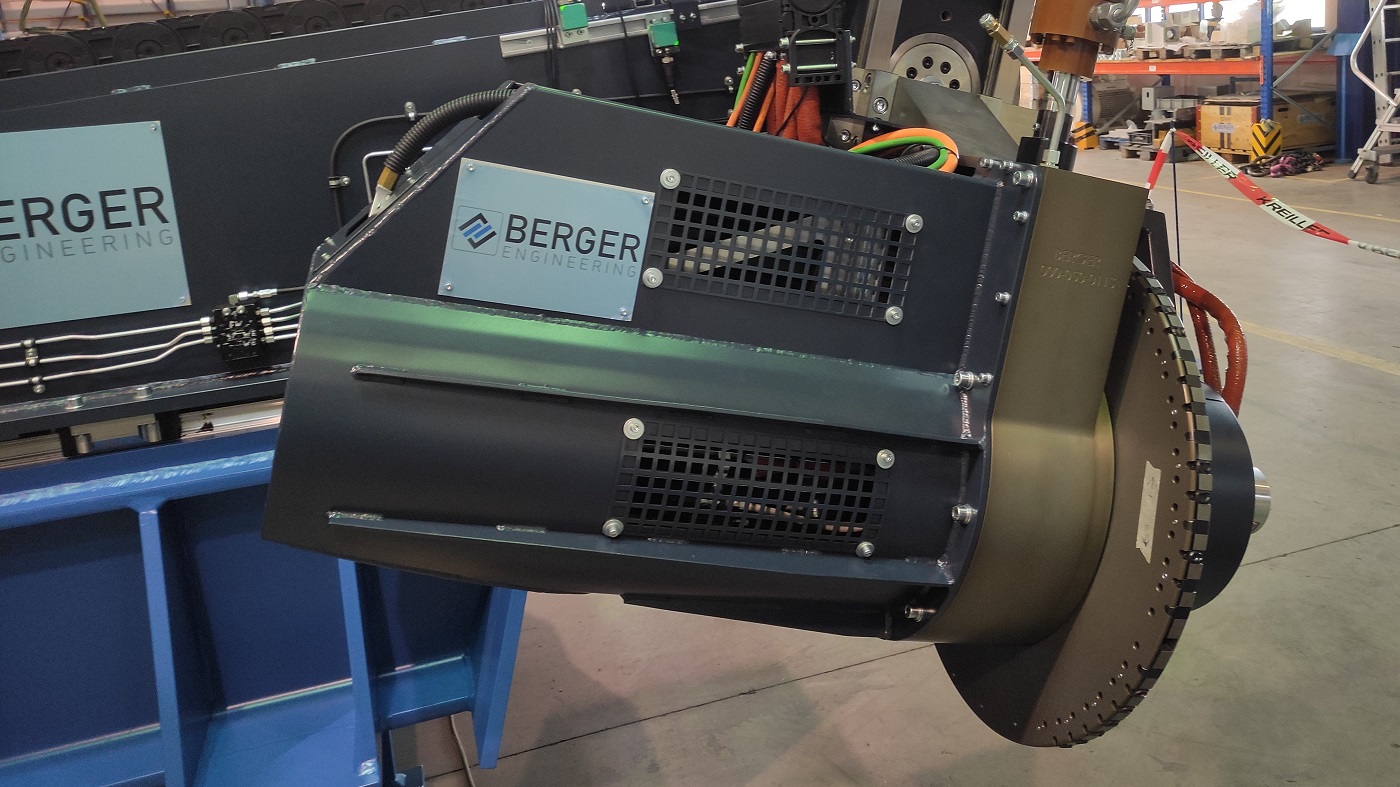

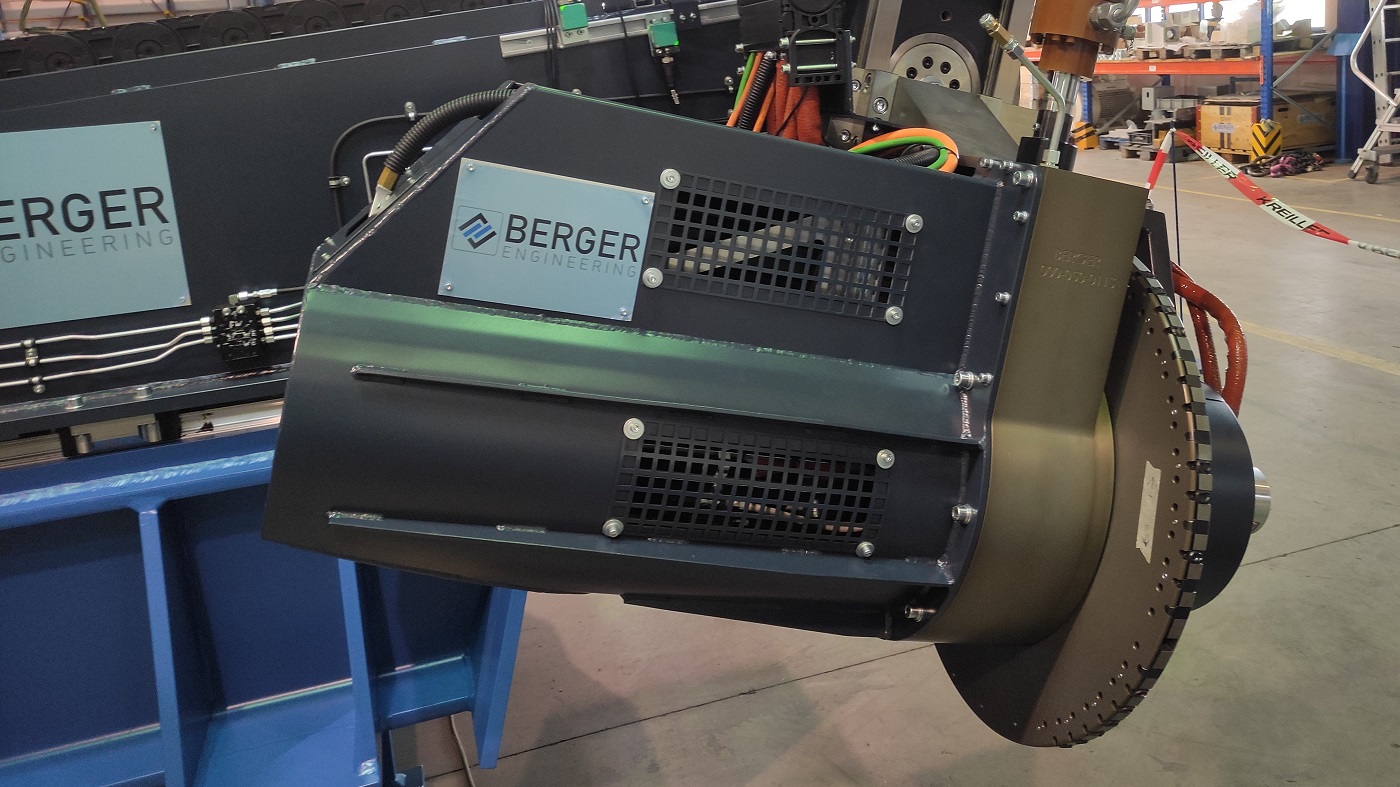

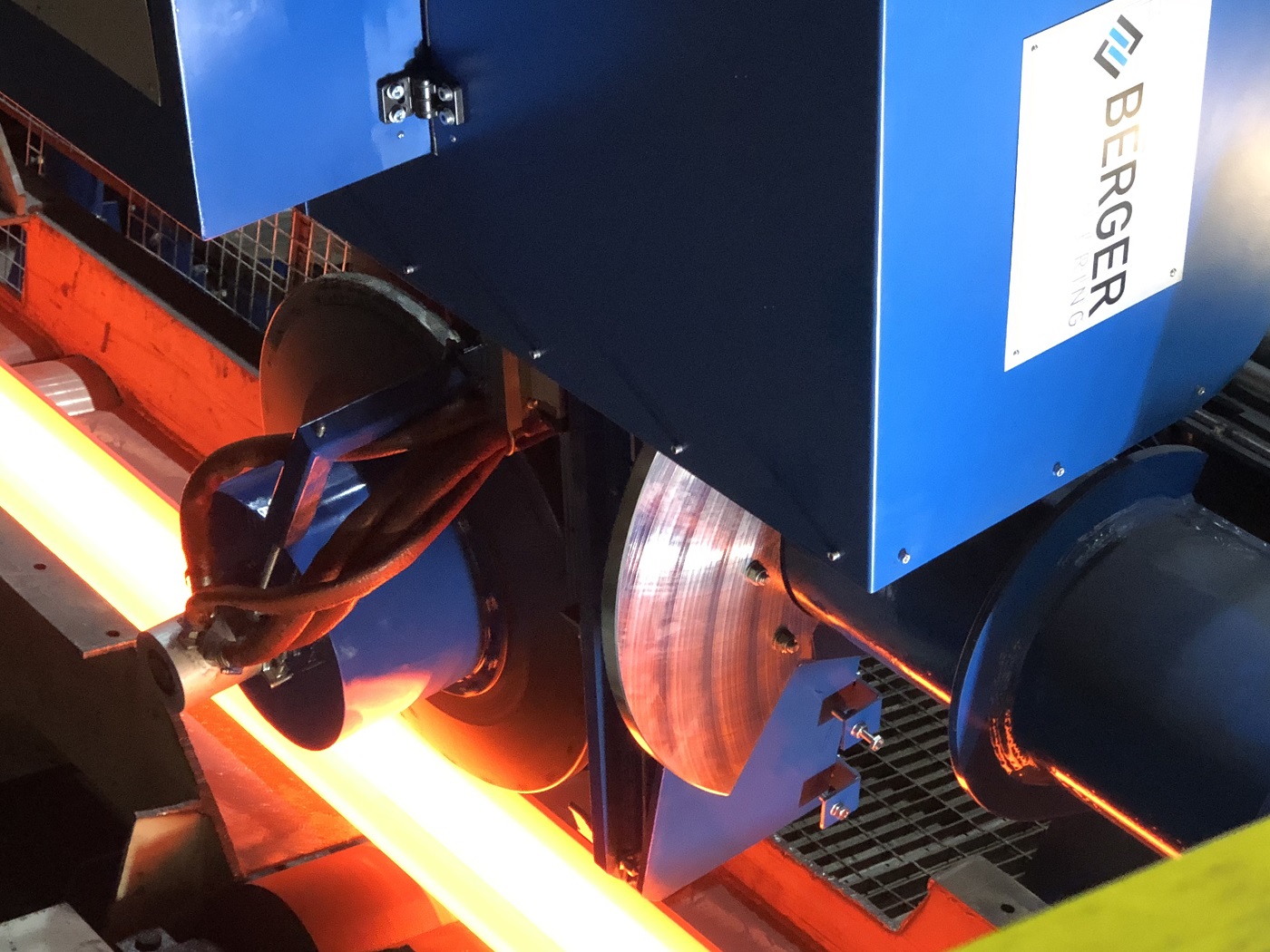

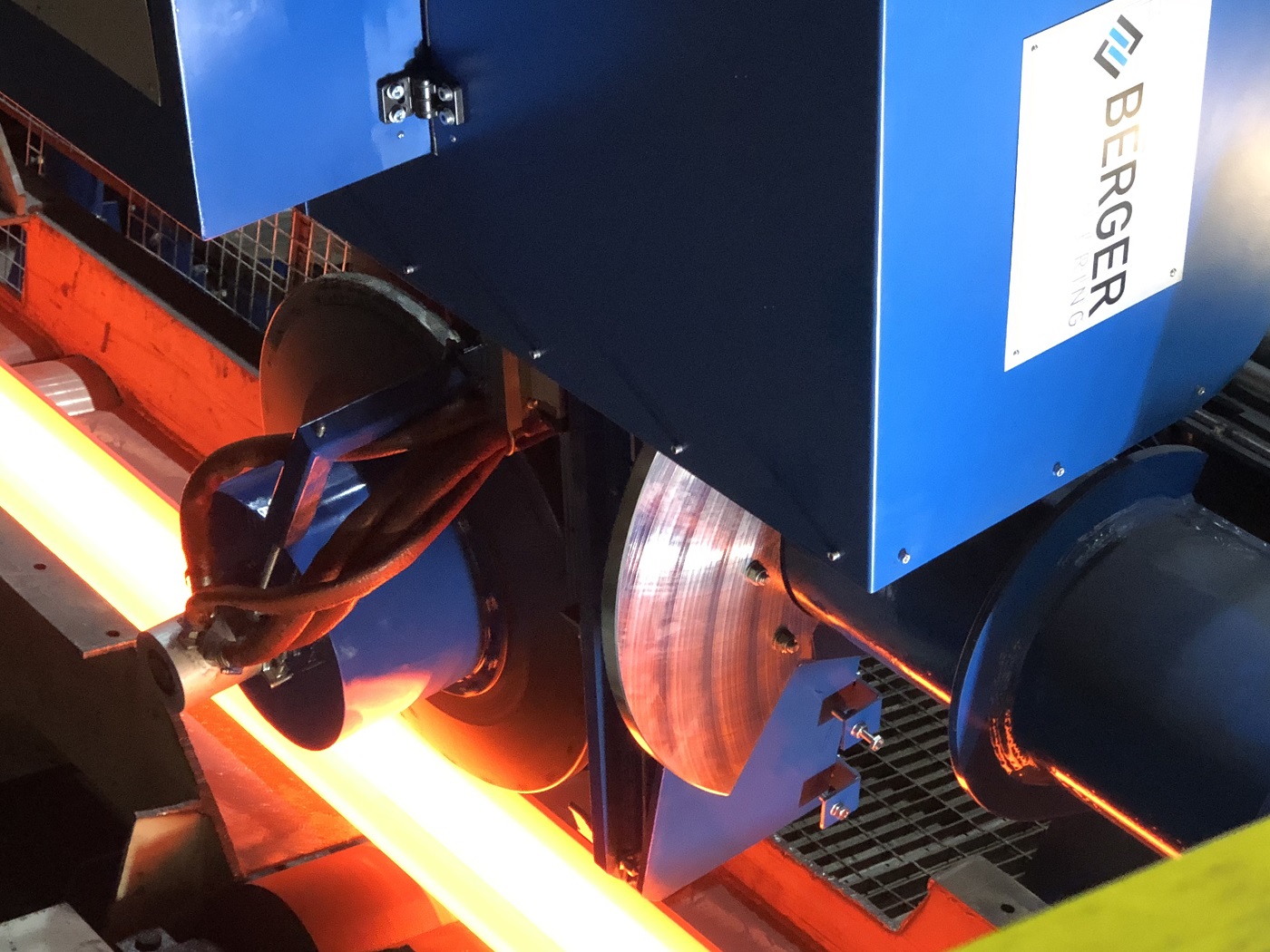

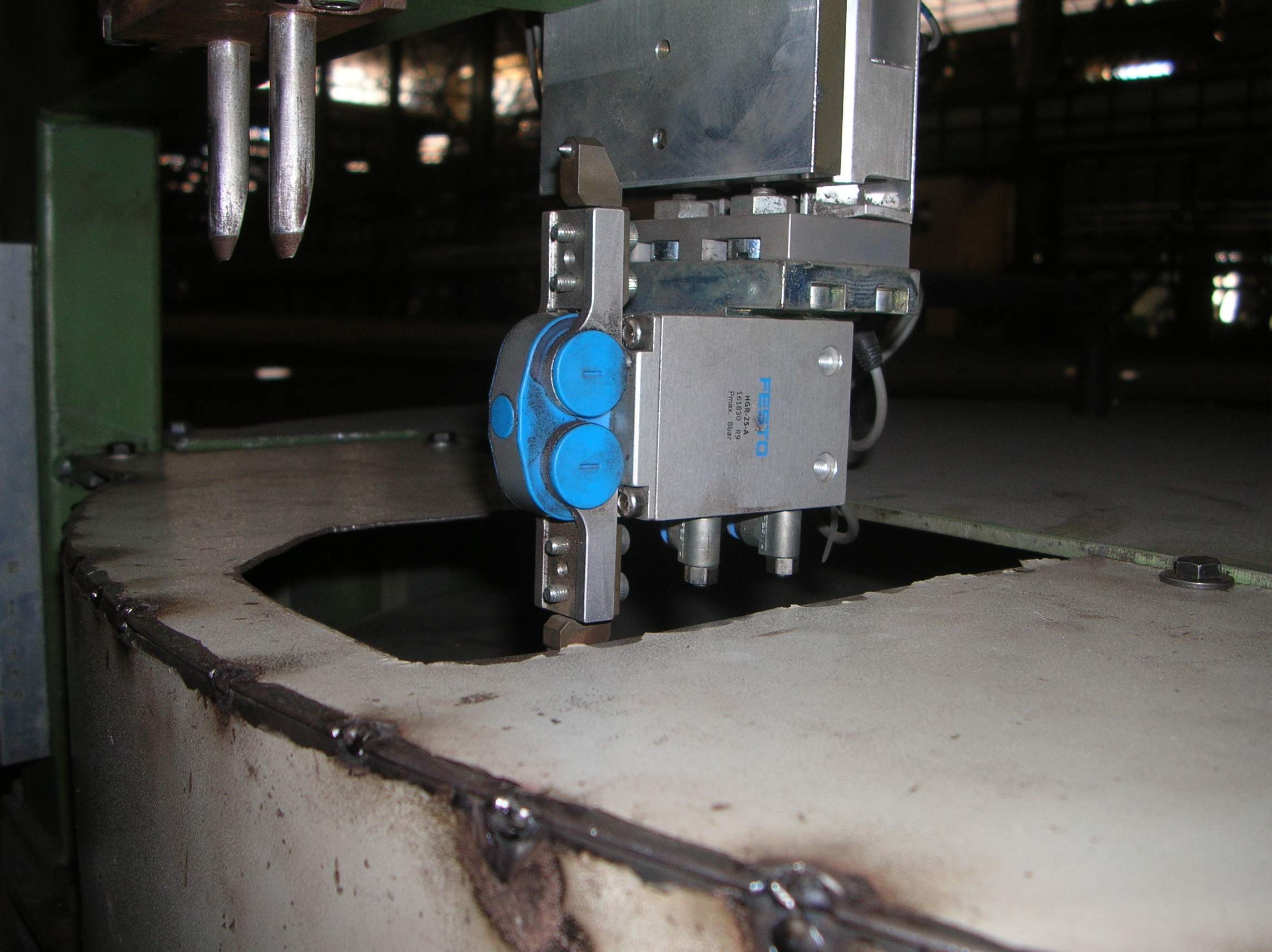

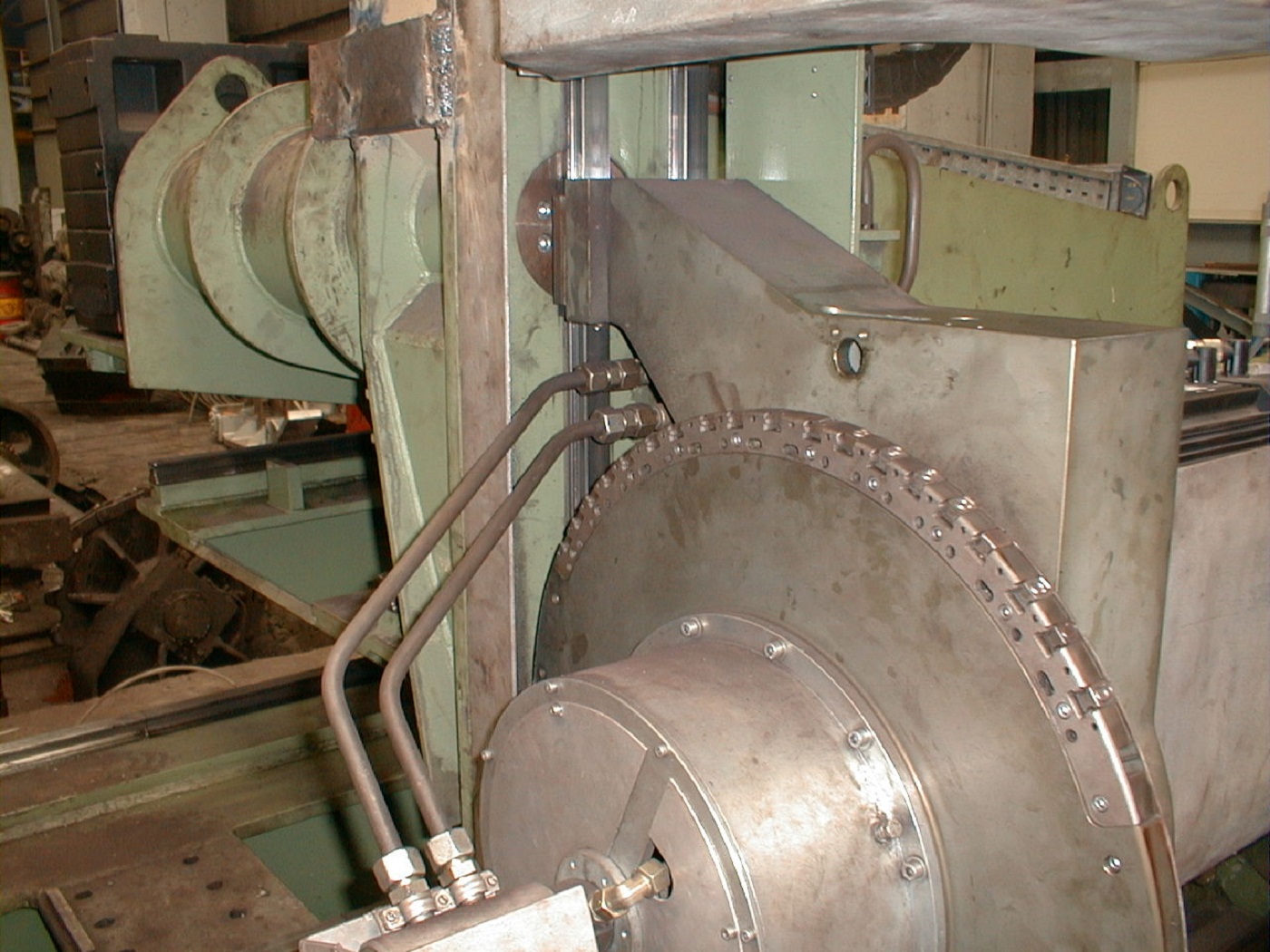

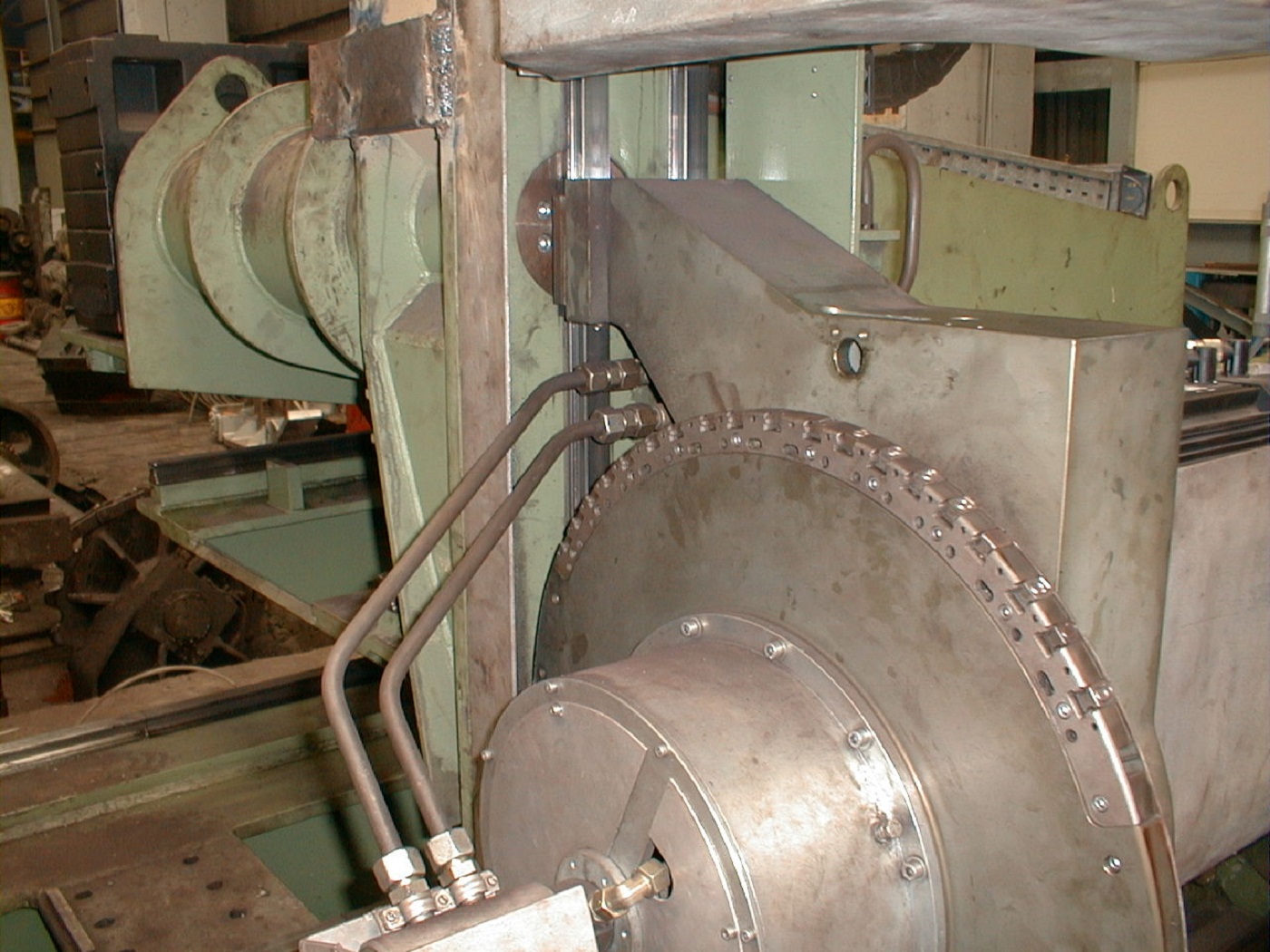

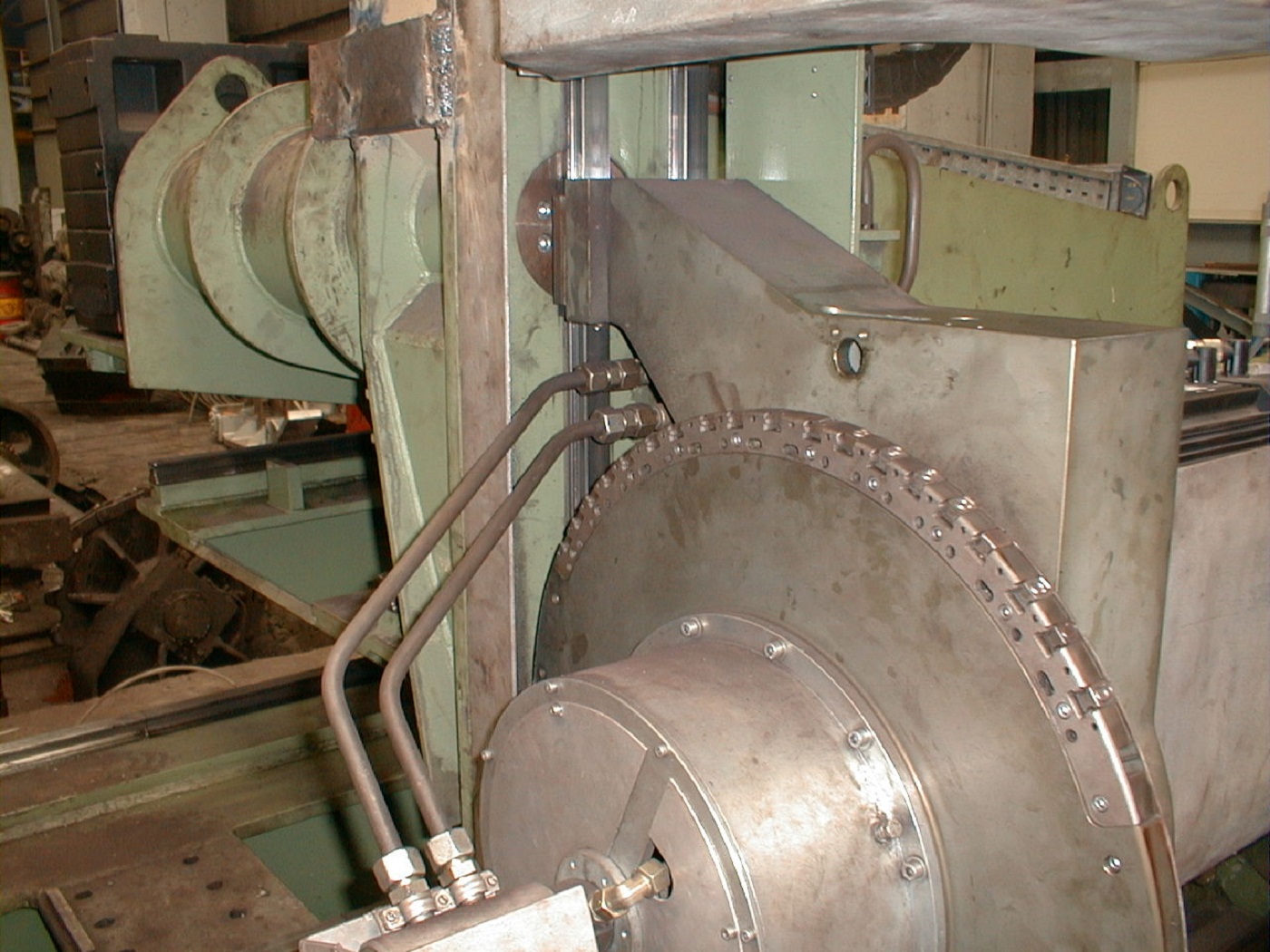

Rail Stamping Machines from Berger Engineering

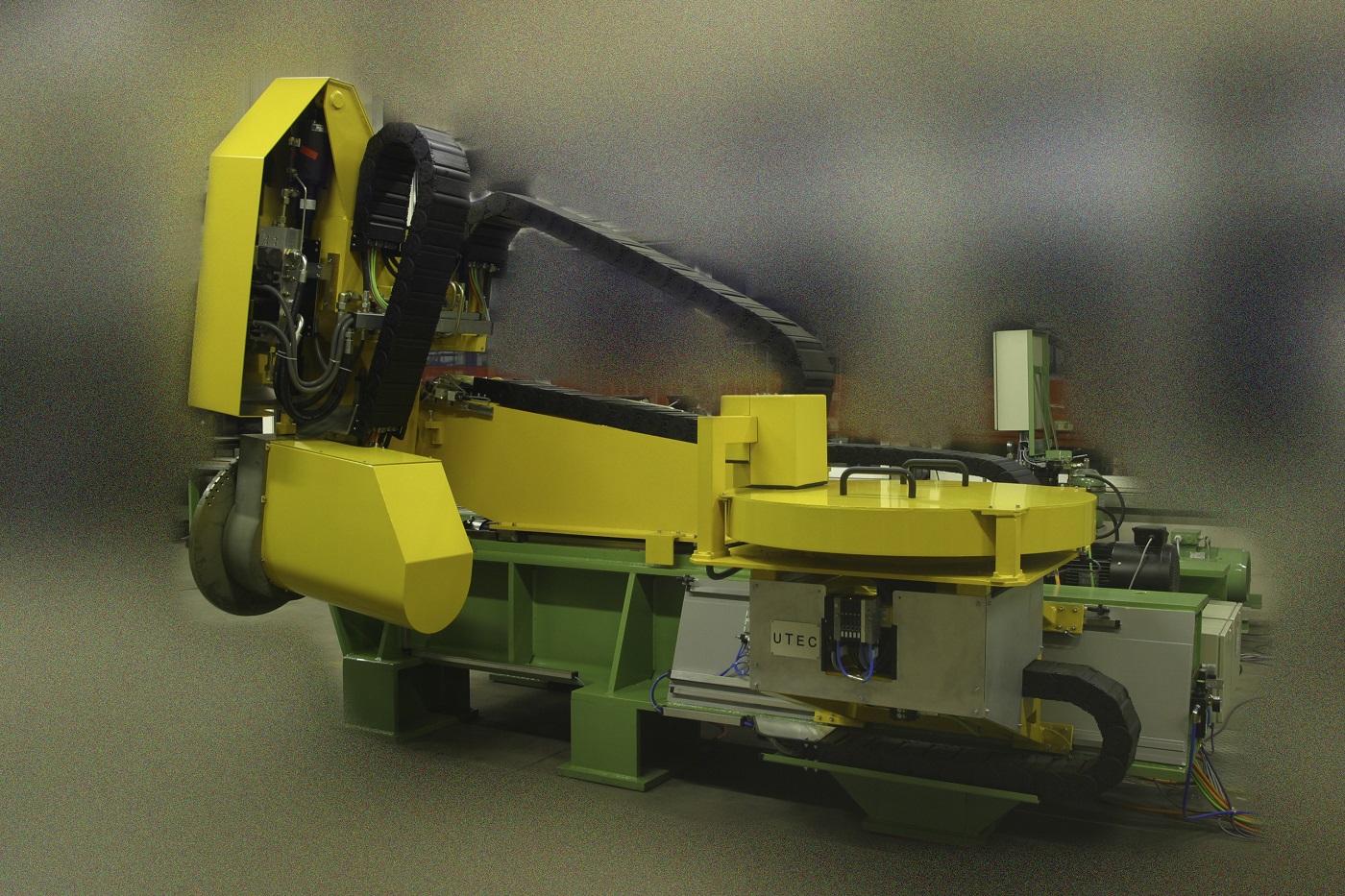

We are the leading company for the production of rail stamping machines.

Because of the specialization on marking machines and stamping machines für railway rails, metro rails and crane rails we succeeded in getting the leadership for this kind of technology.

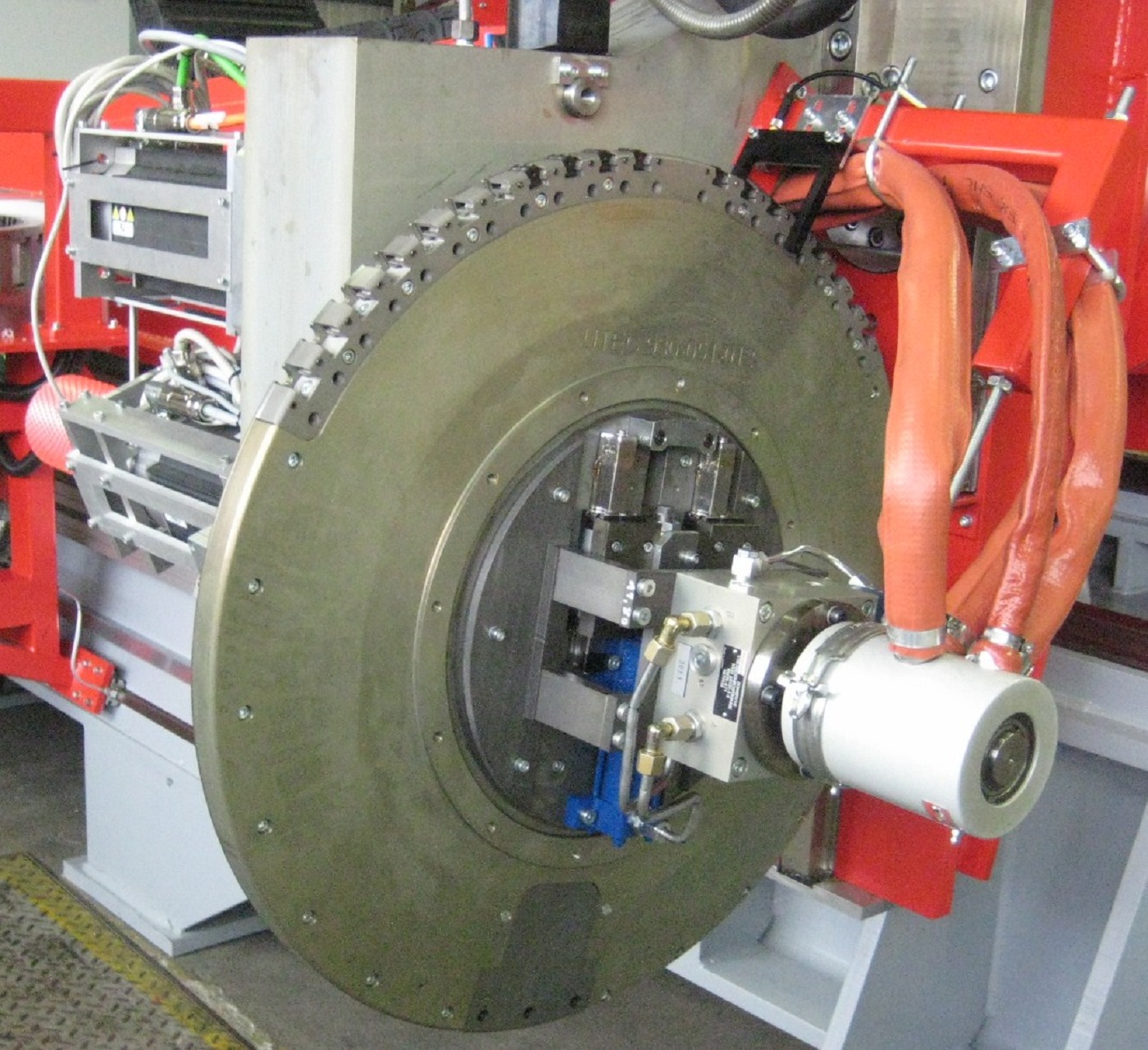

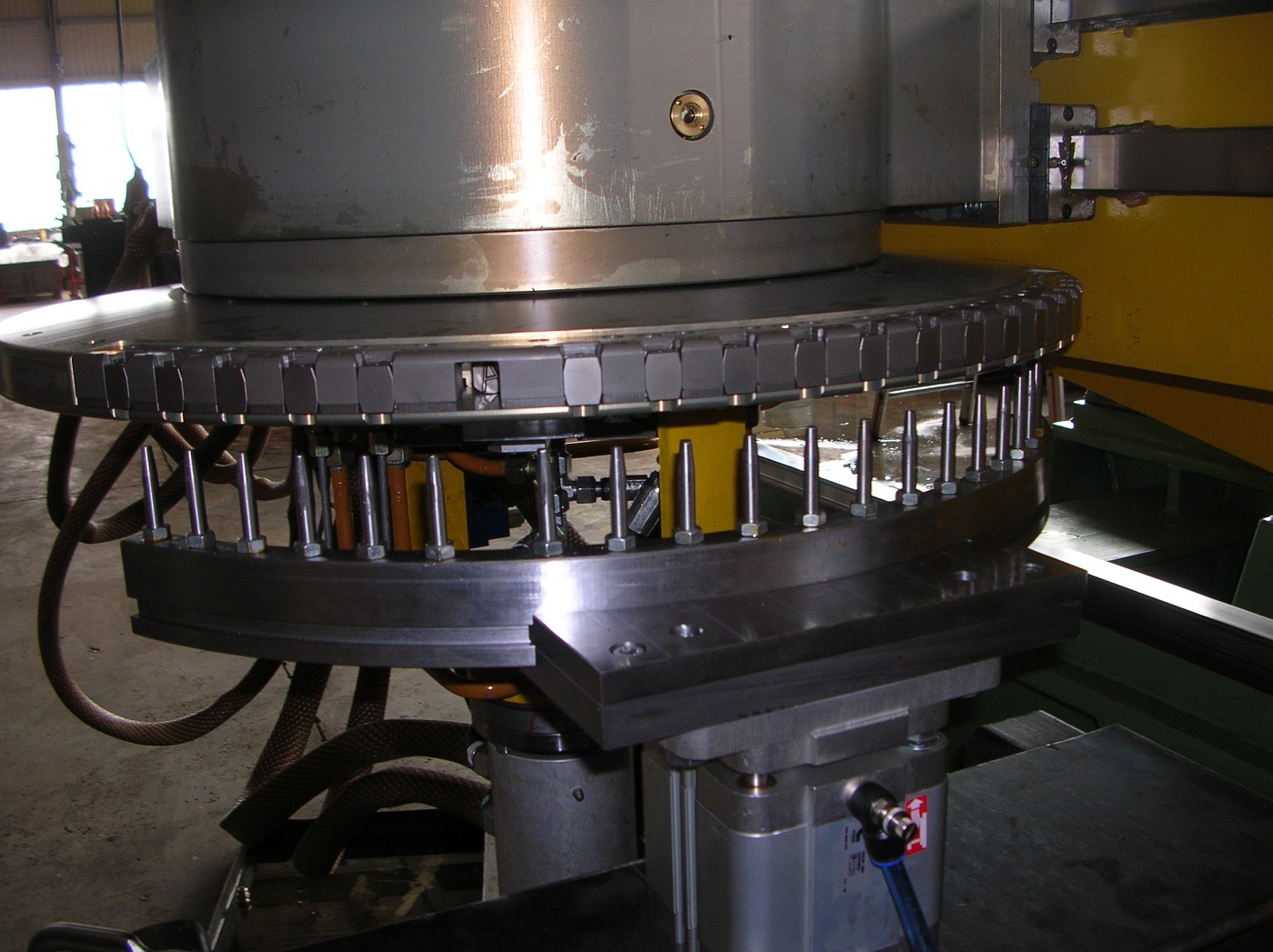

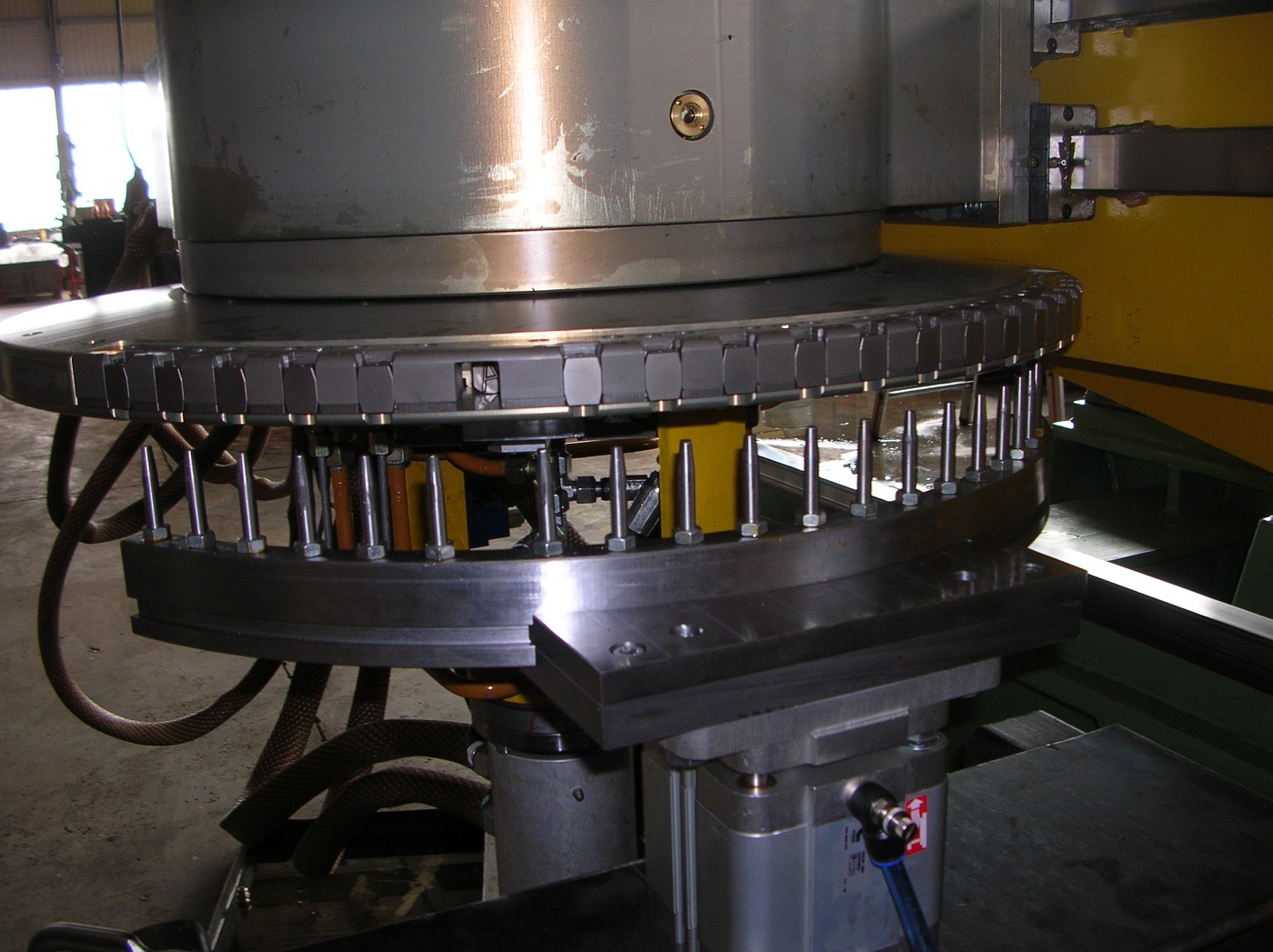

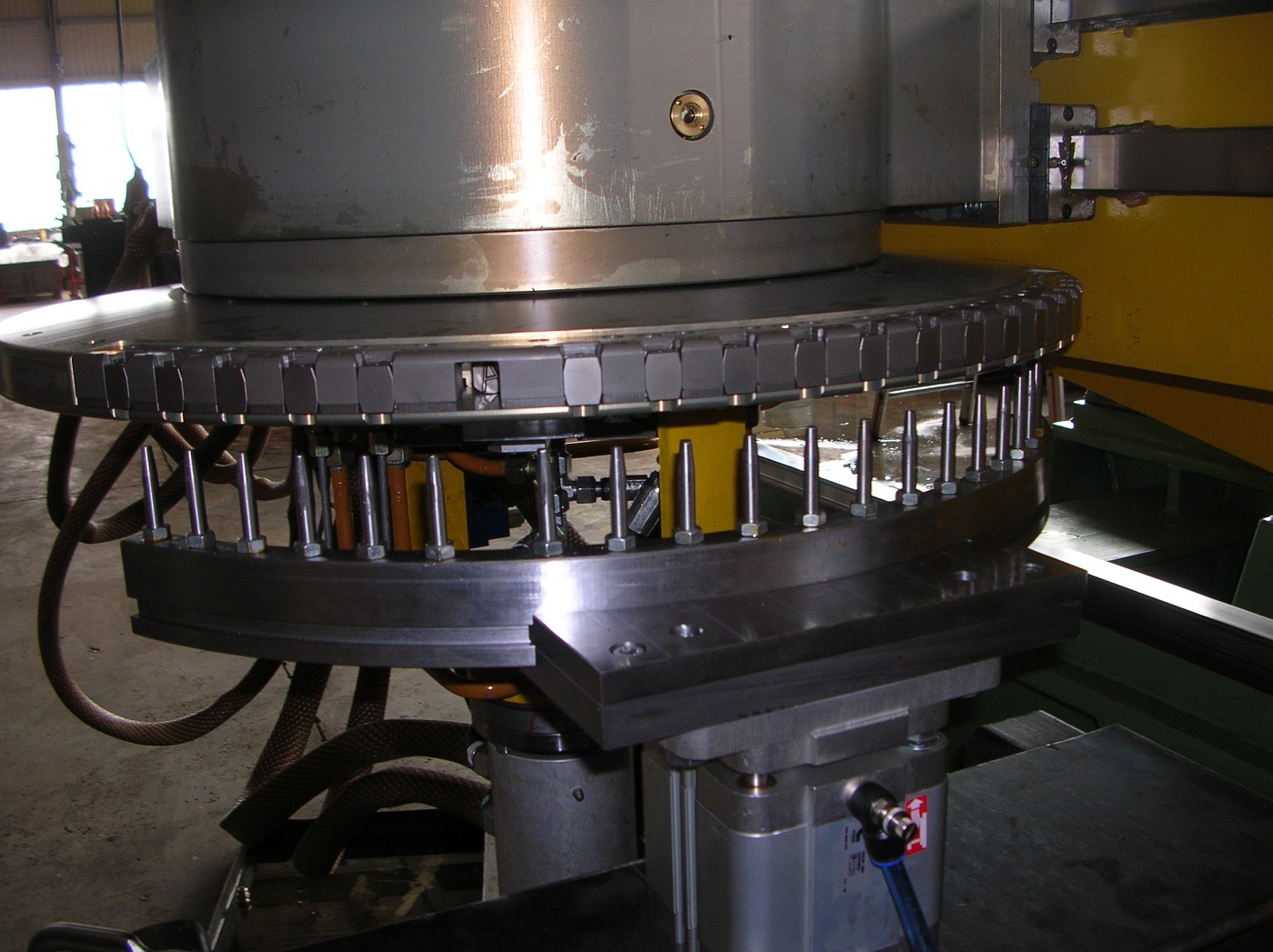

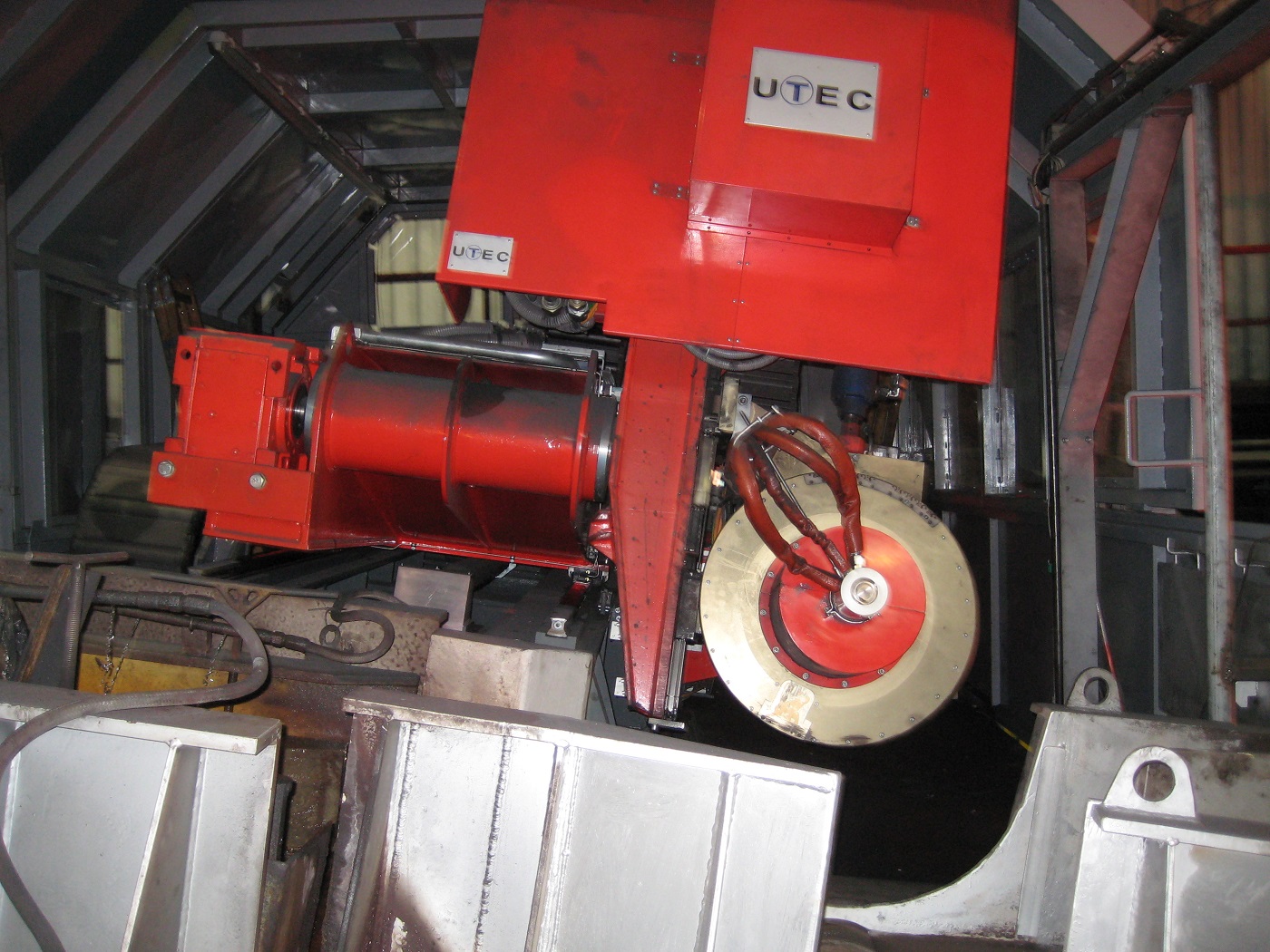

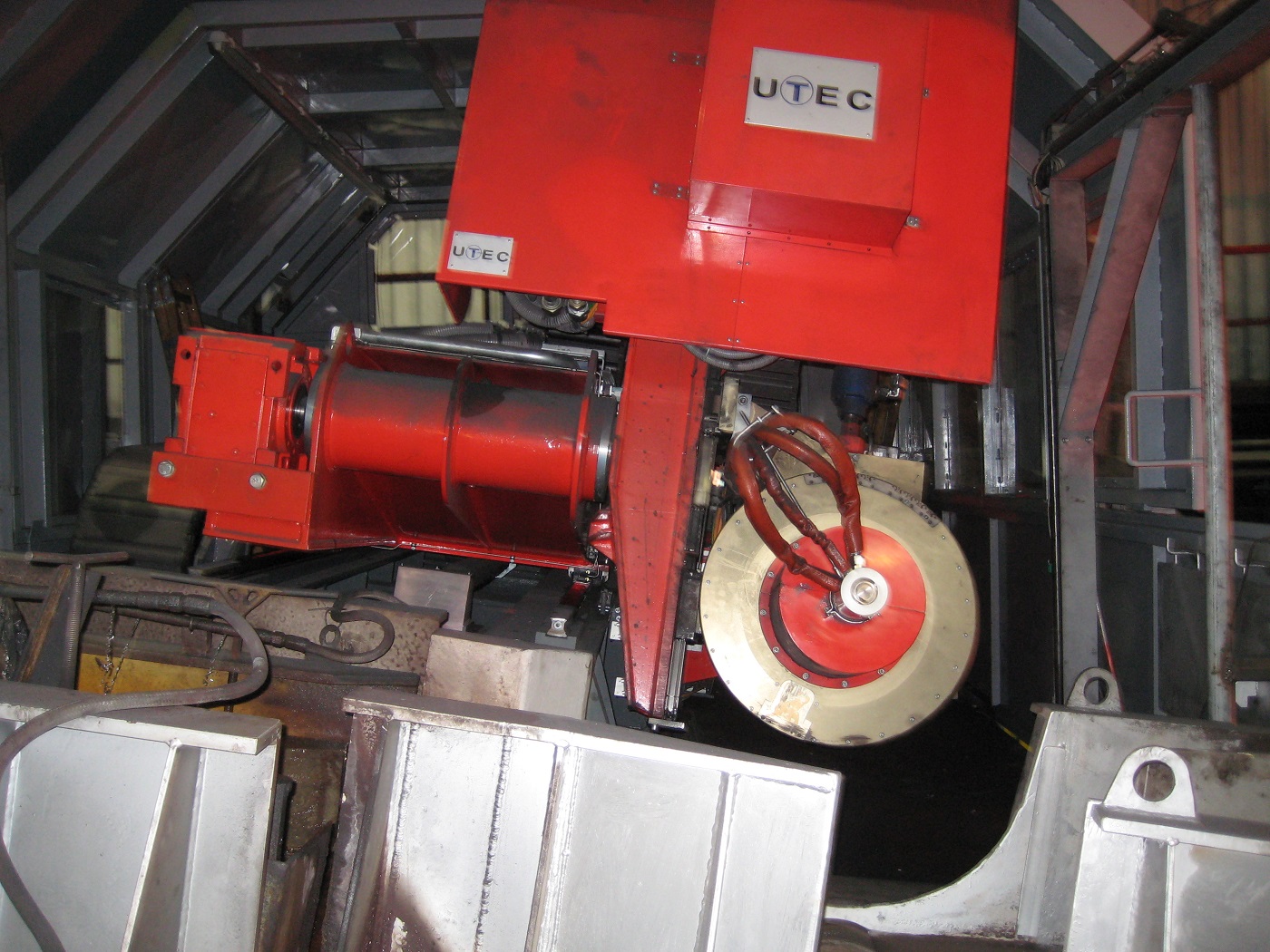

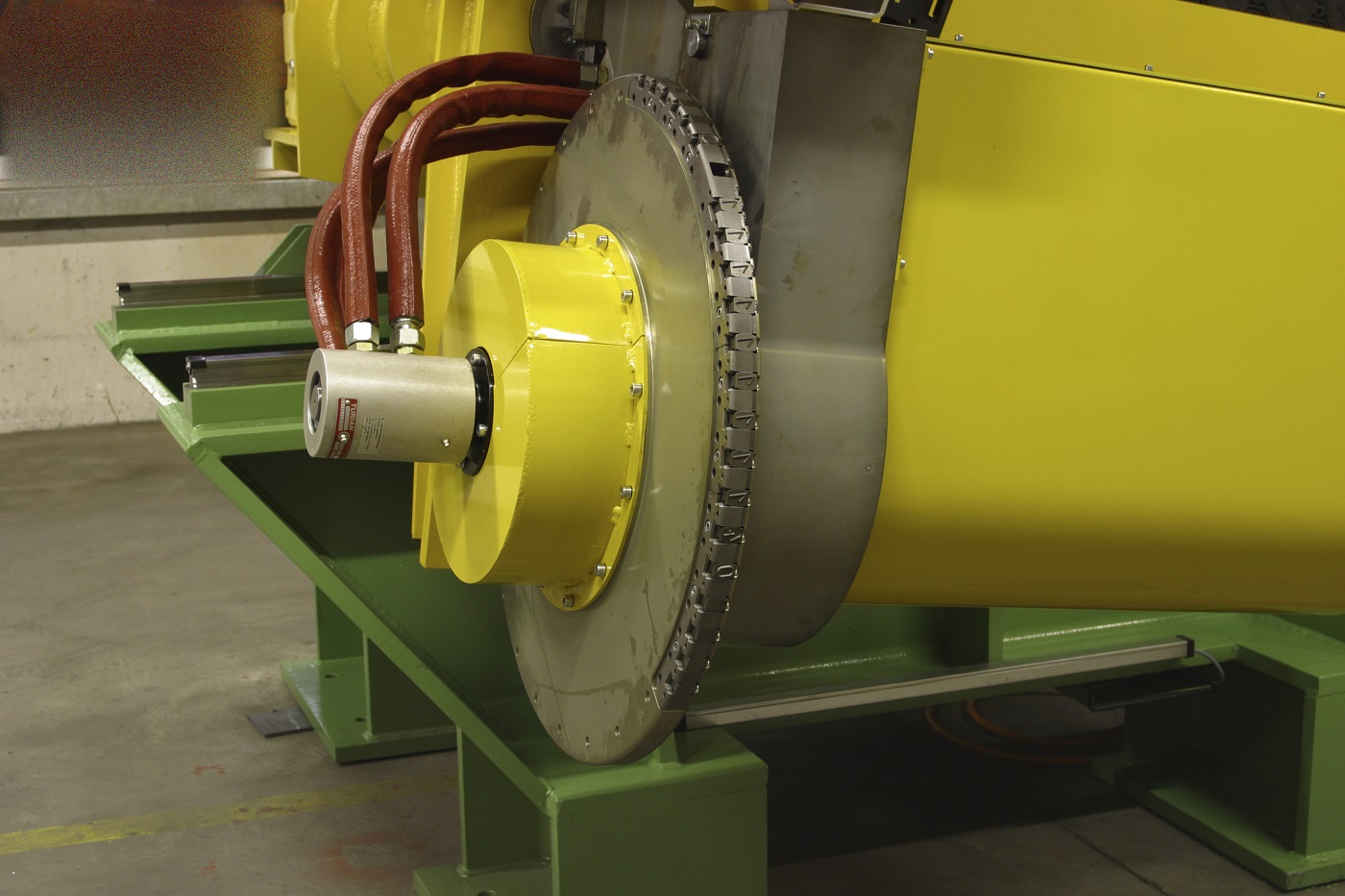

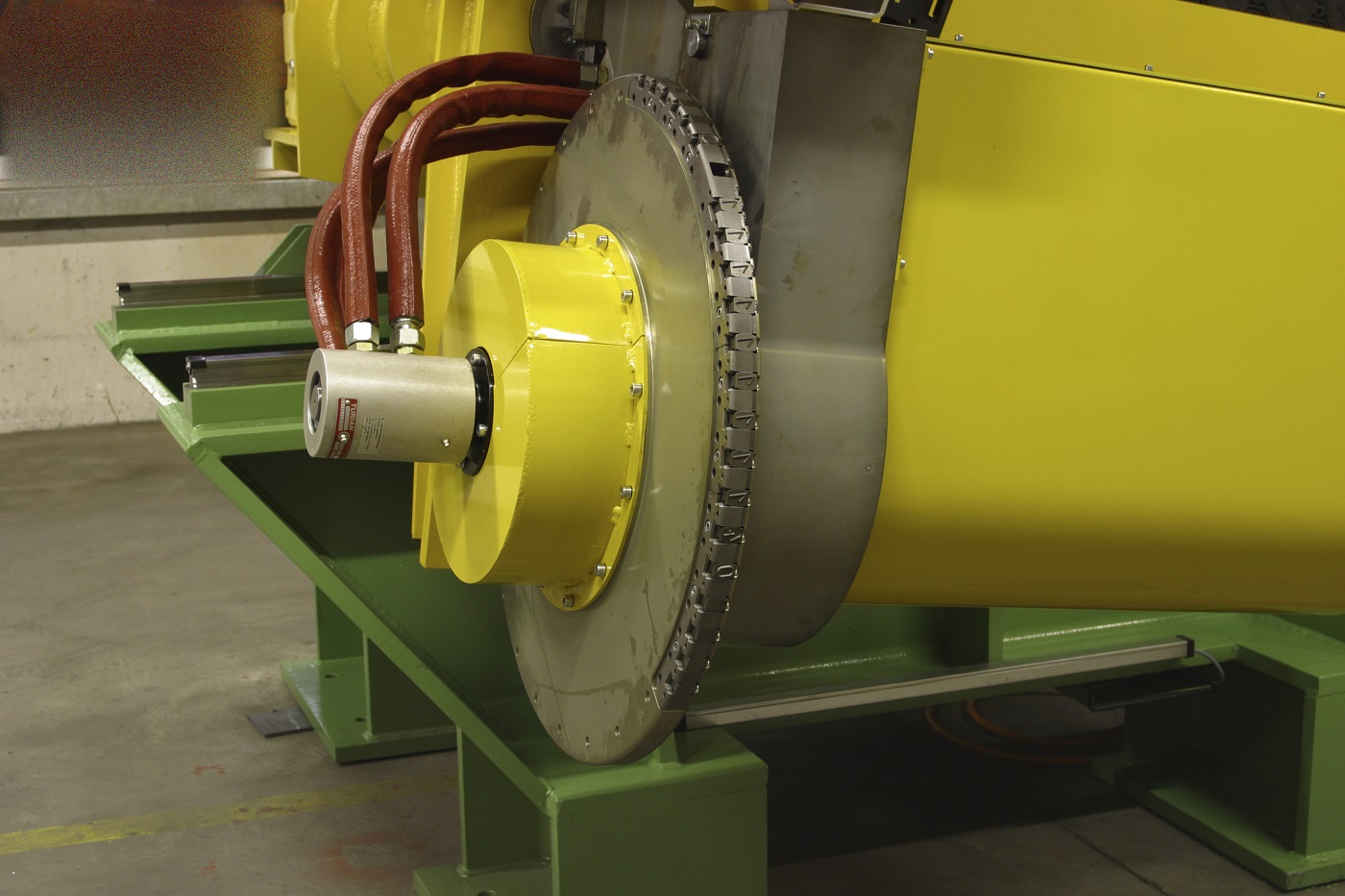

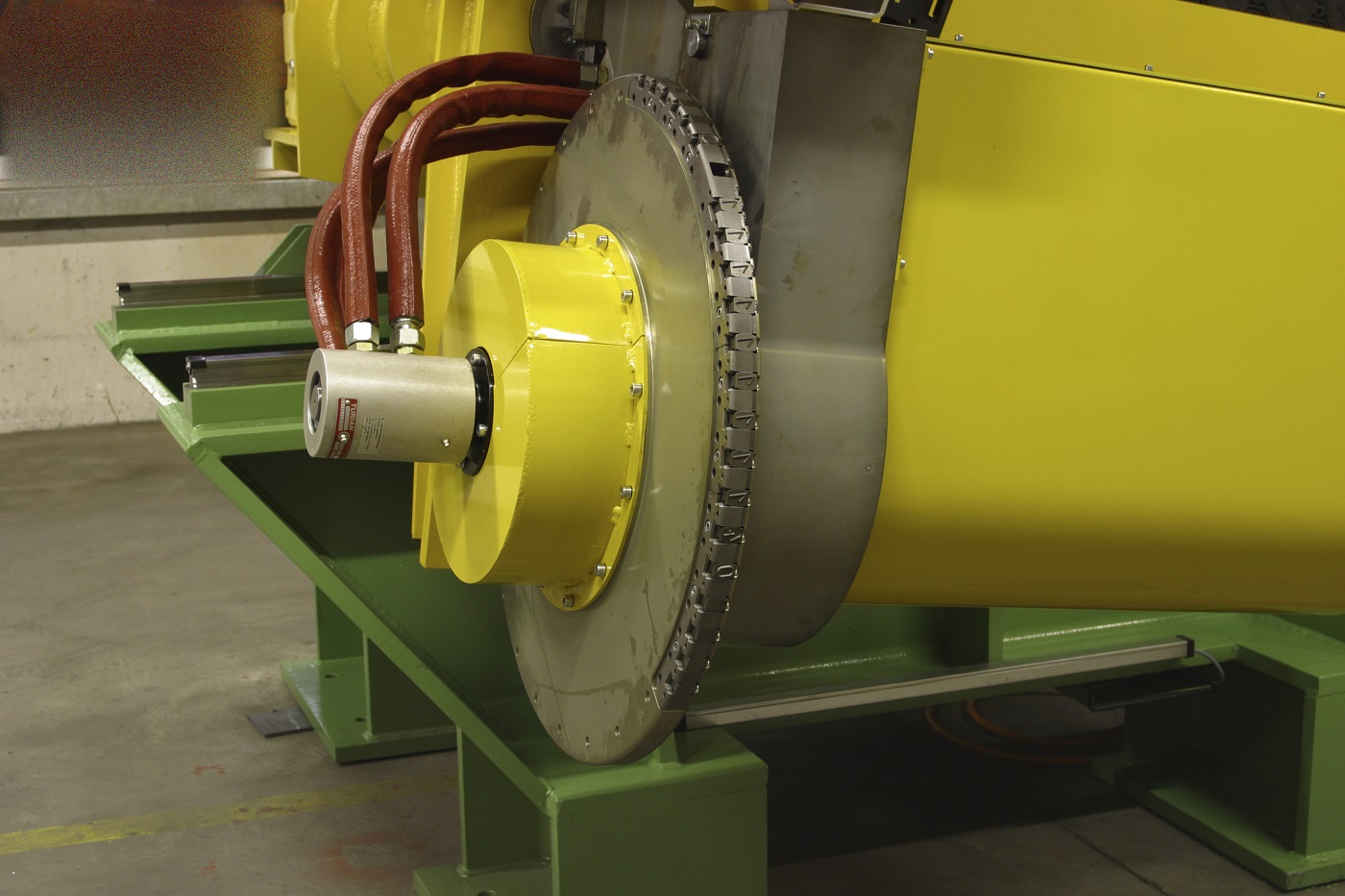

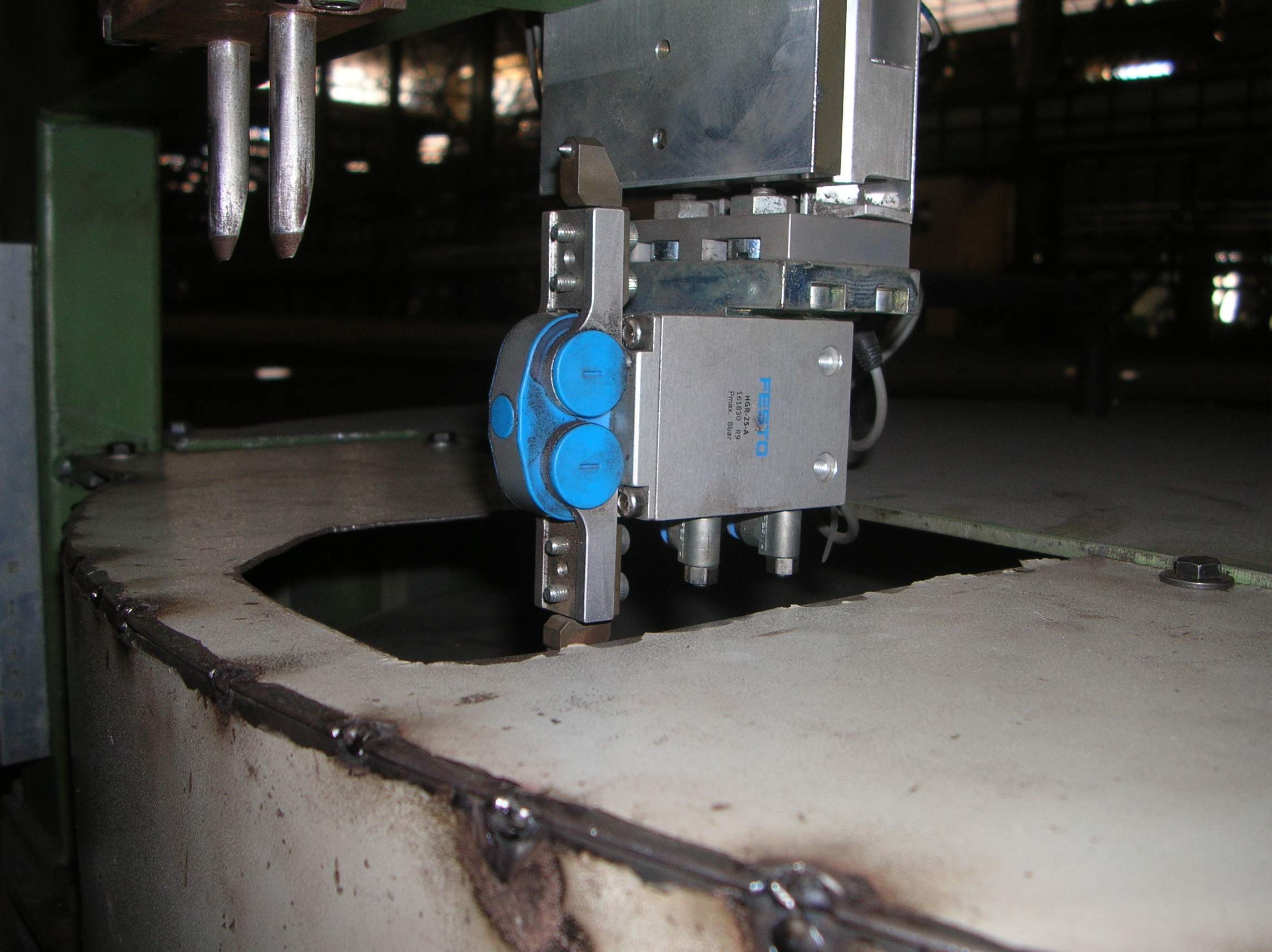

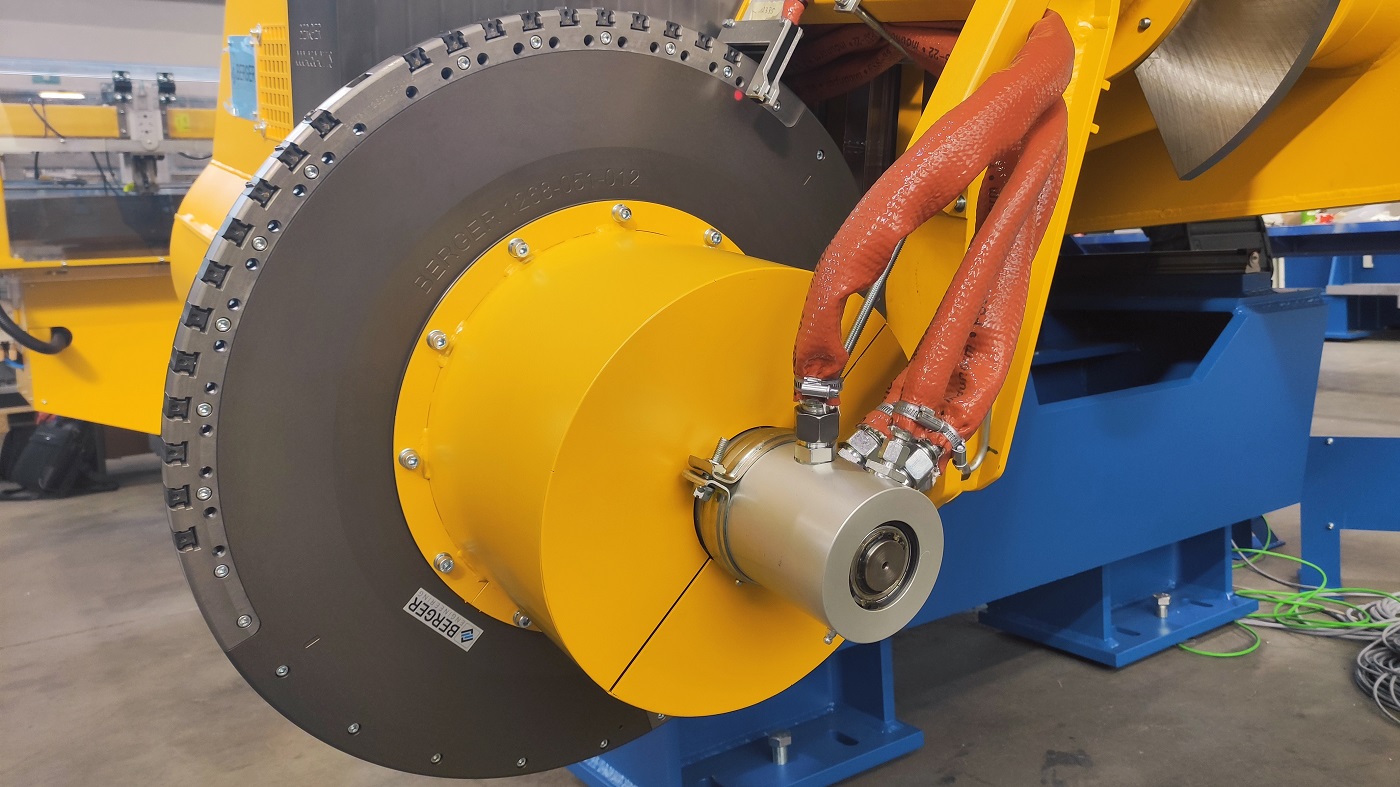

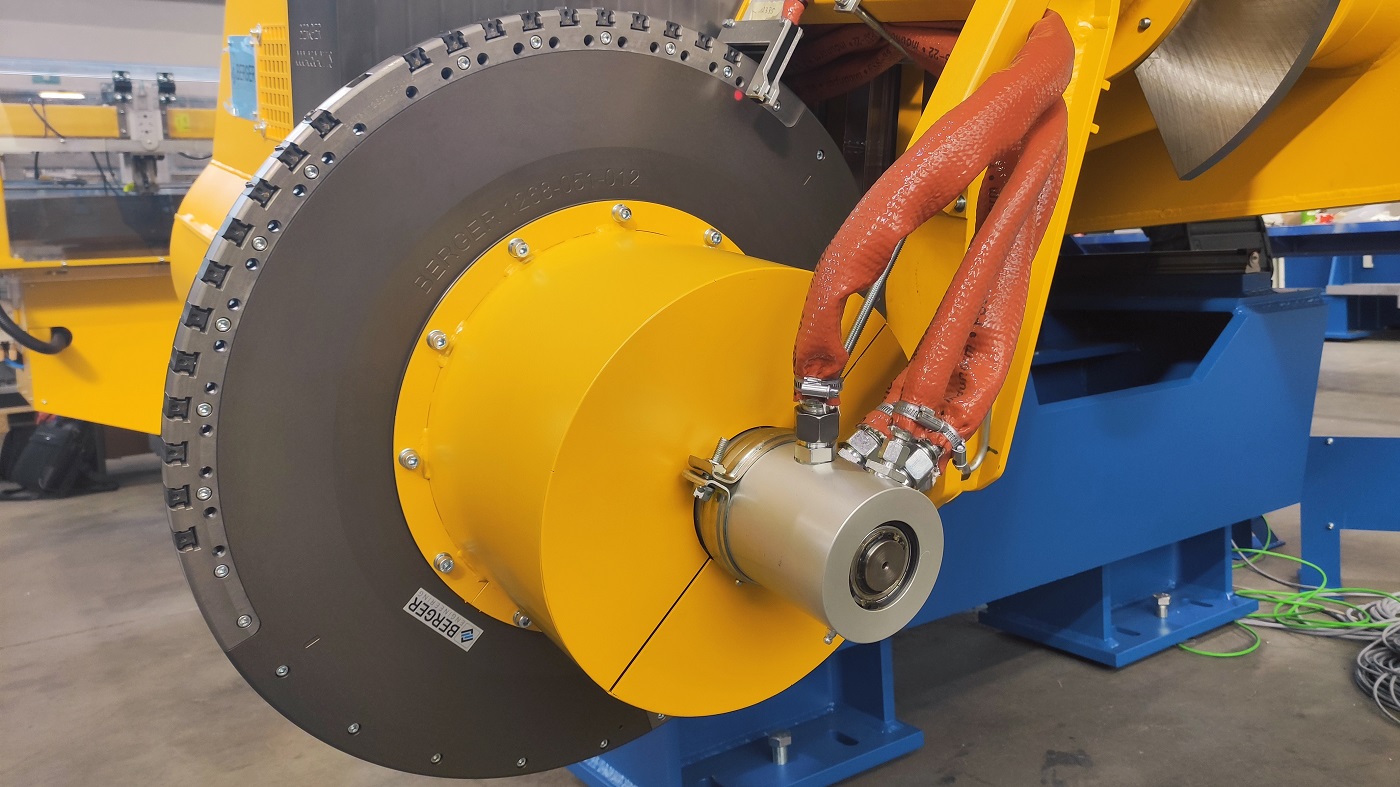

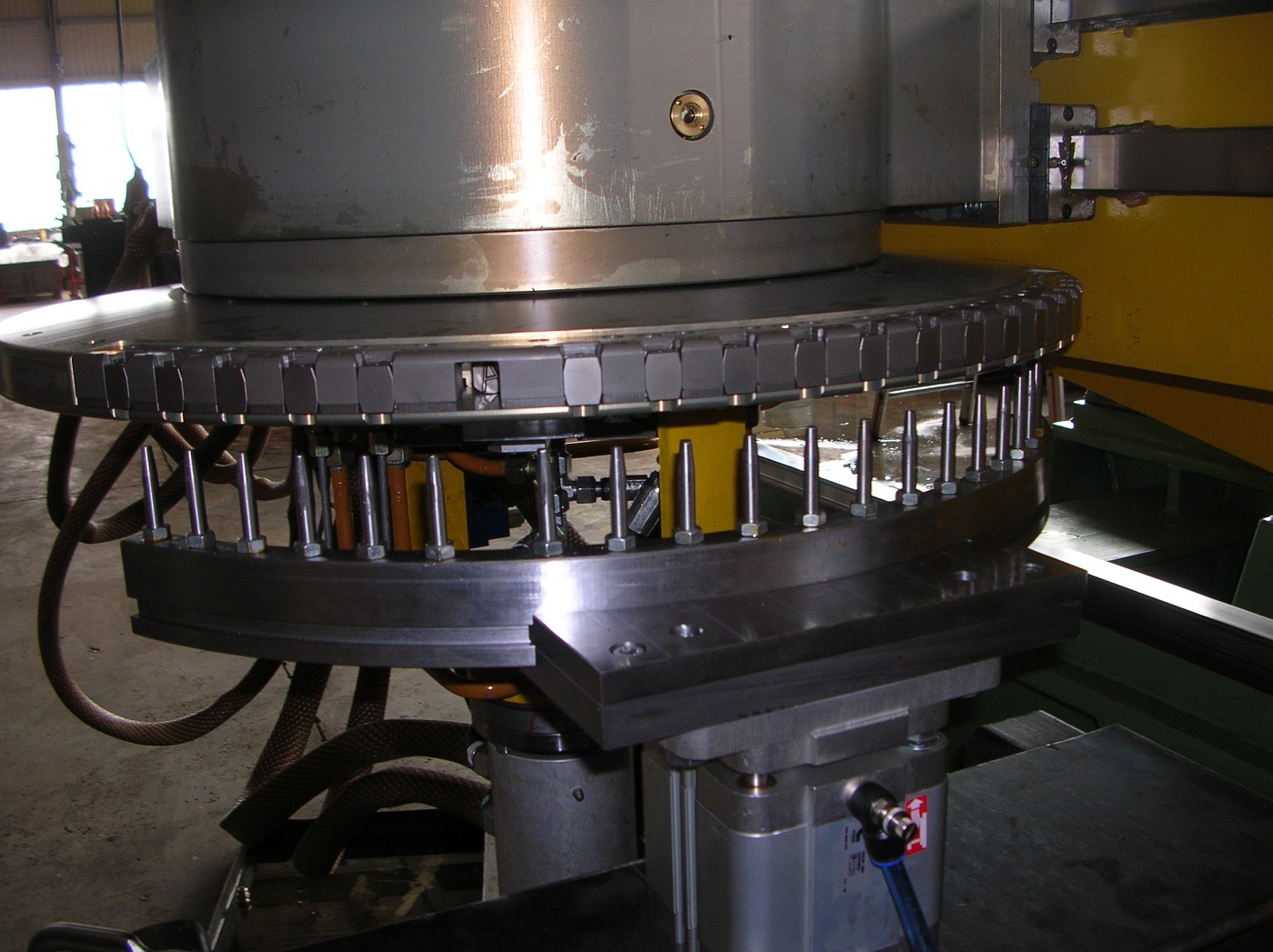

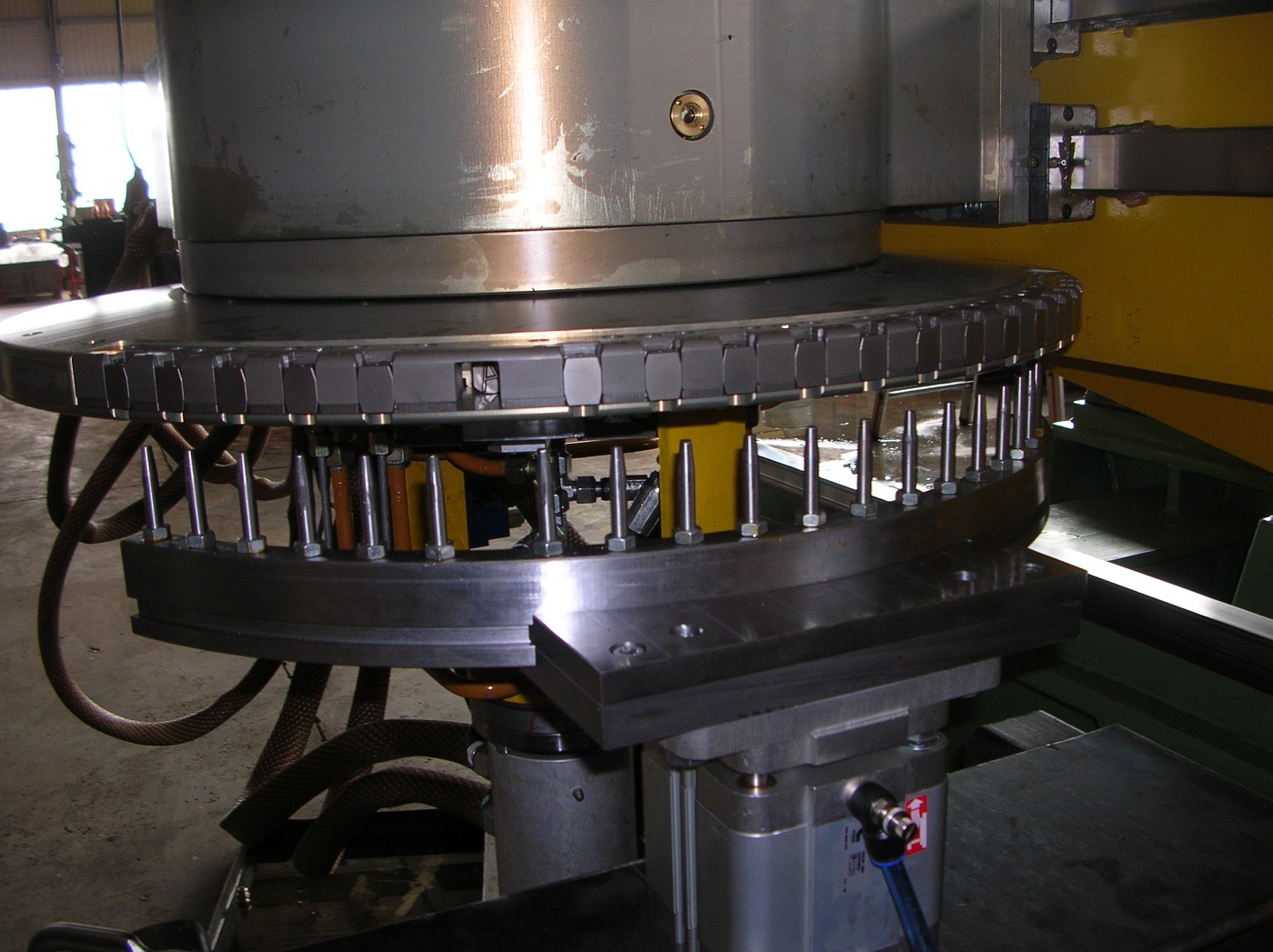

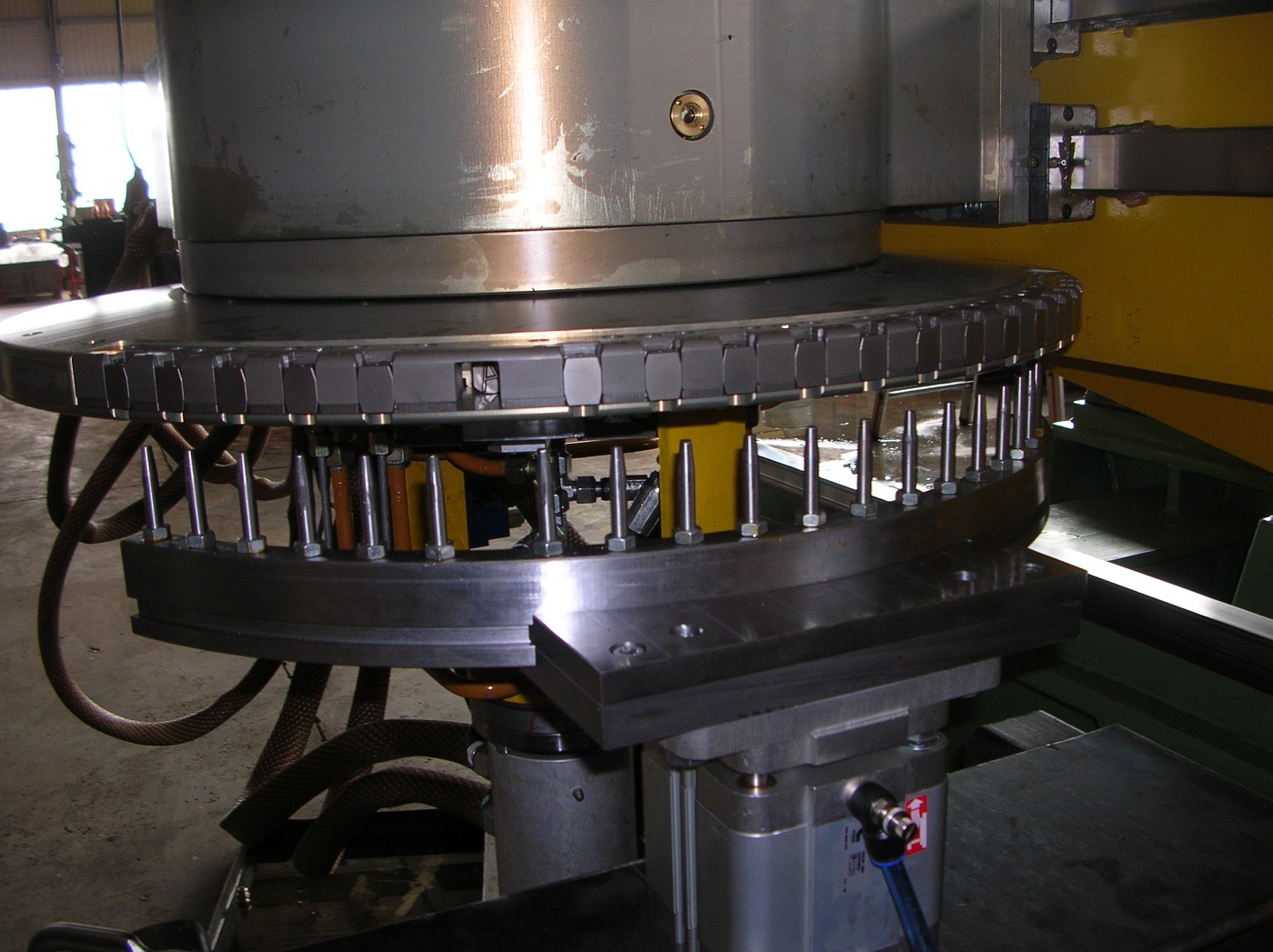

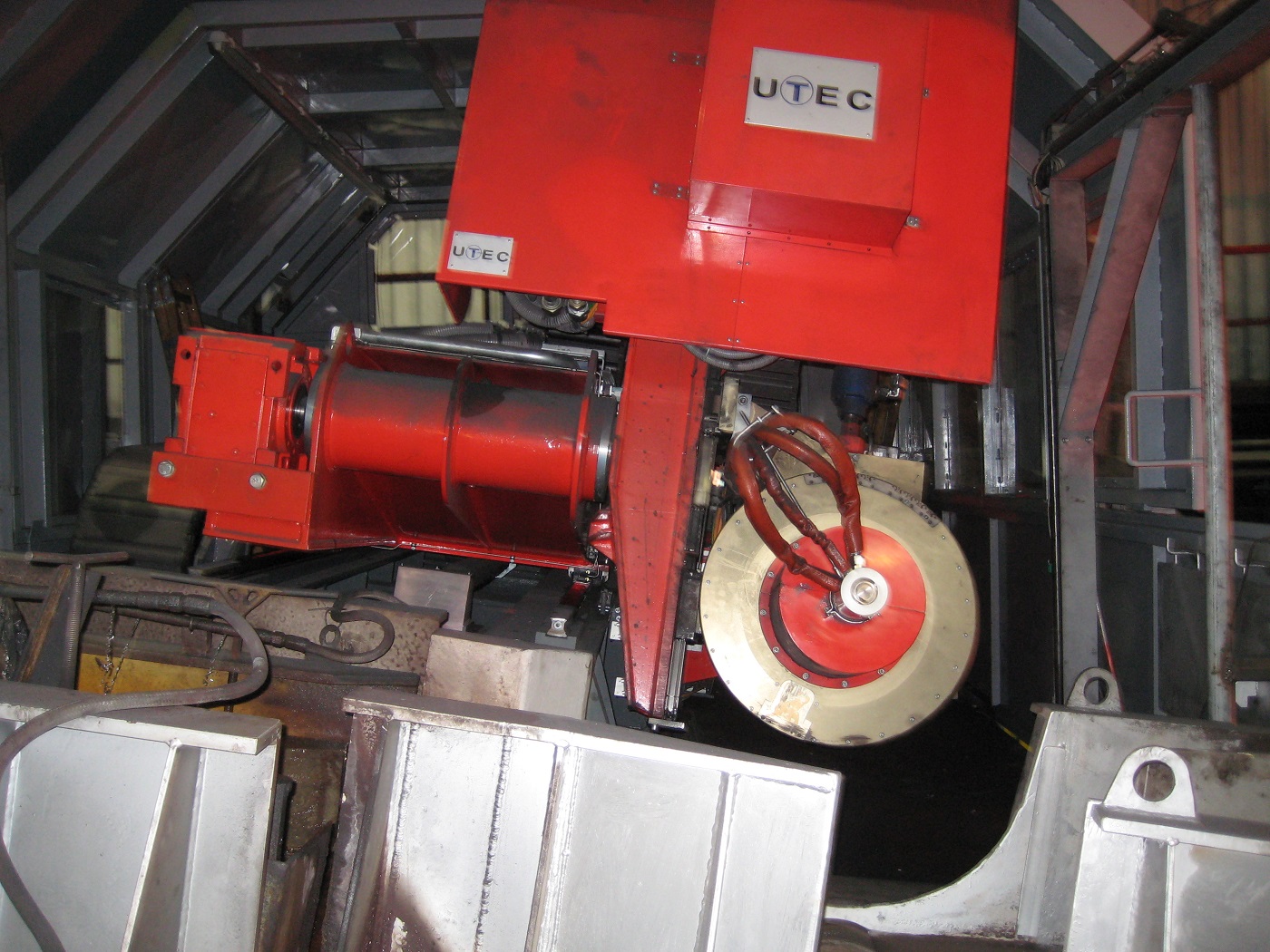

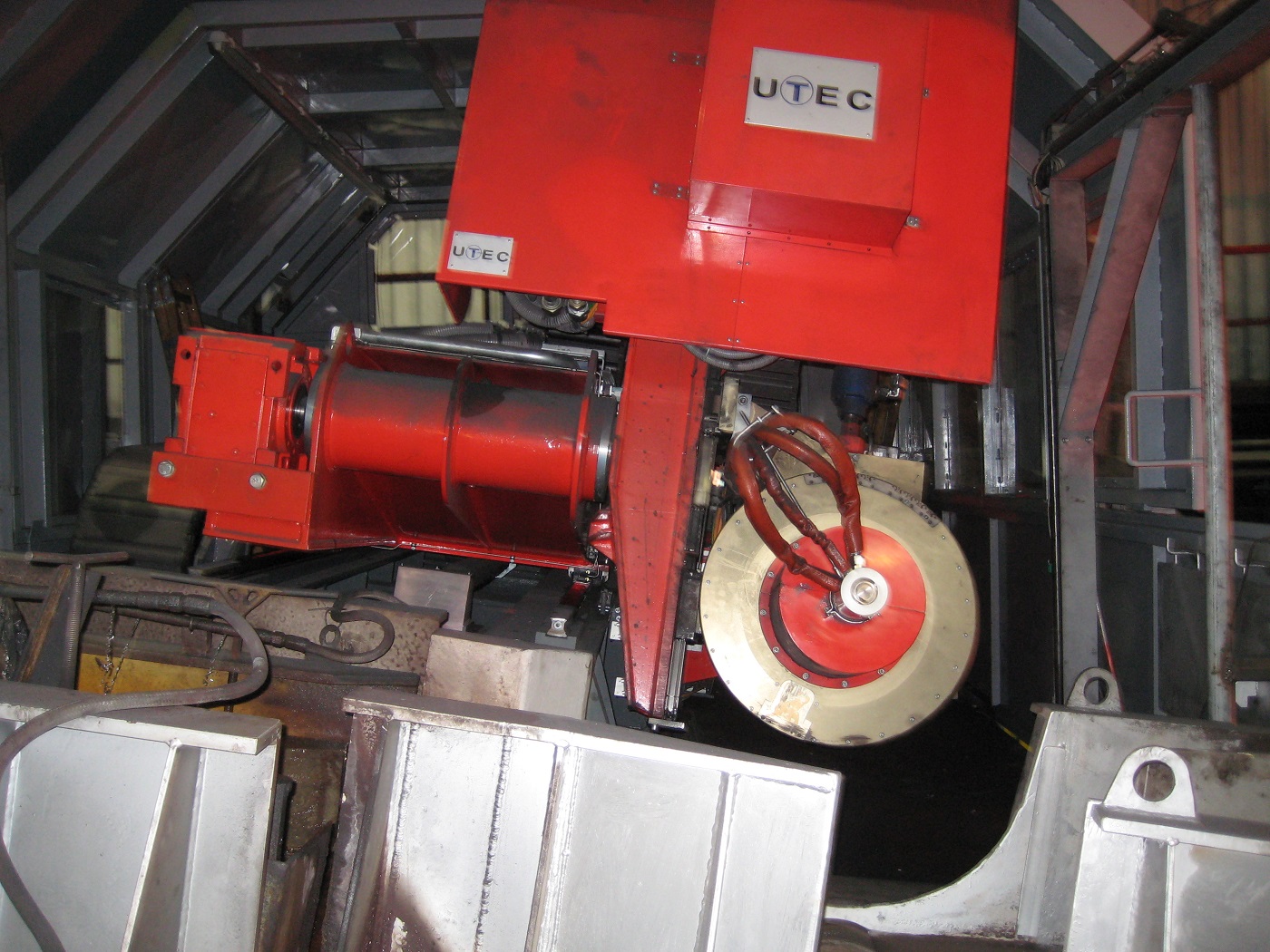

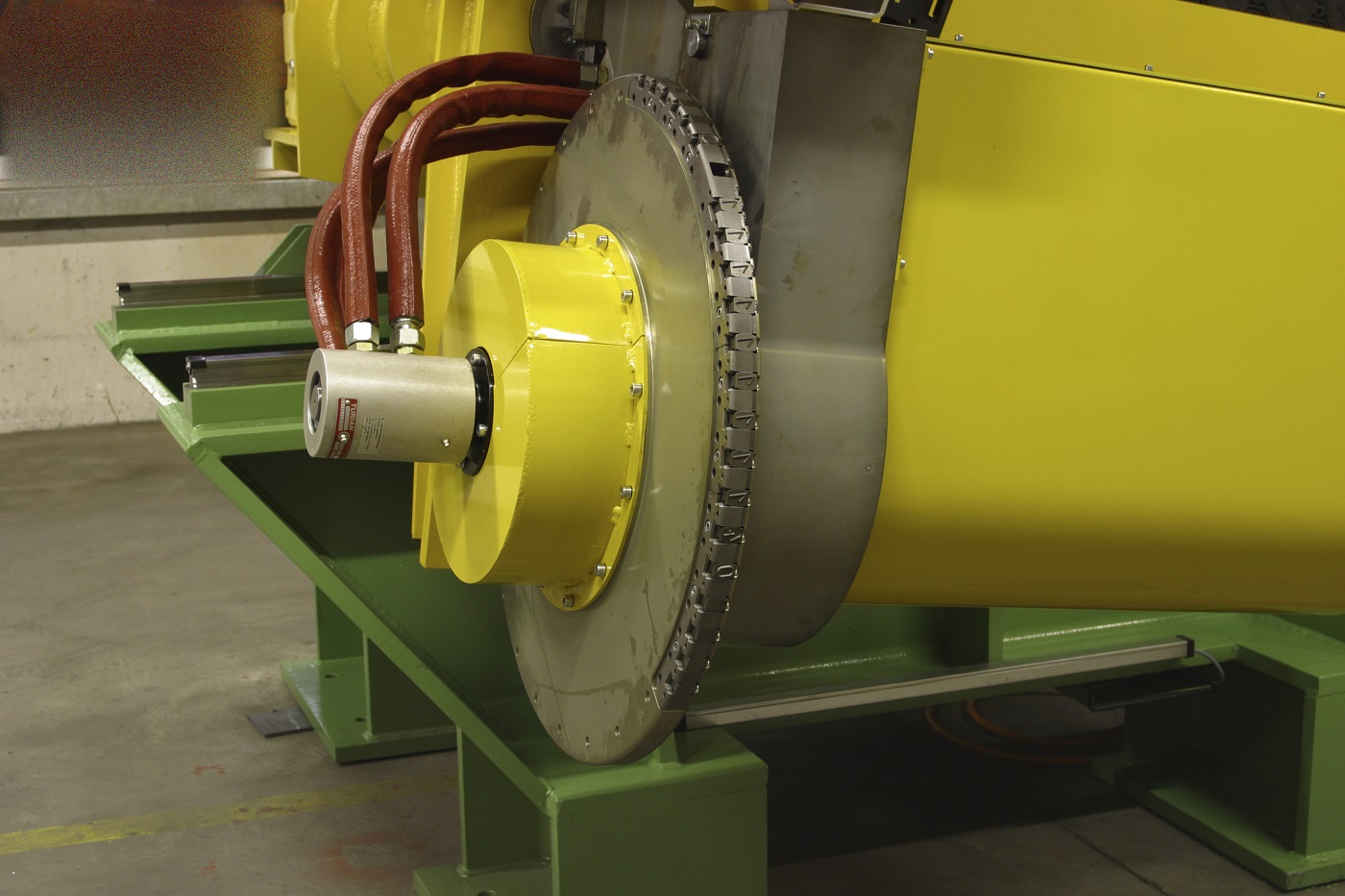

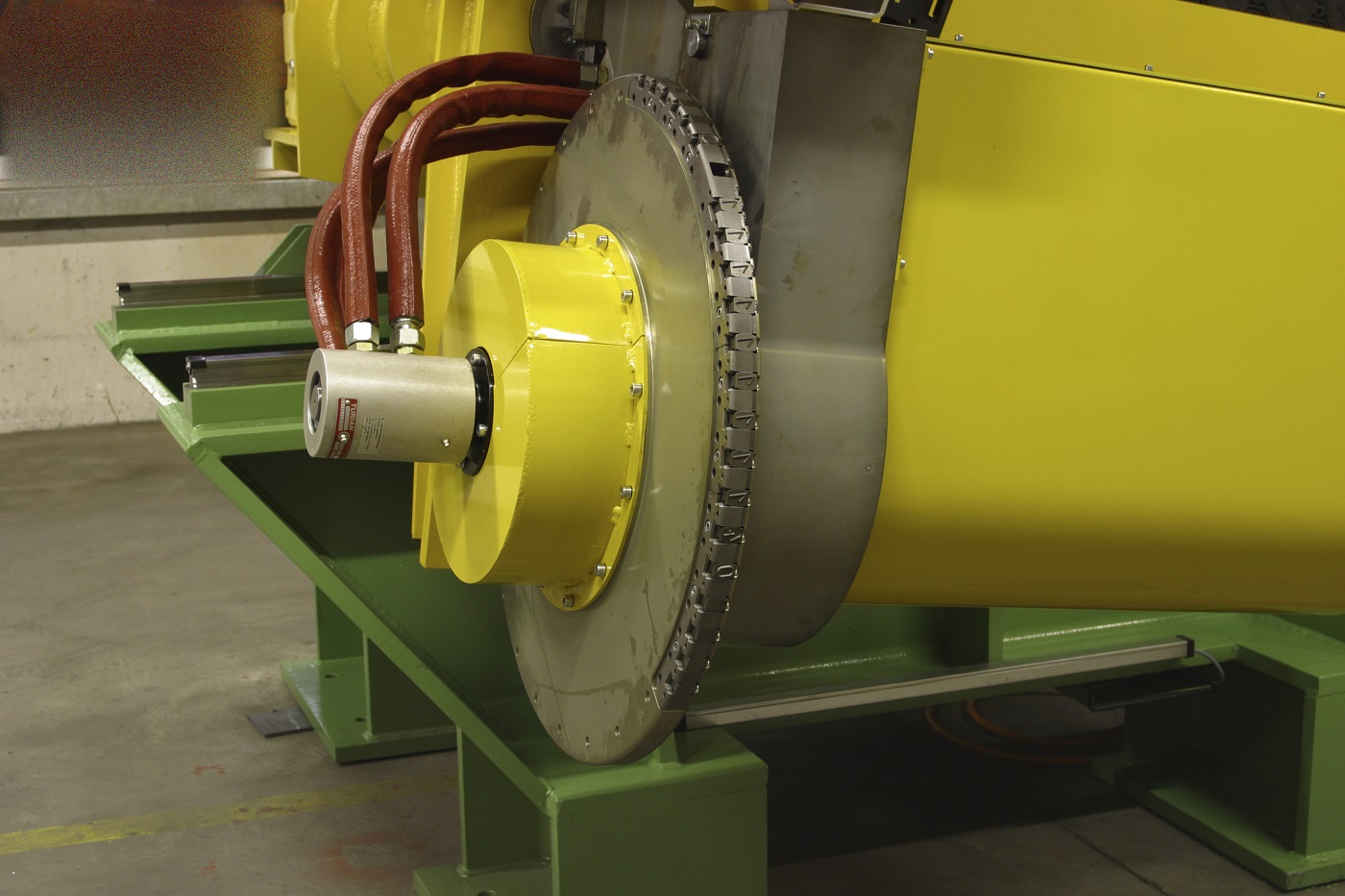

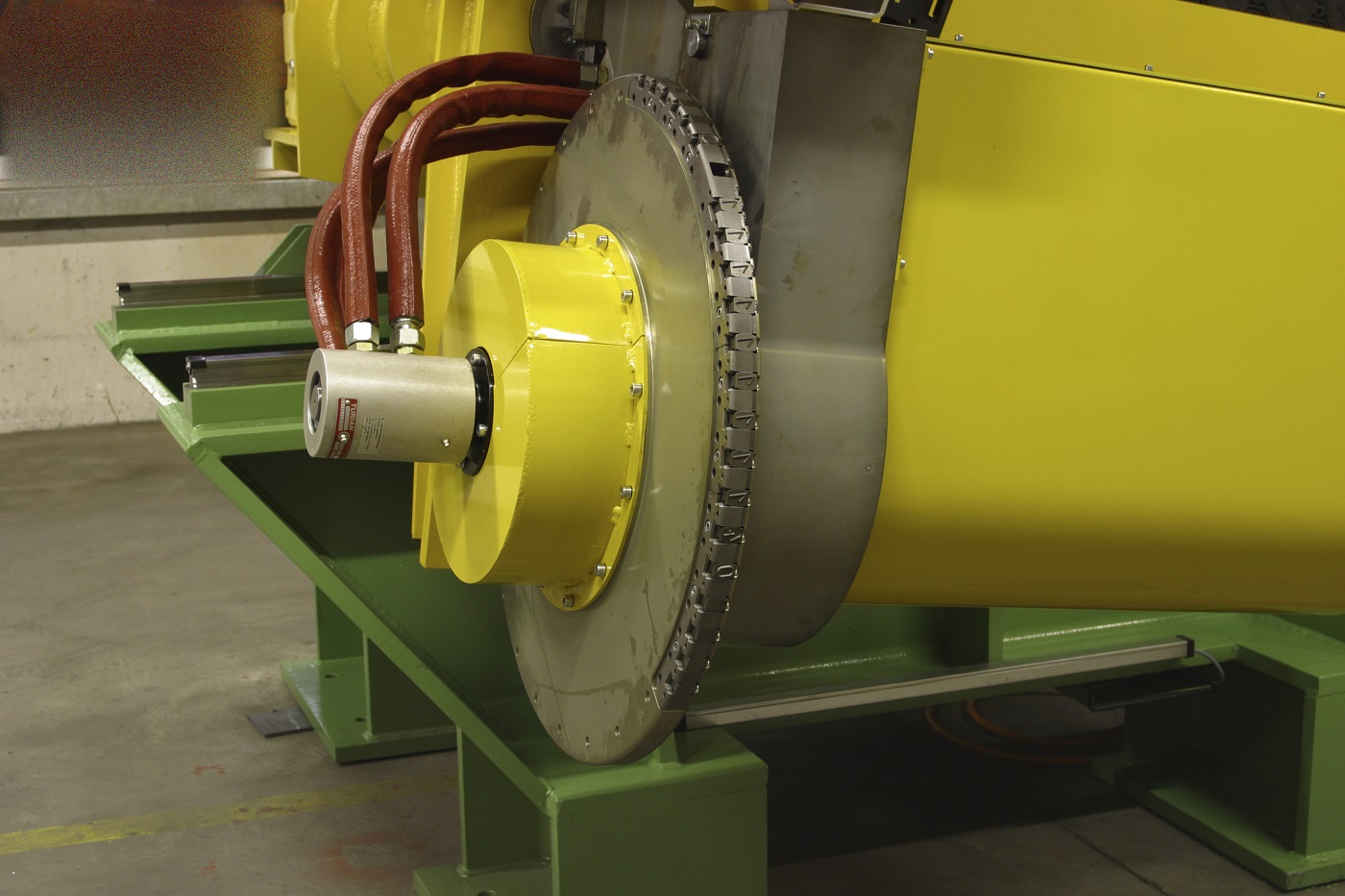

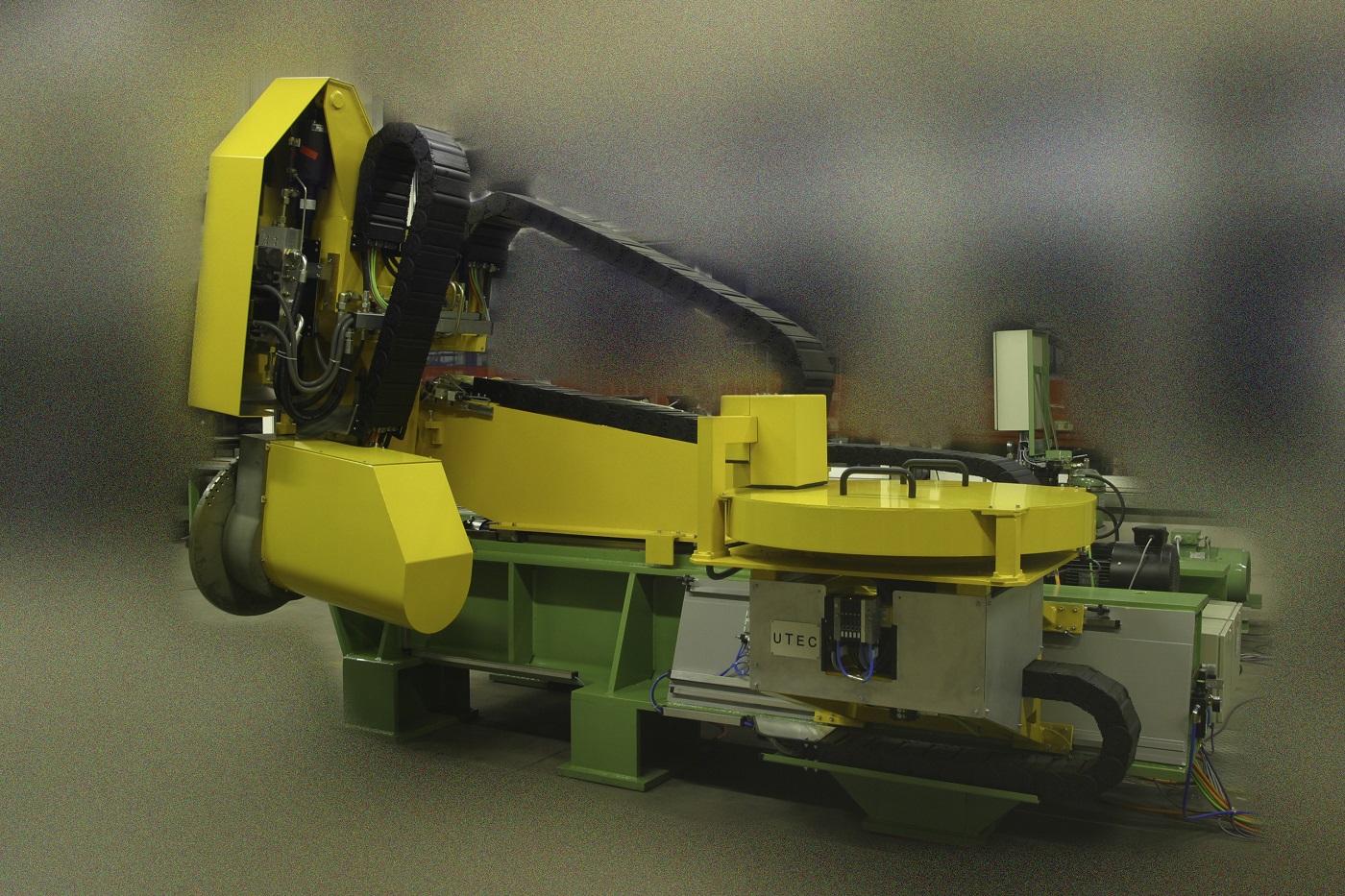

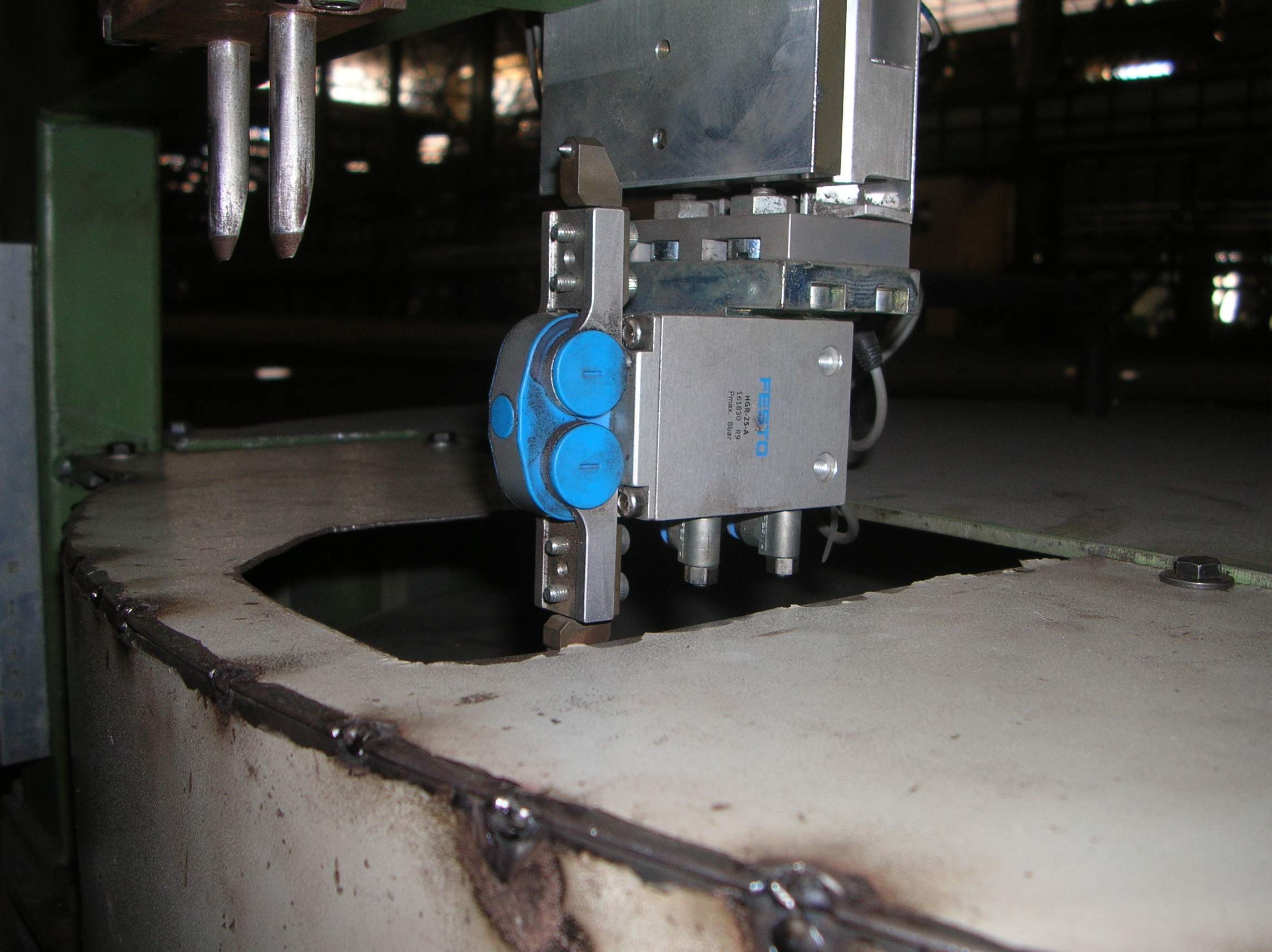

With always new developments like first stamping disc or first magazine disc for rail stamping machines with robotics in change of characters we succeeded to get the awards from the state owned railway companies.

We are inventor for continuously rail stamping with continuously change of characters, which you can see in European and US Patents!

In almost all countries our rail stamping machine is installed and those rail stamping machines stamp more than 92% of the world production.

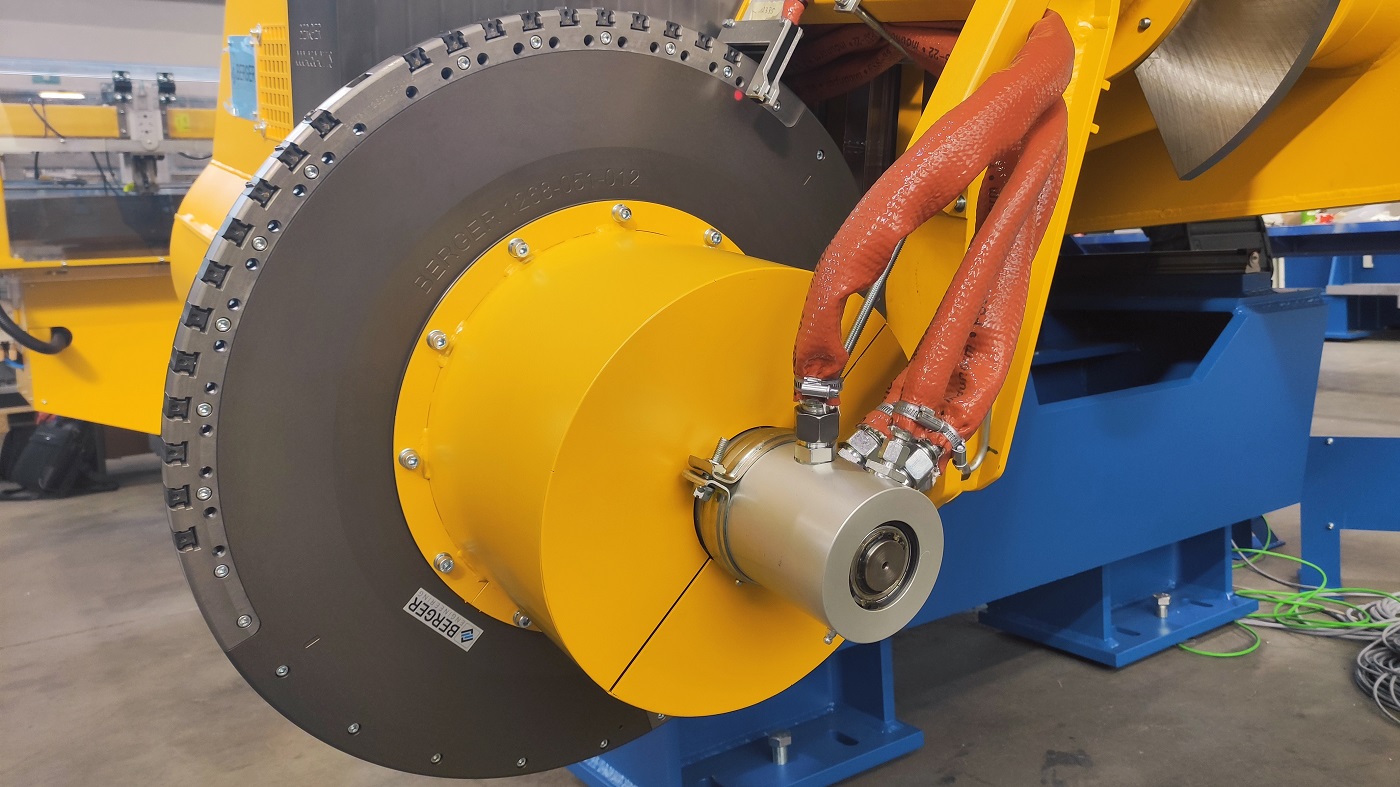

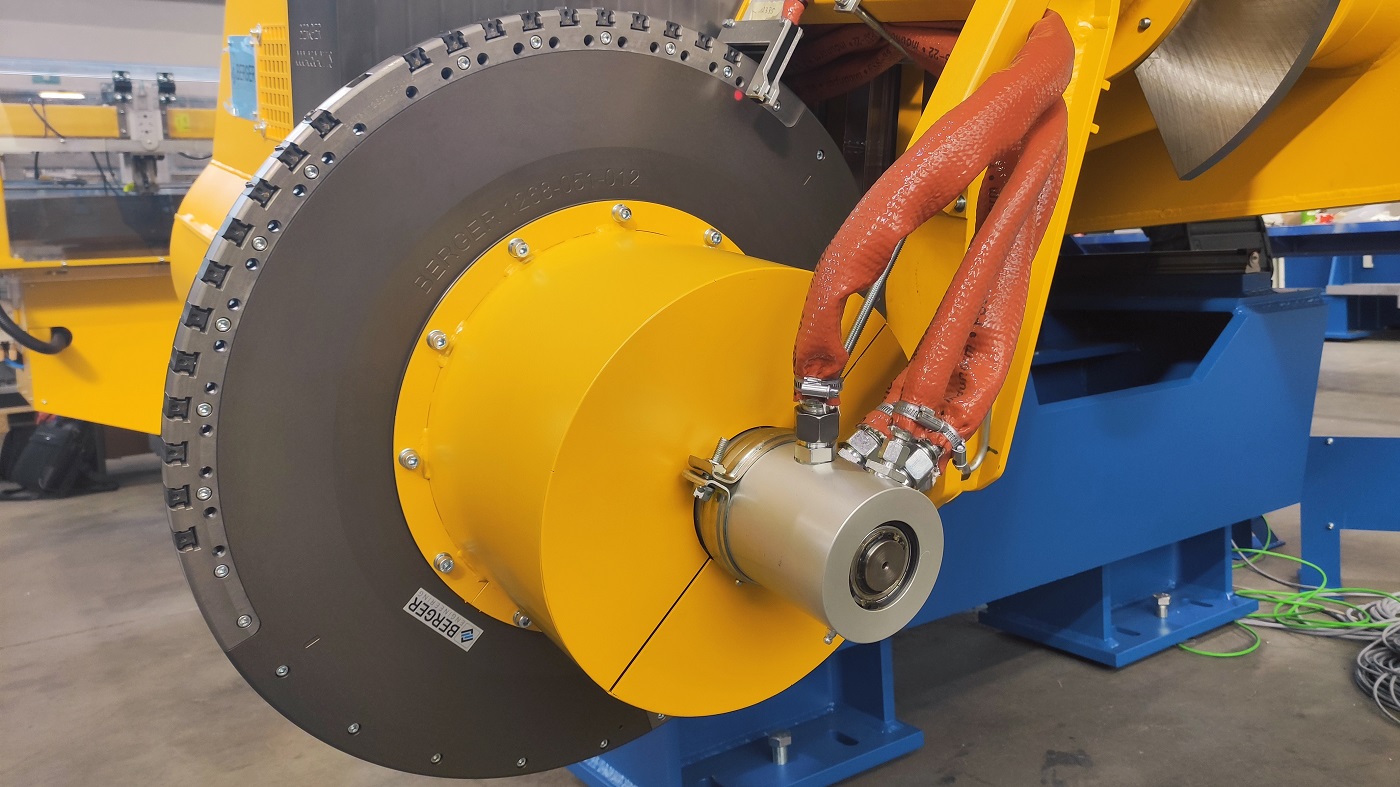

Parameter

BERGER STANDARDS FOR RAIL STAMPING MACHINES:

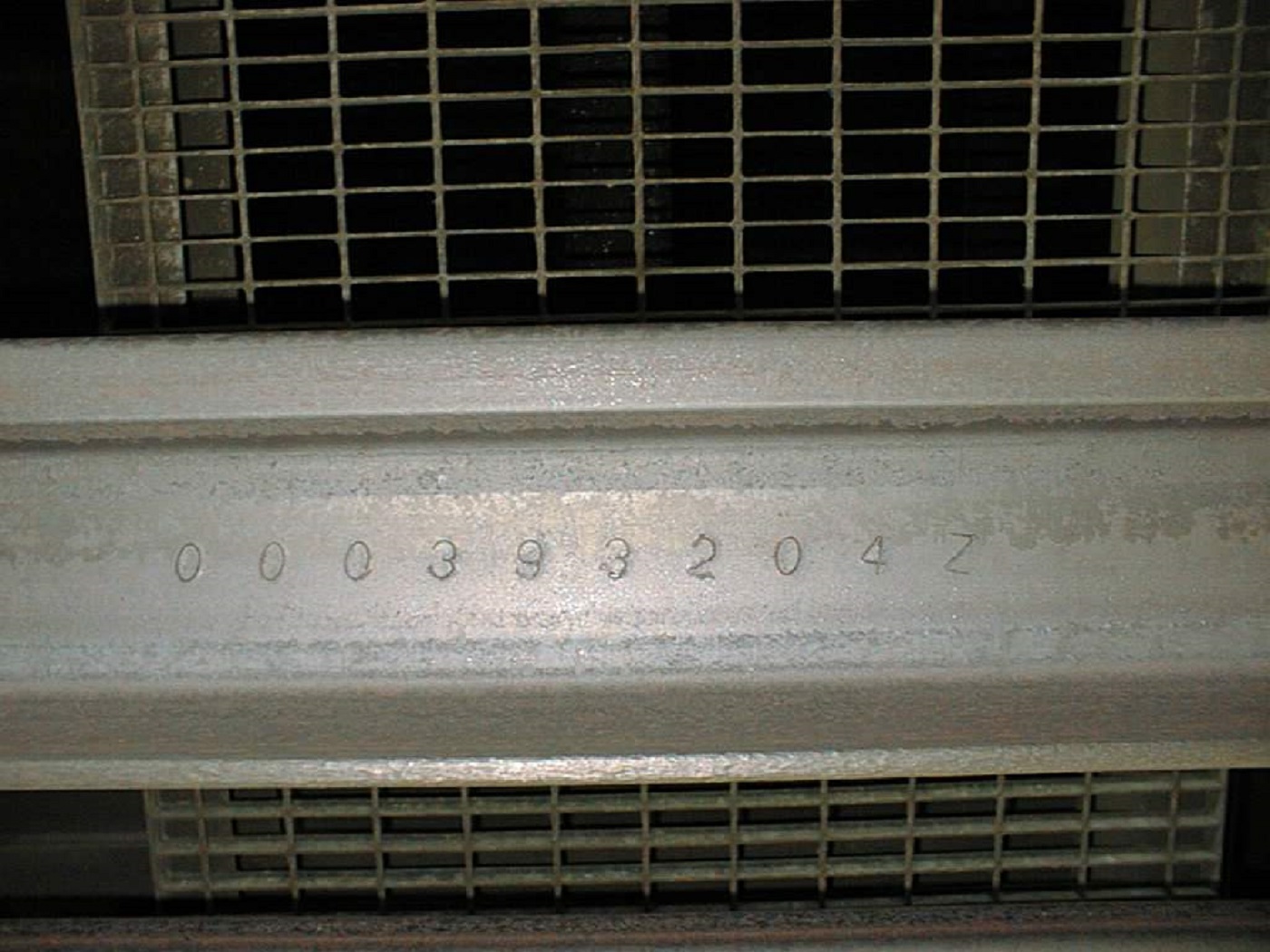

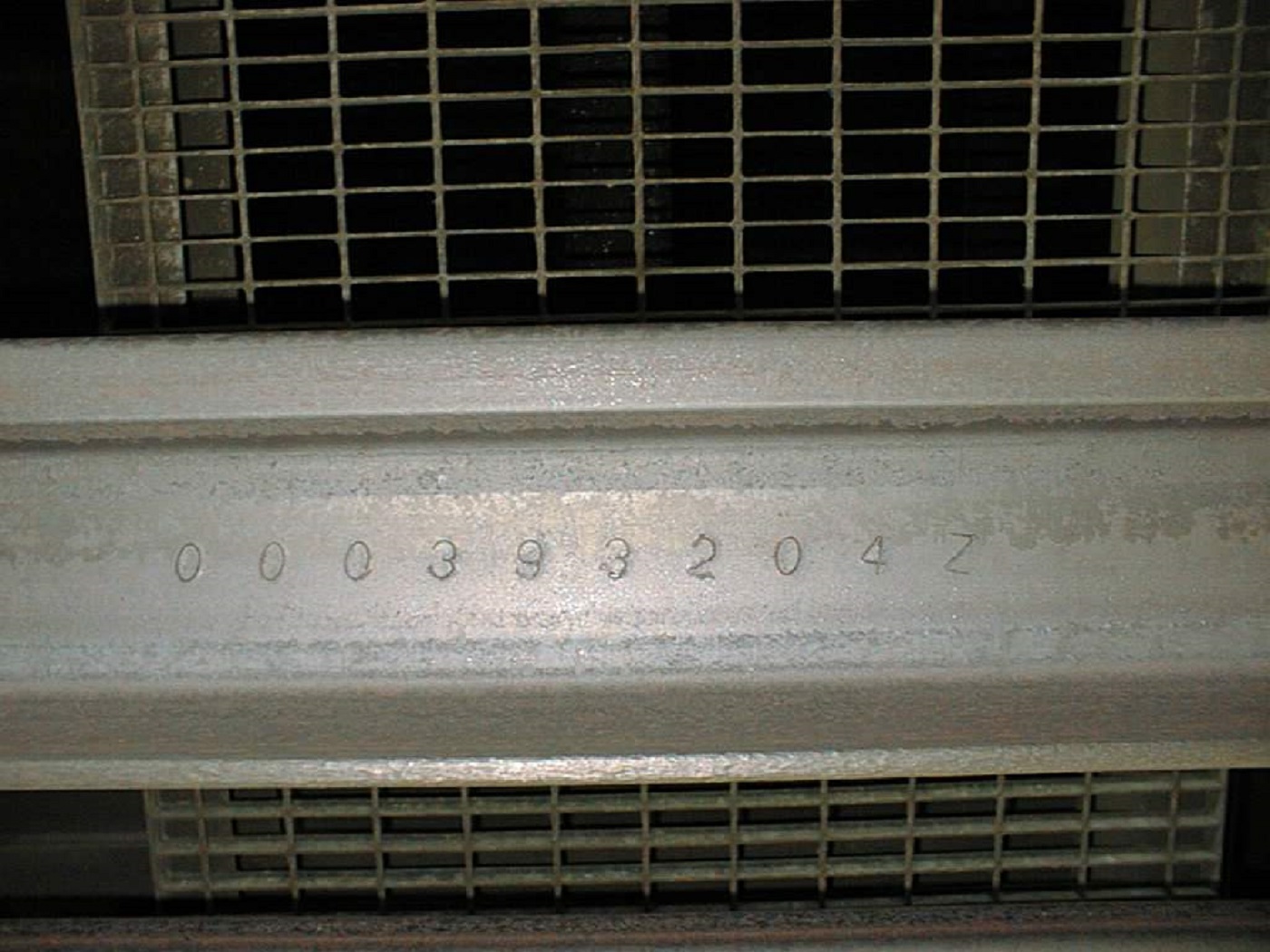

- Highest stamping quality and readability of rail stamping (100%)

- Highest reliability and safety of stamping machines

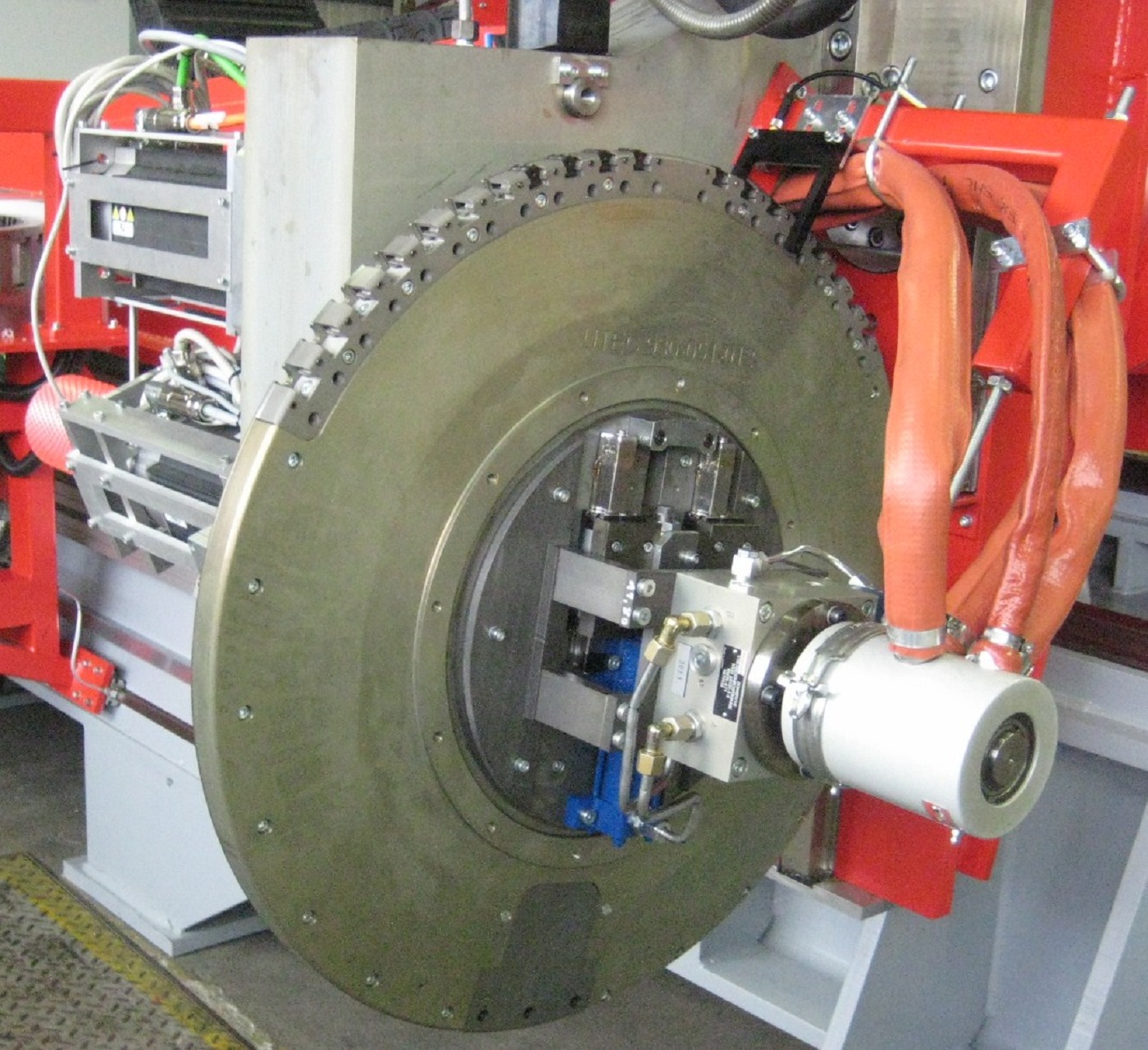

- Shortest maintenance time on changing the stamping disc

- Highest durability

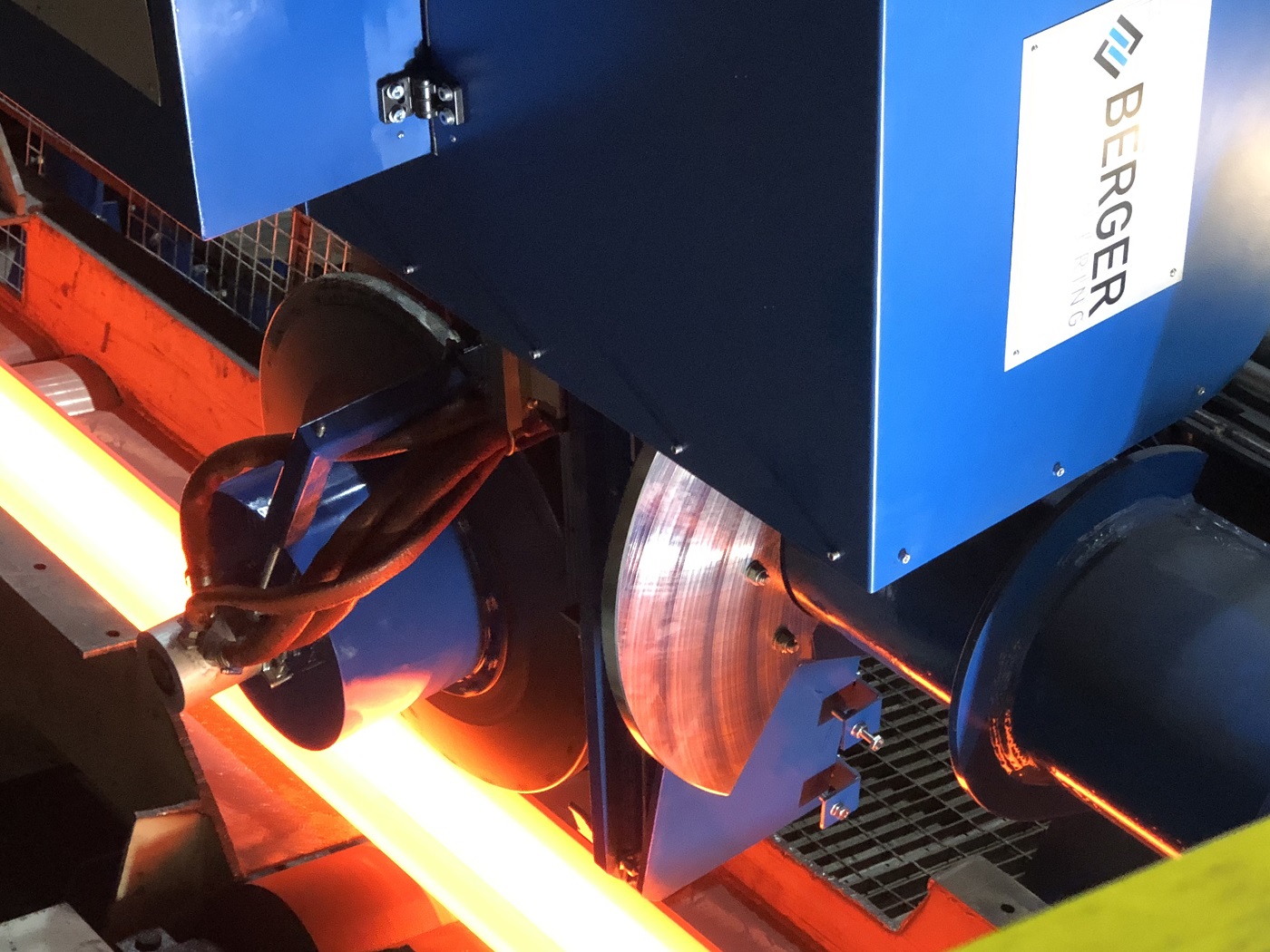

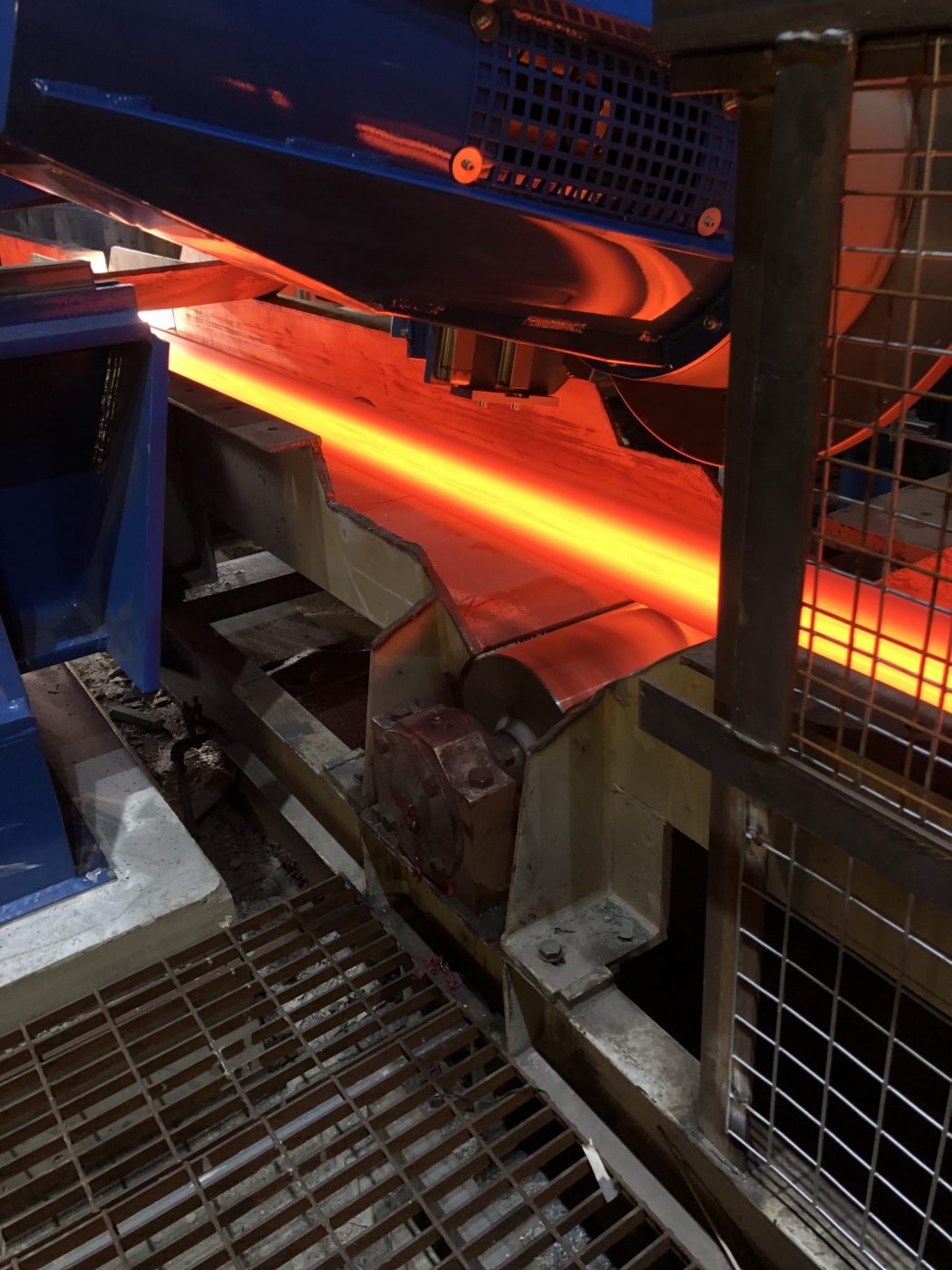

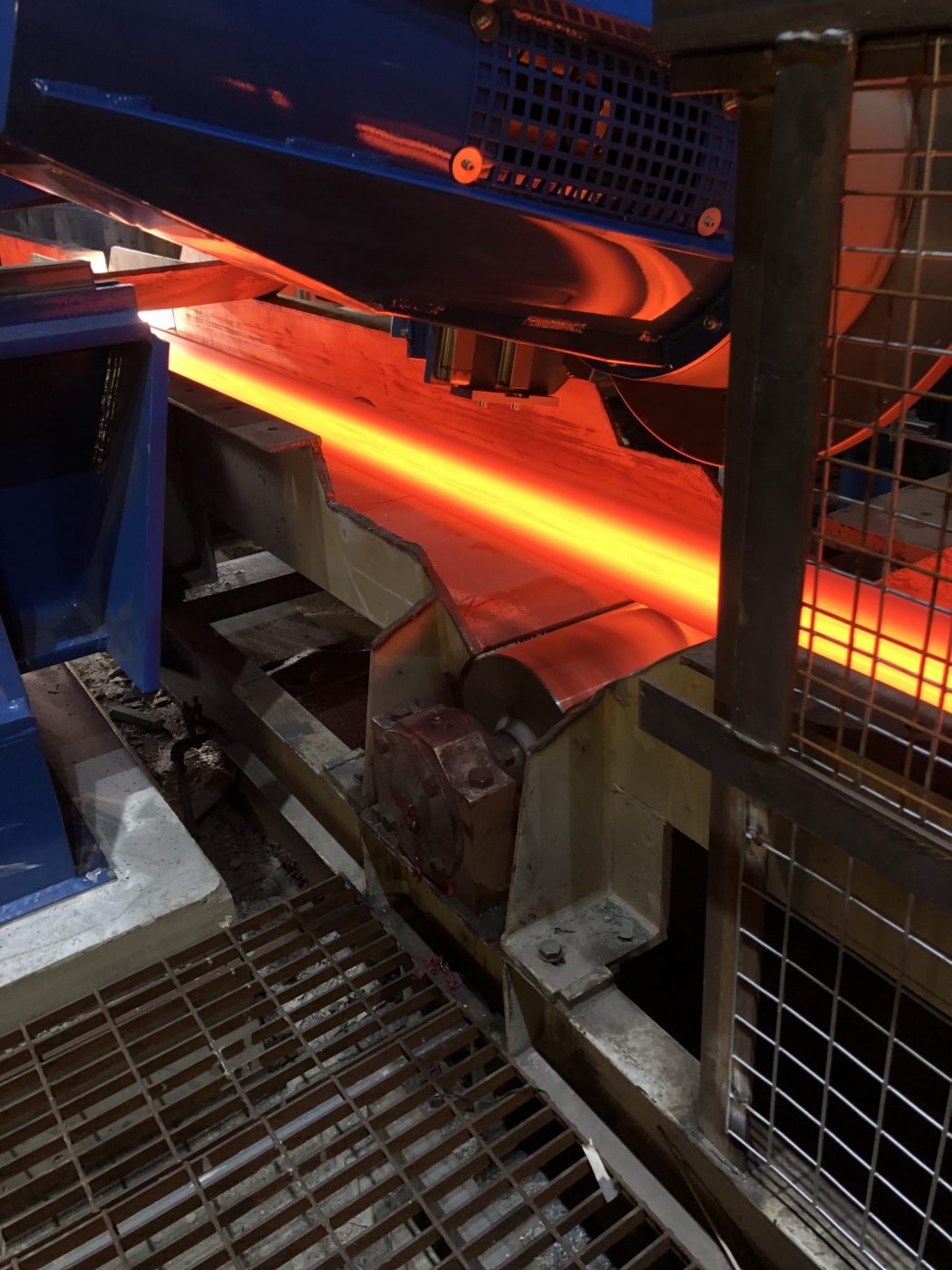

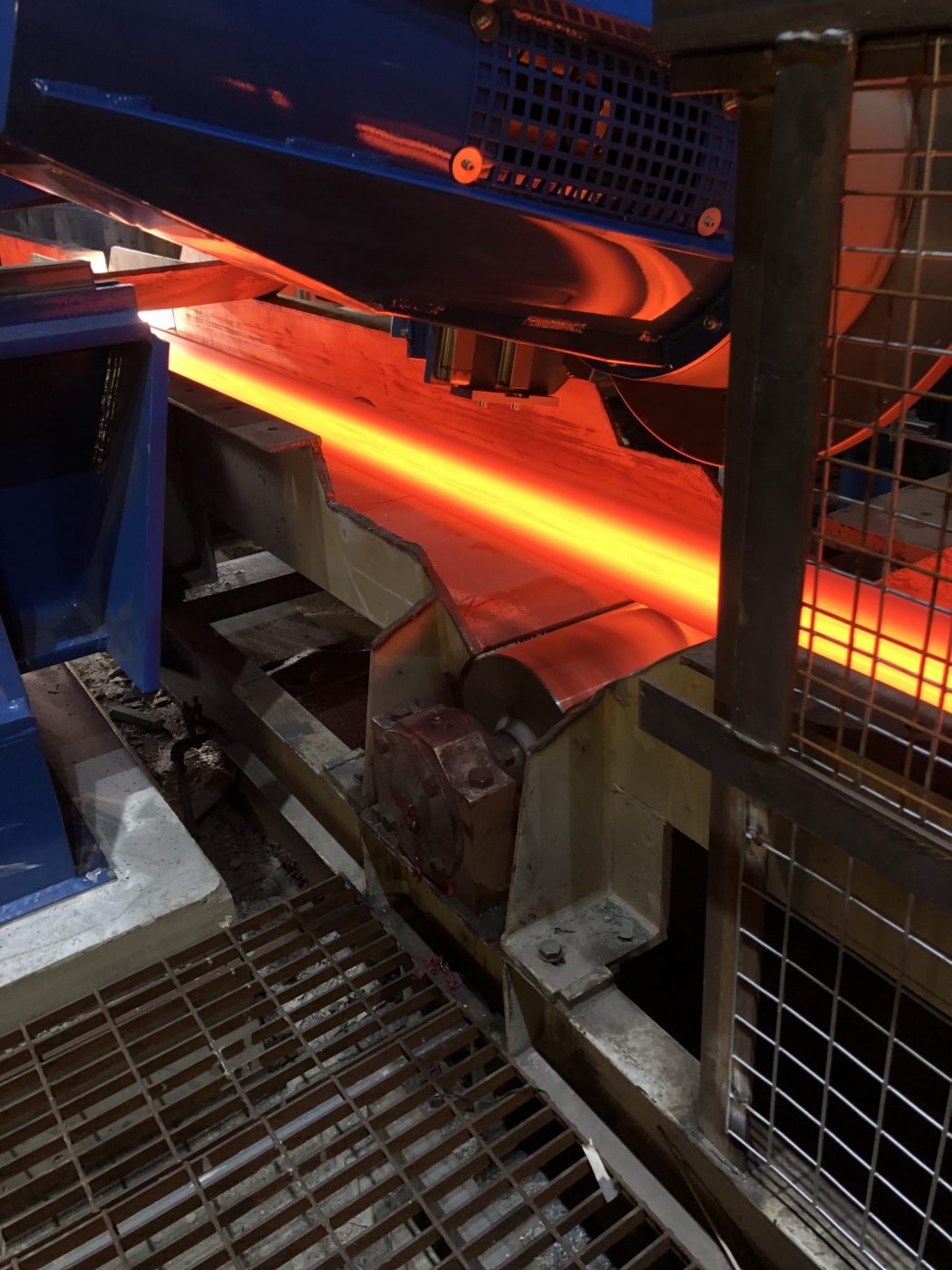

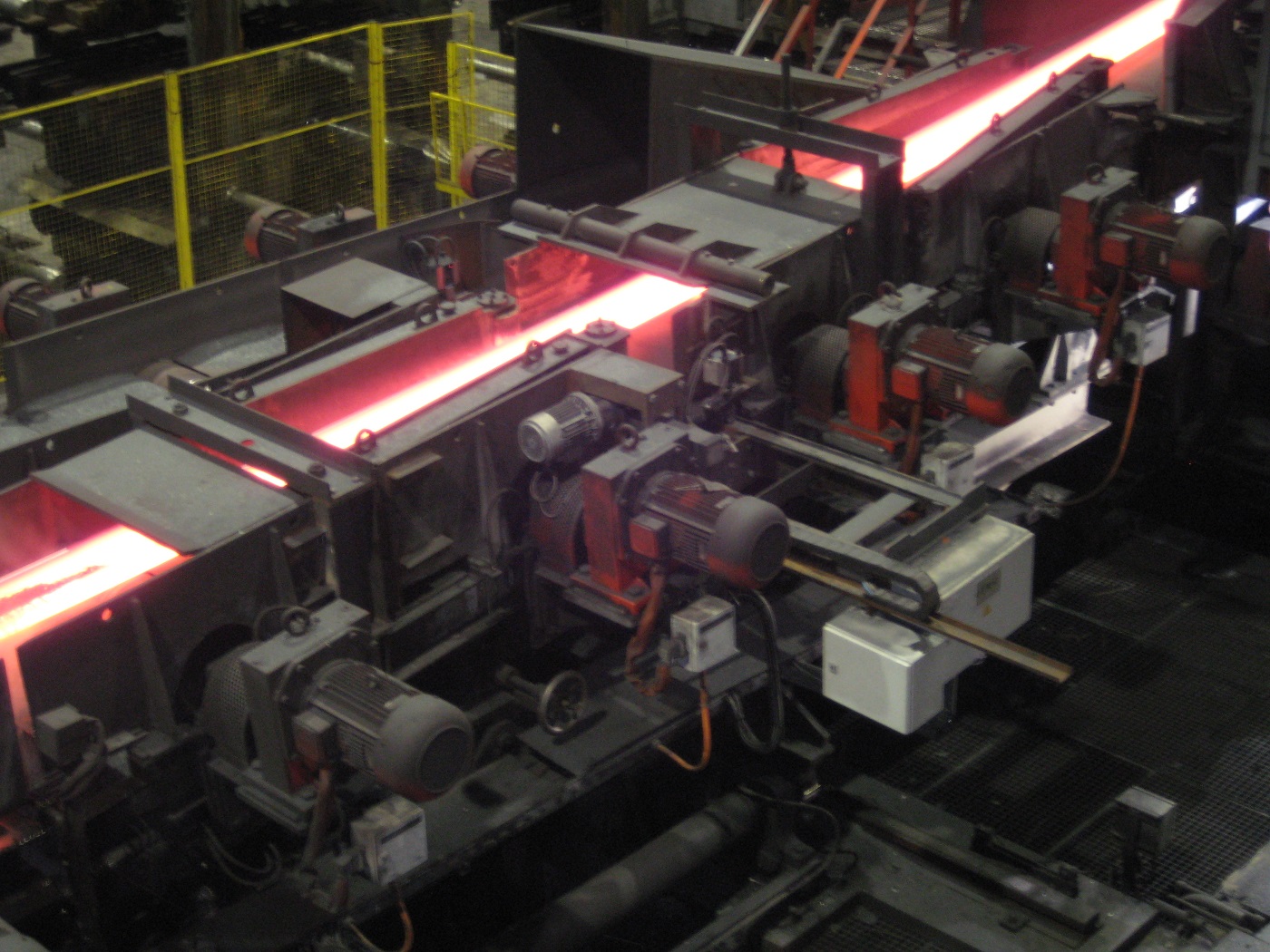

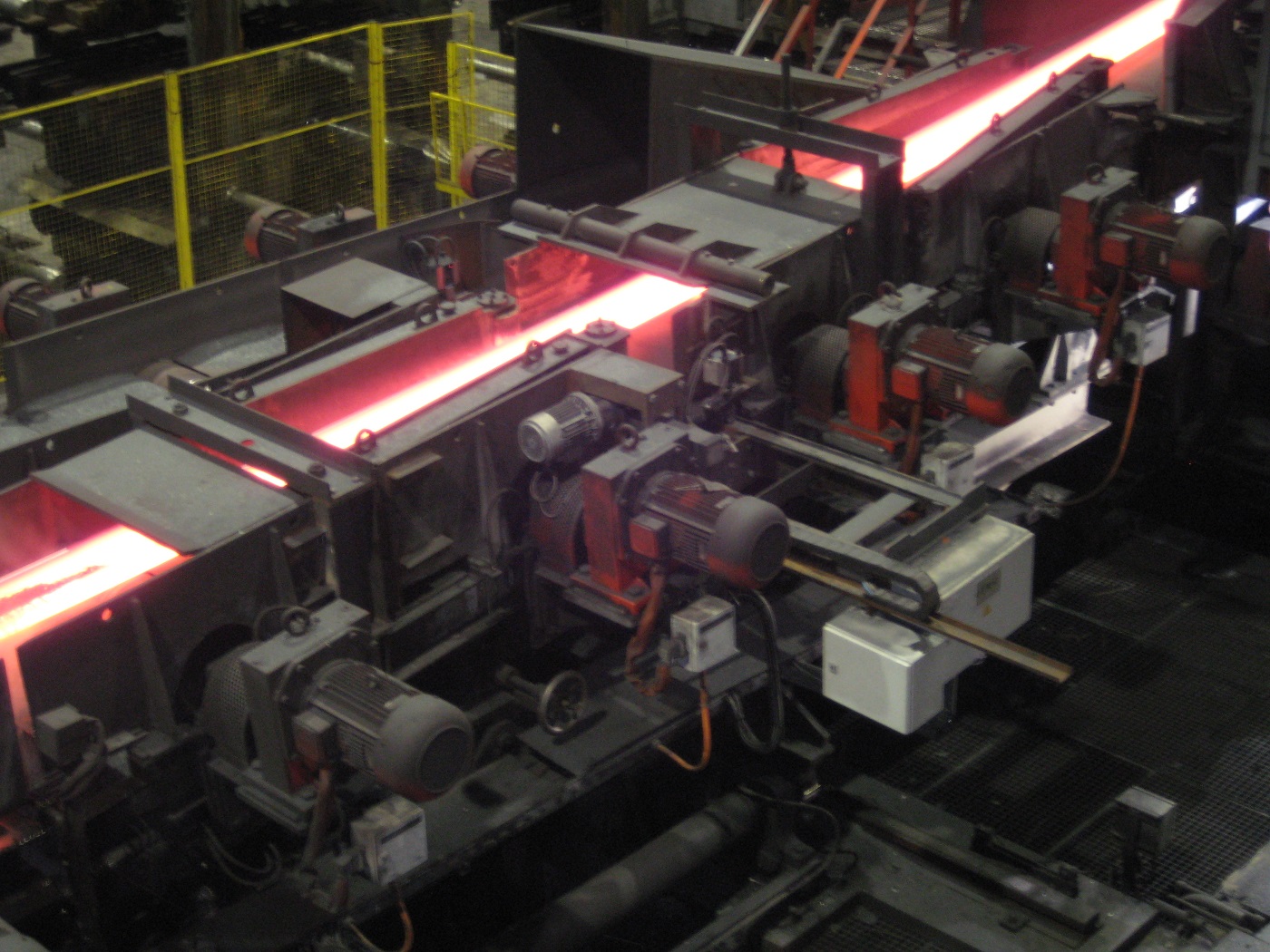

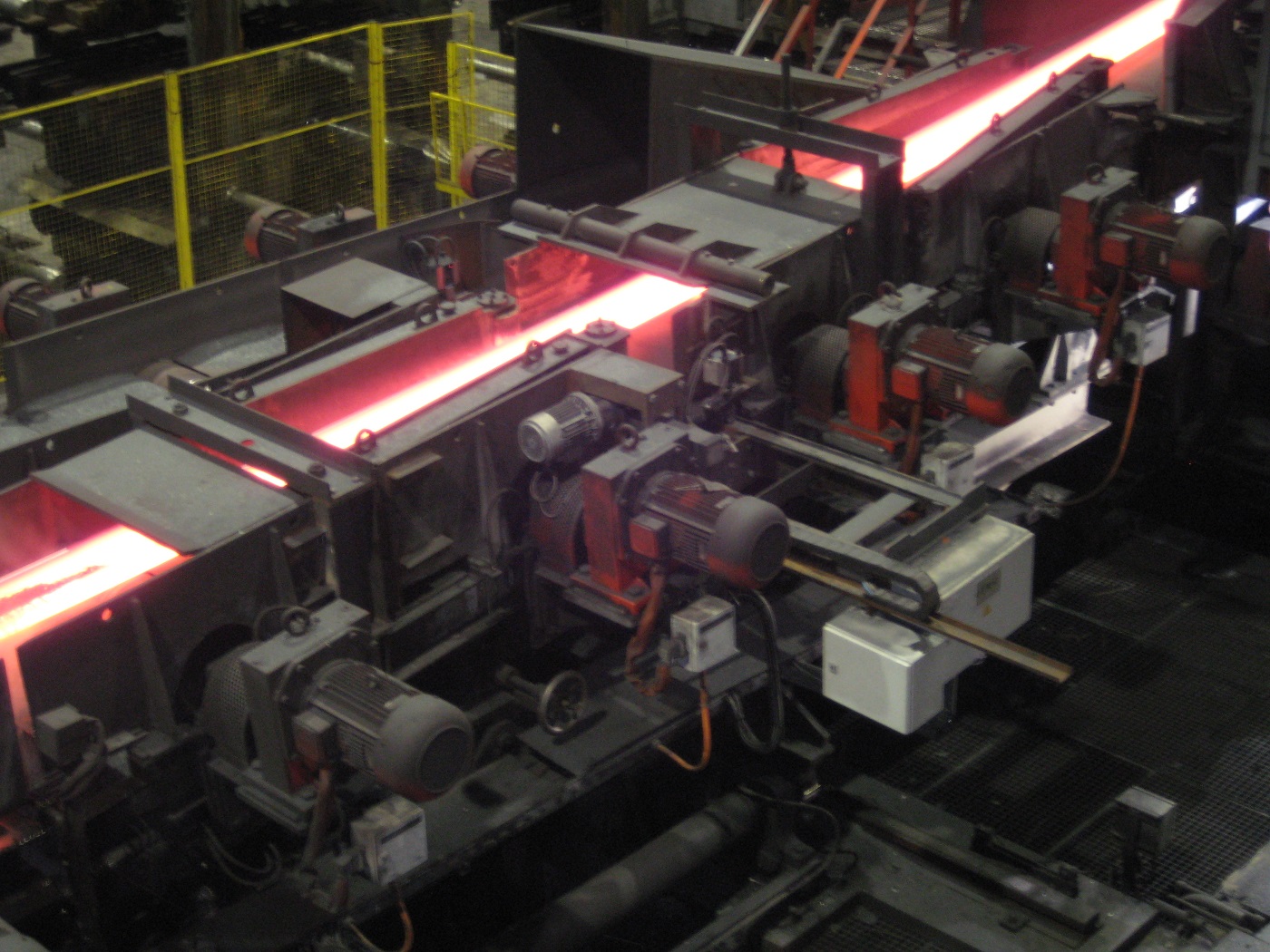

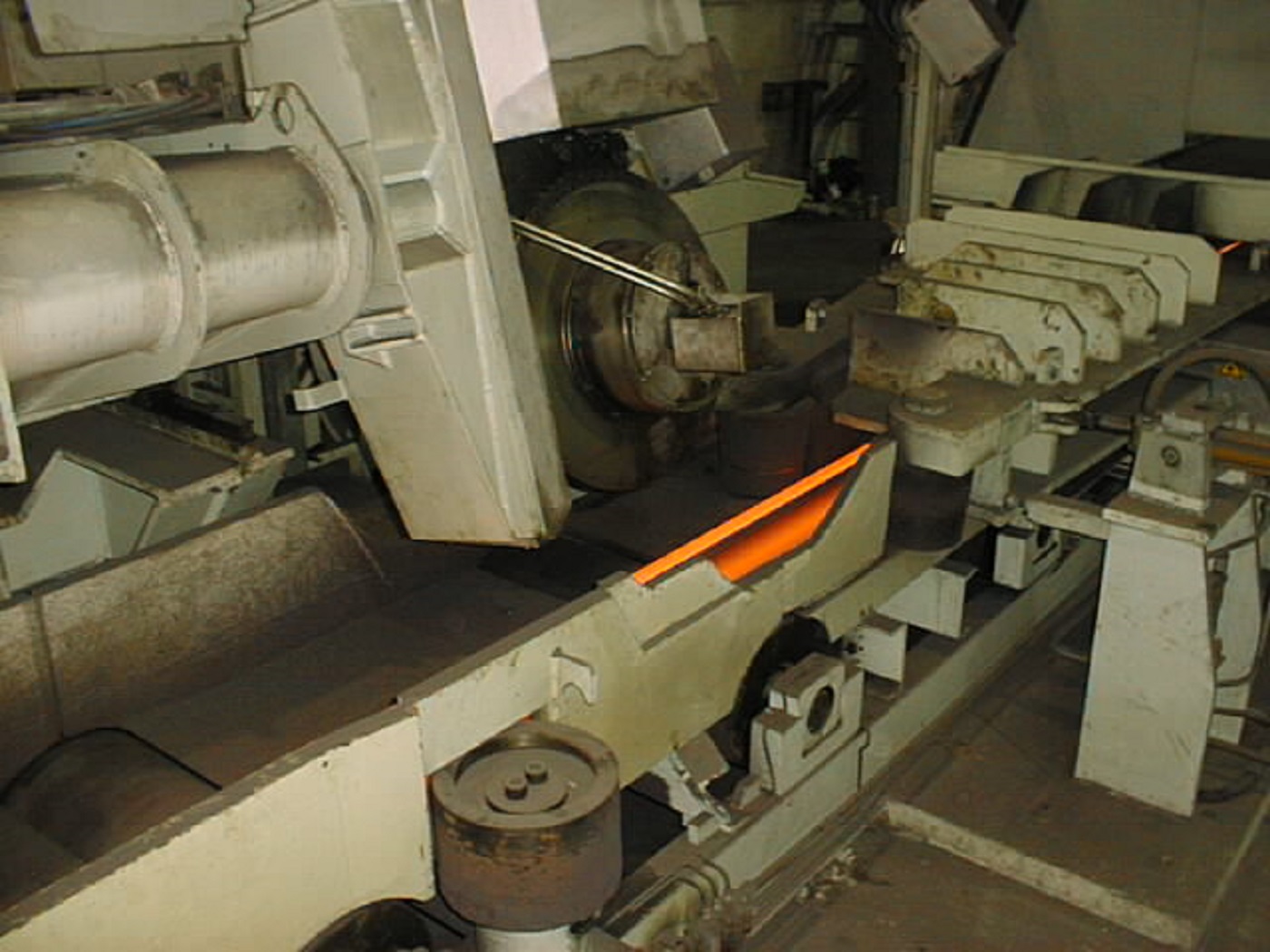

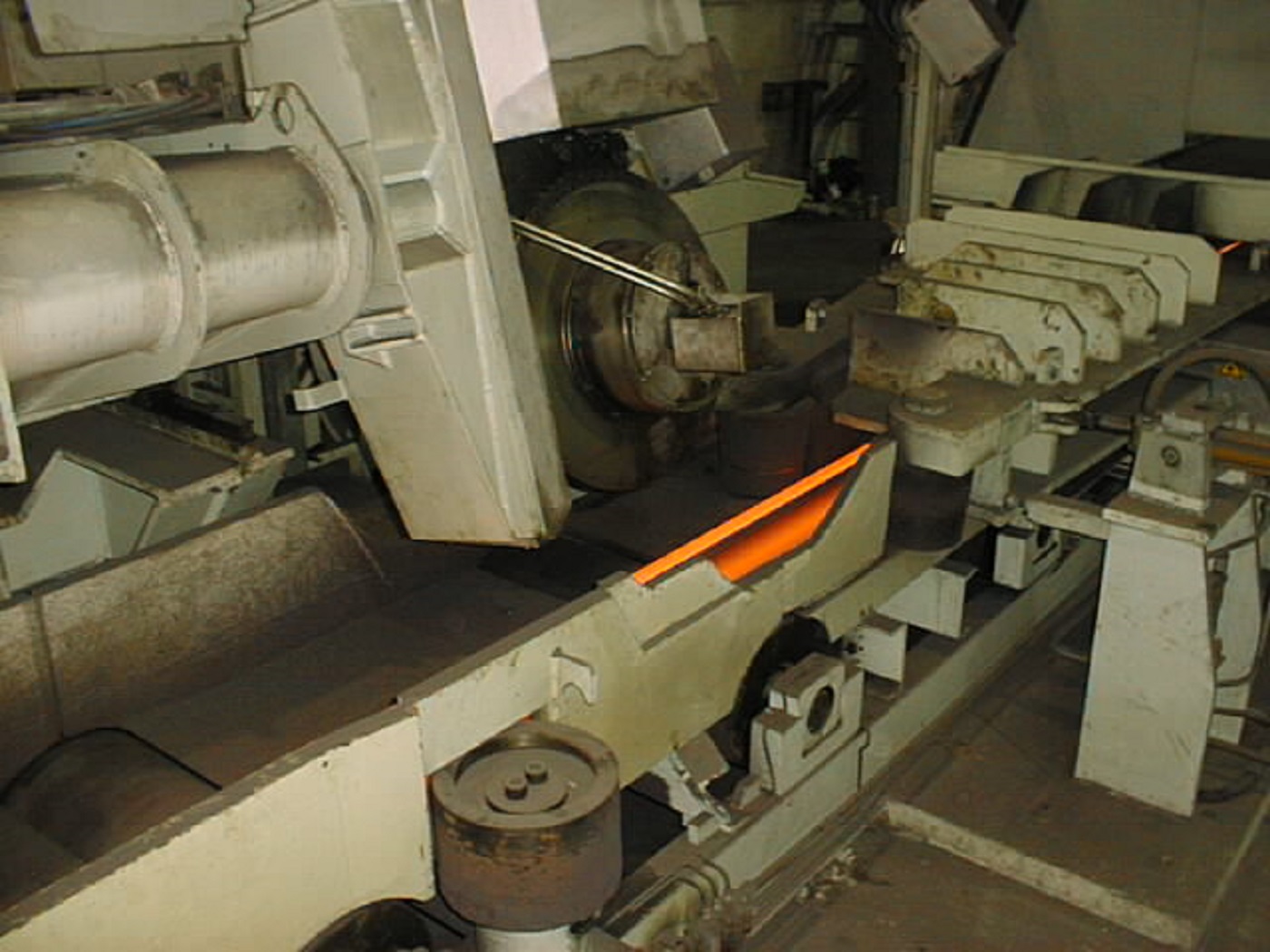

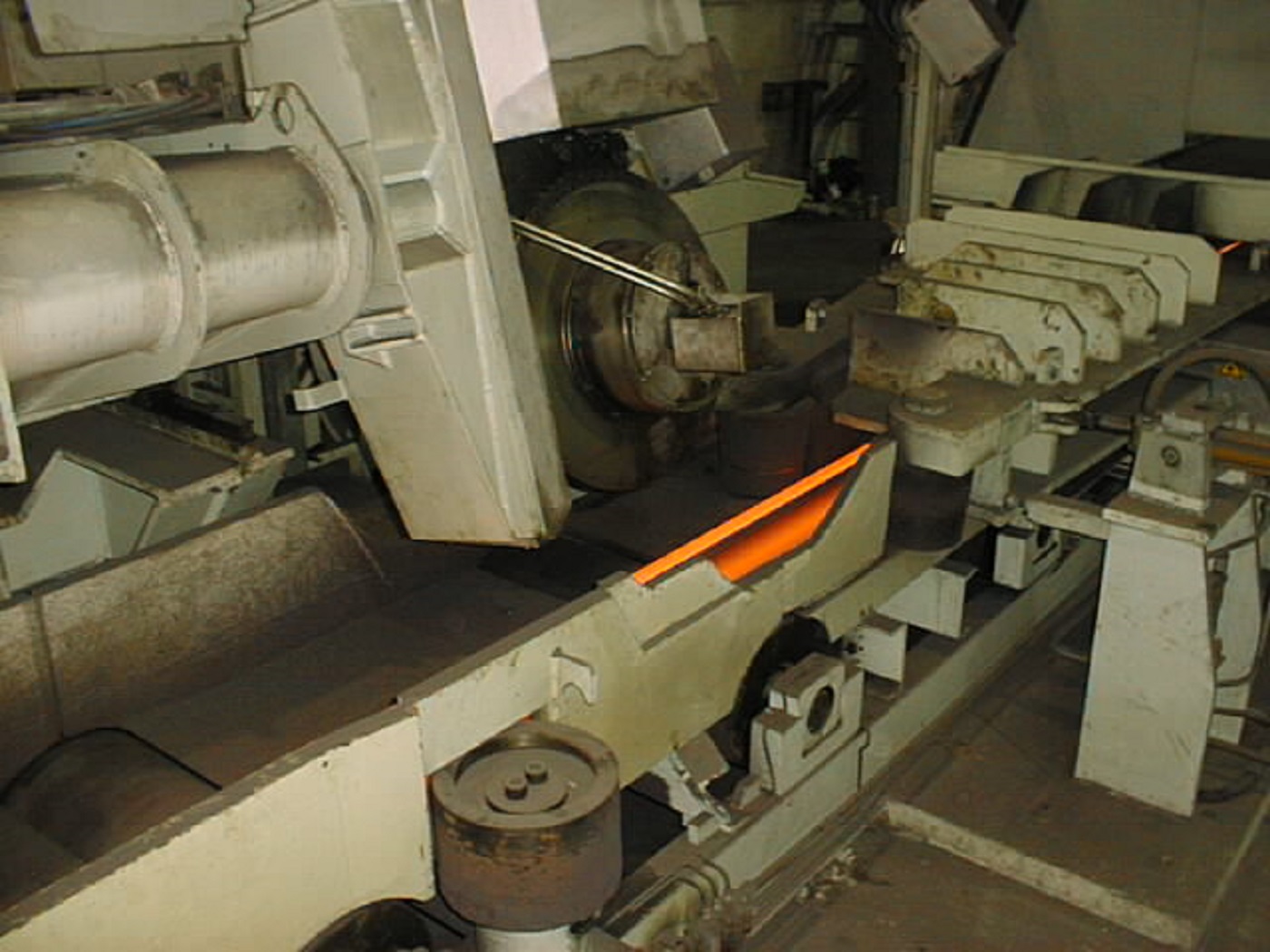

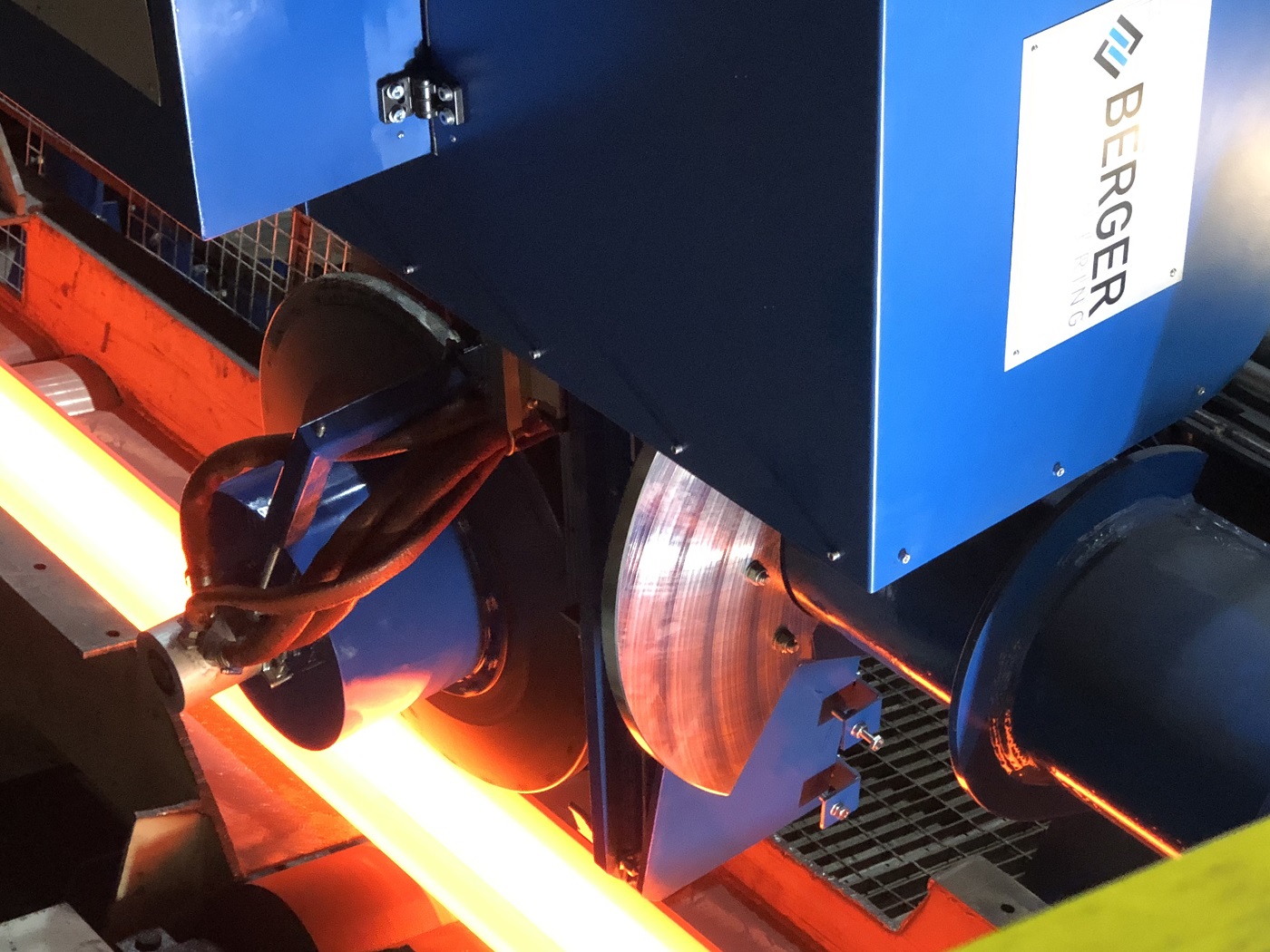

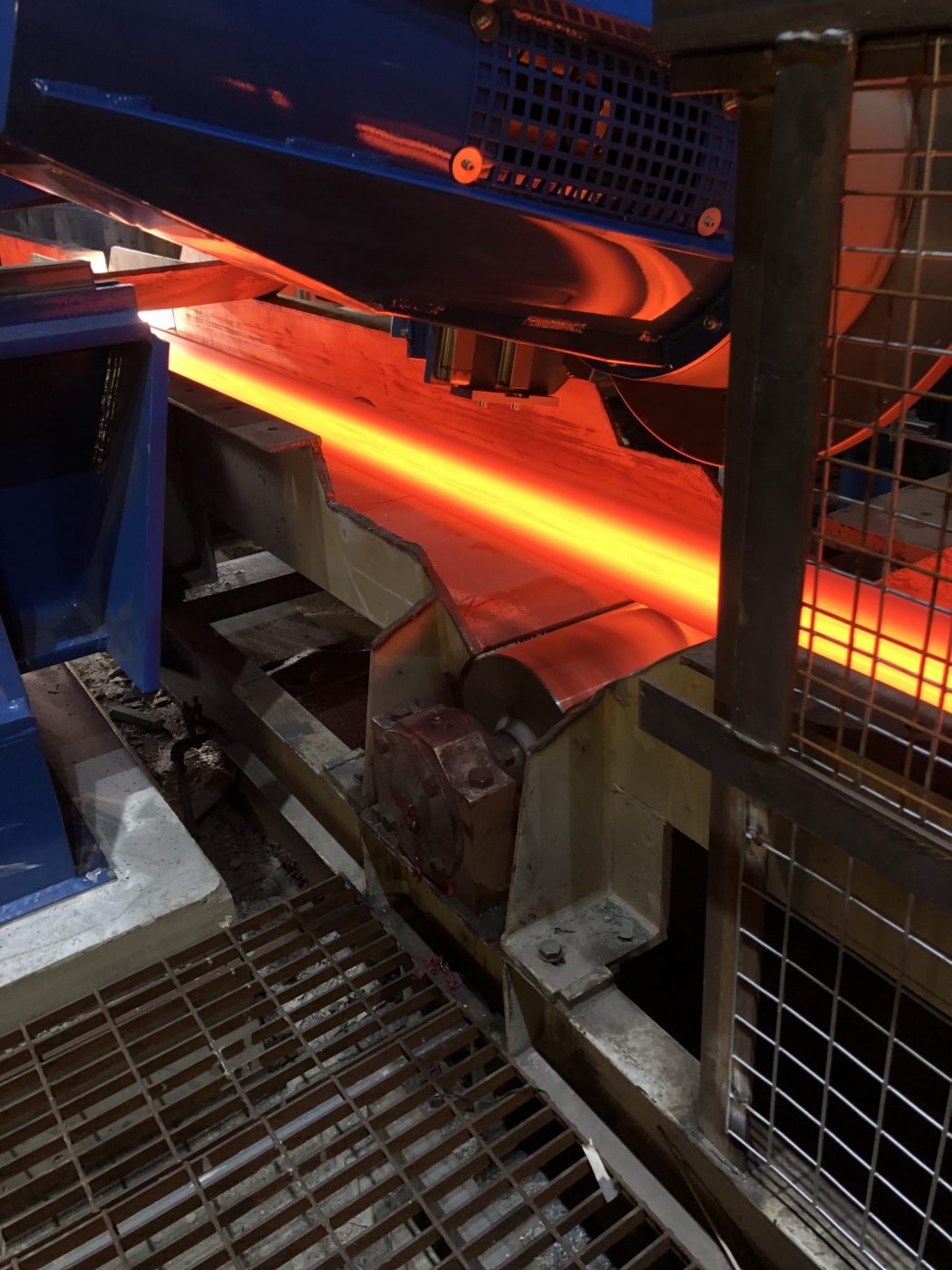

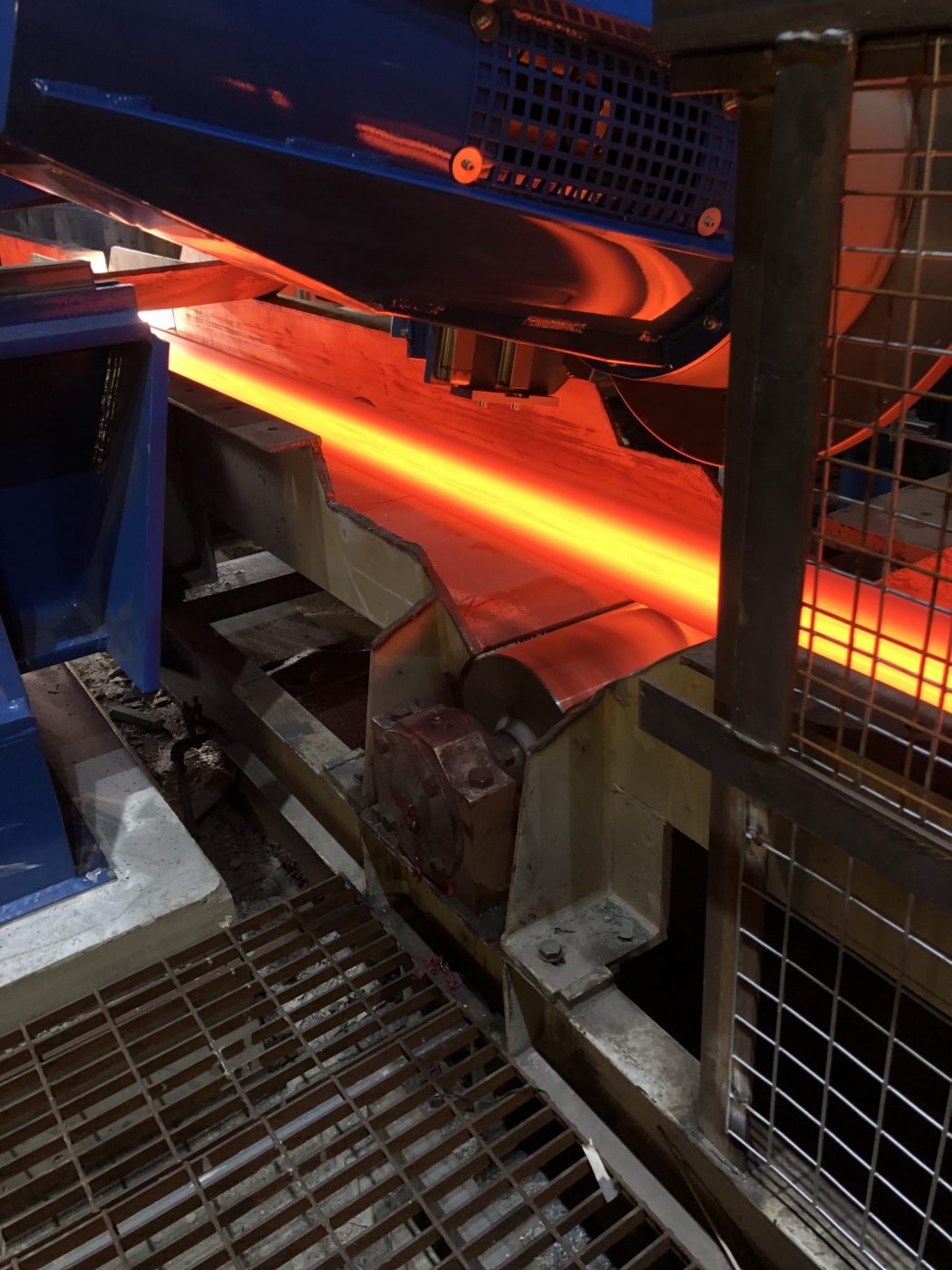

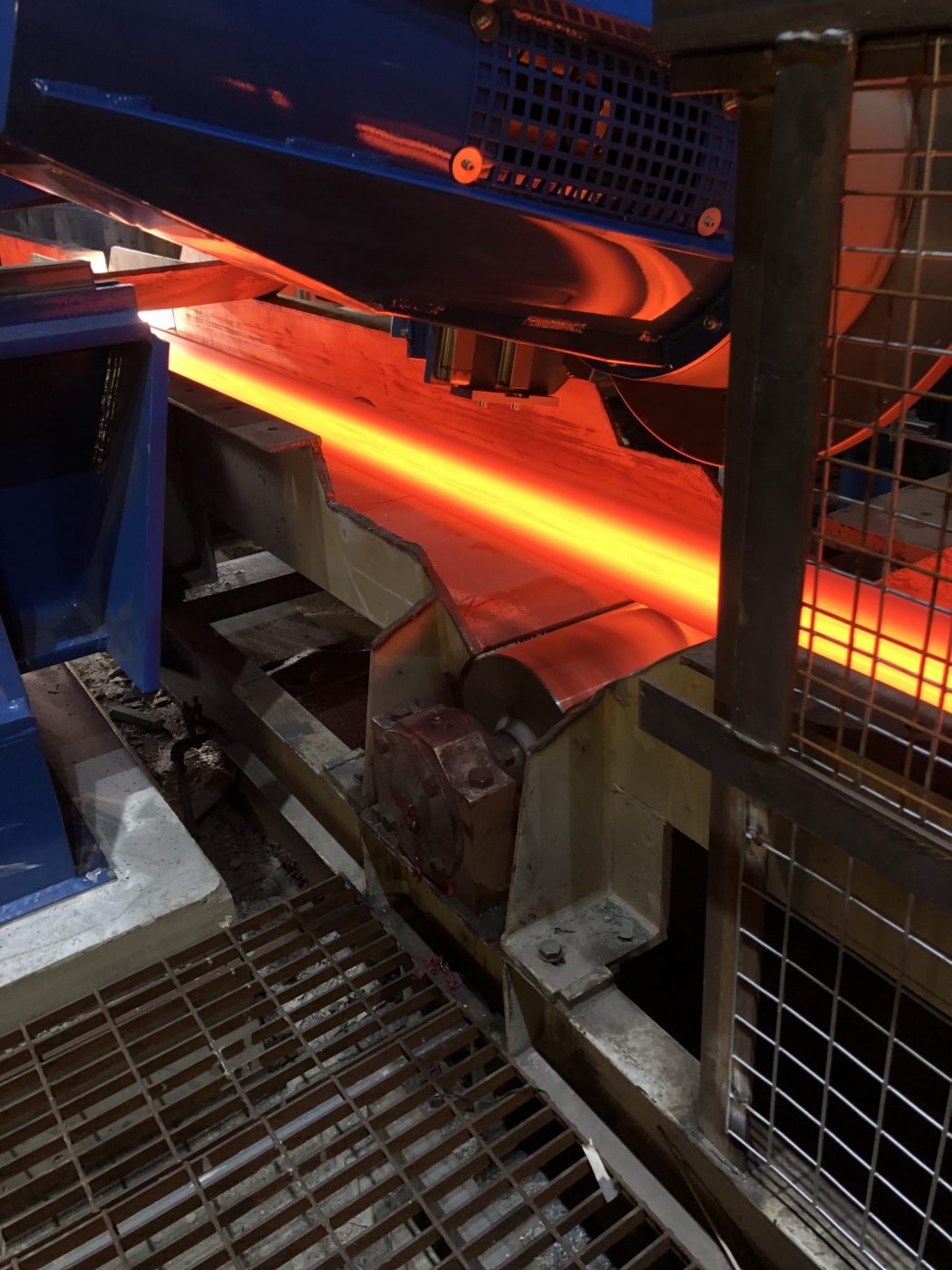

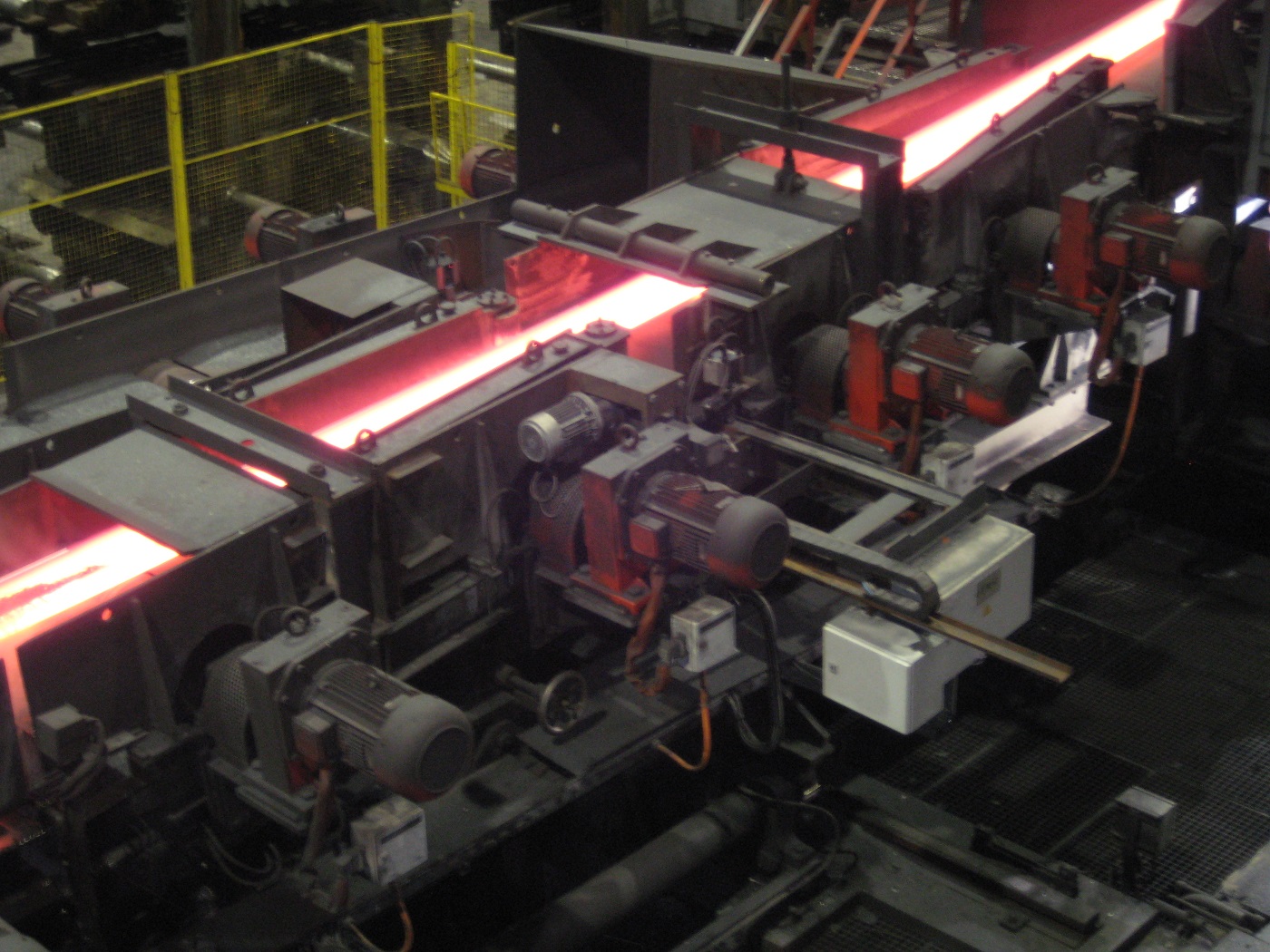

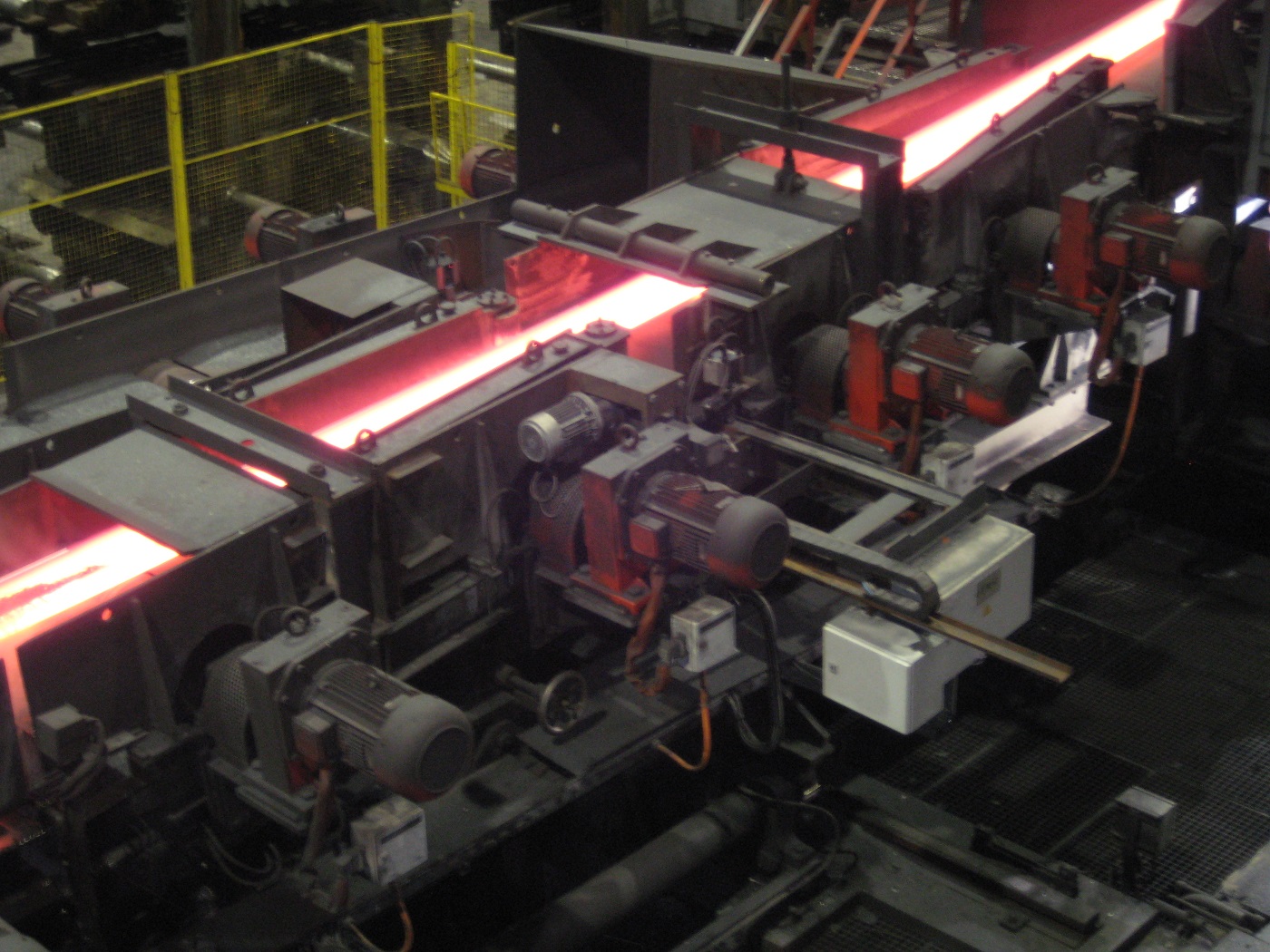

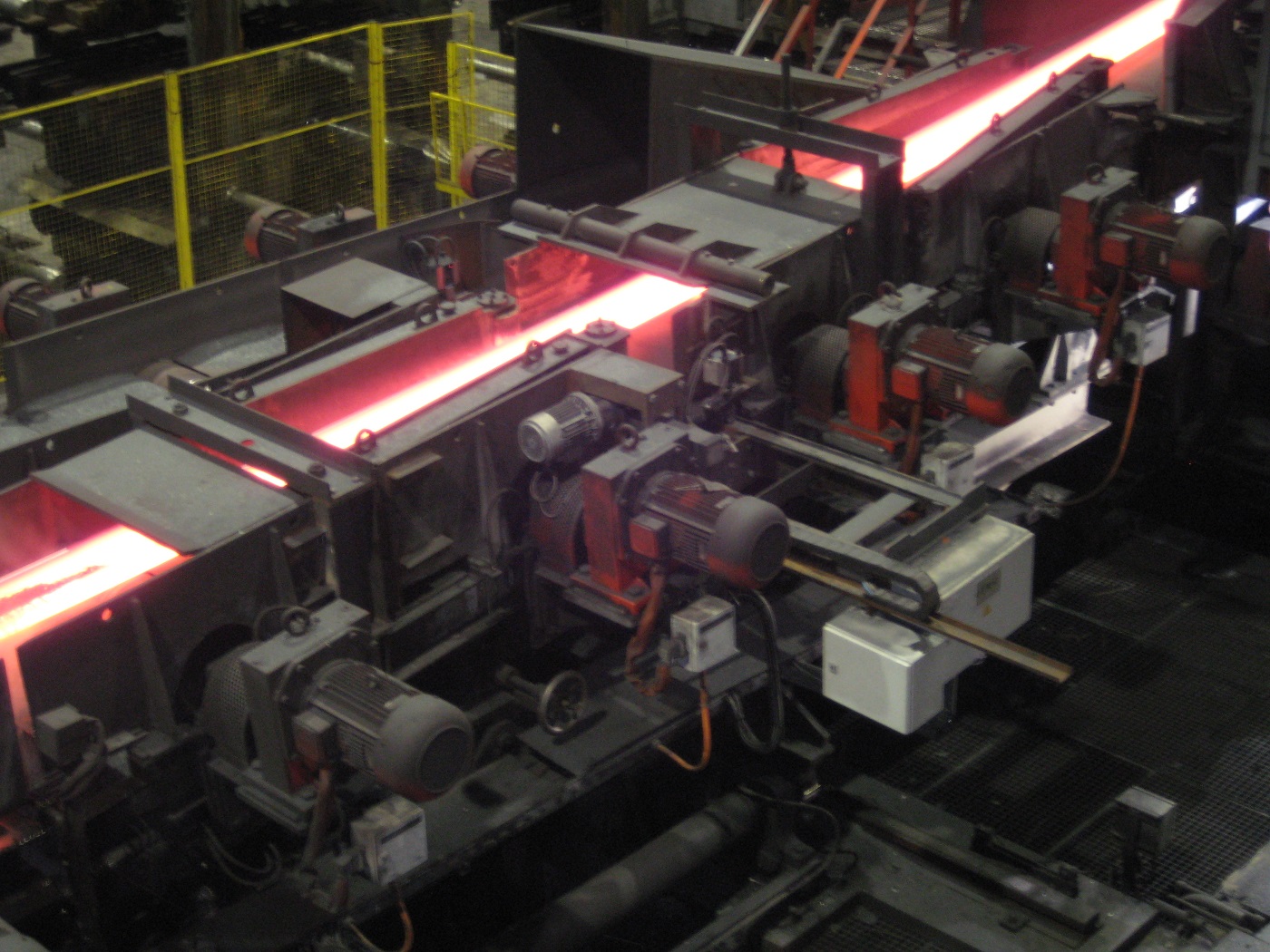

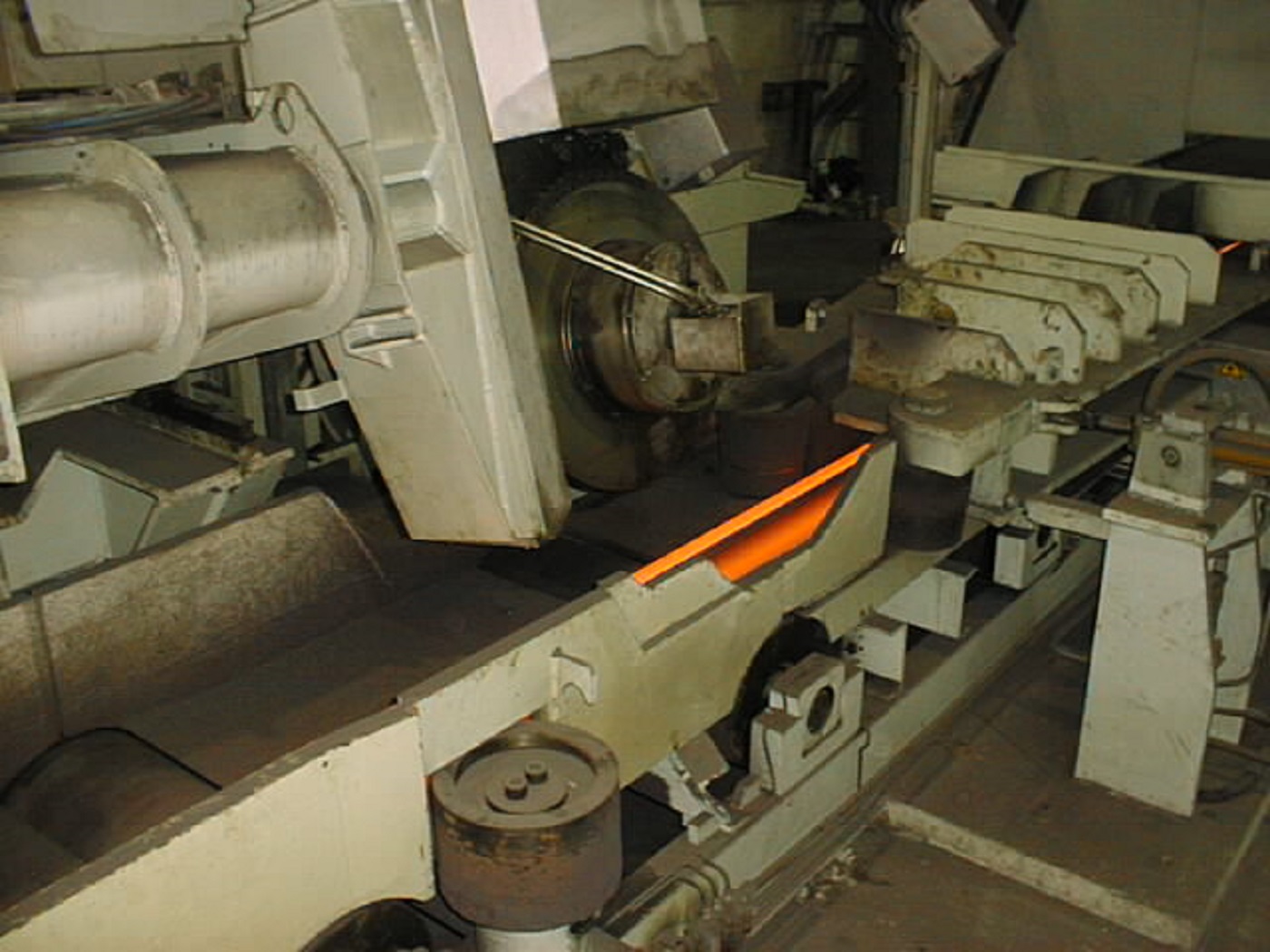

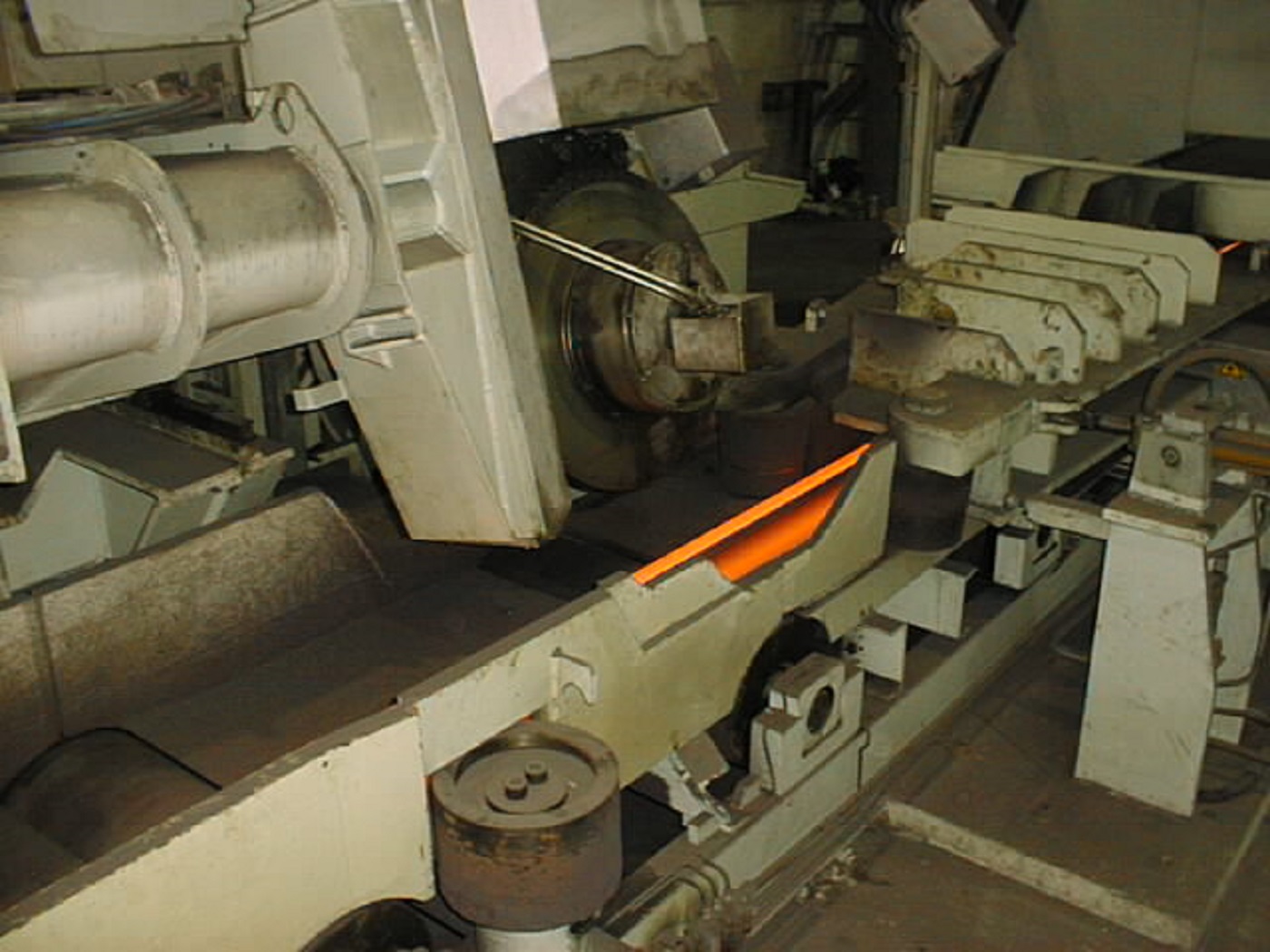

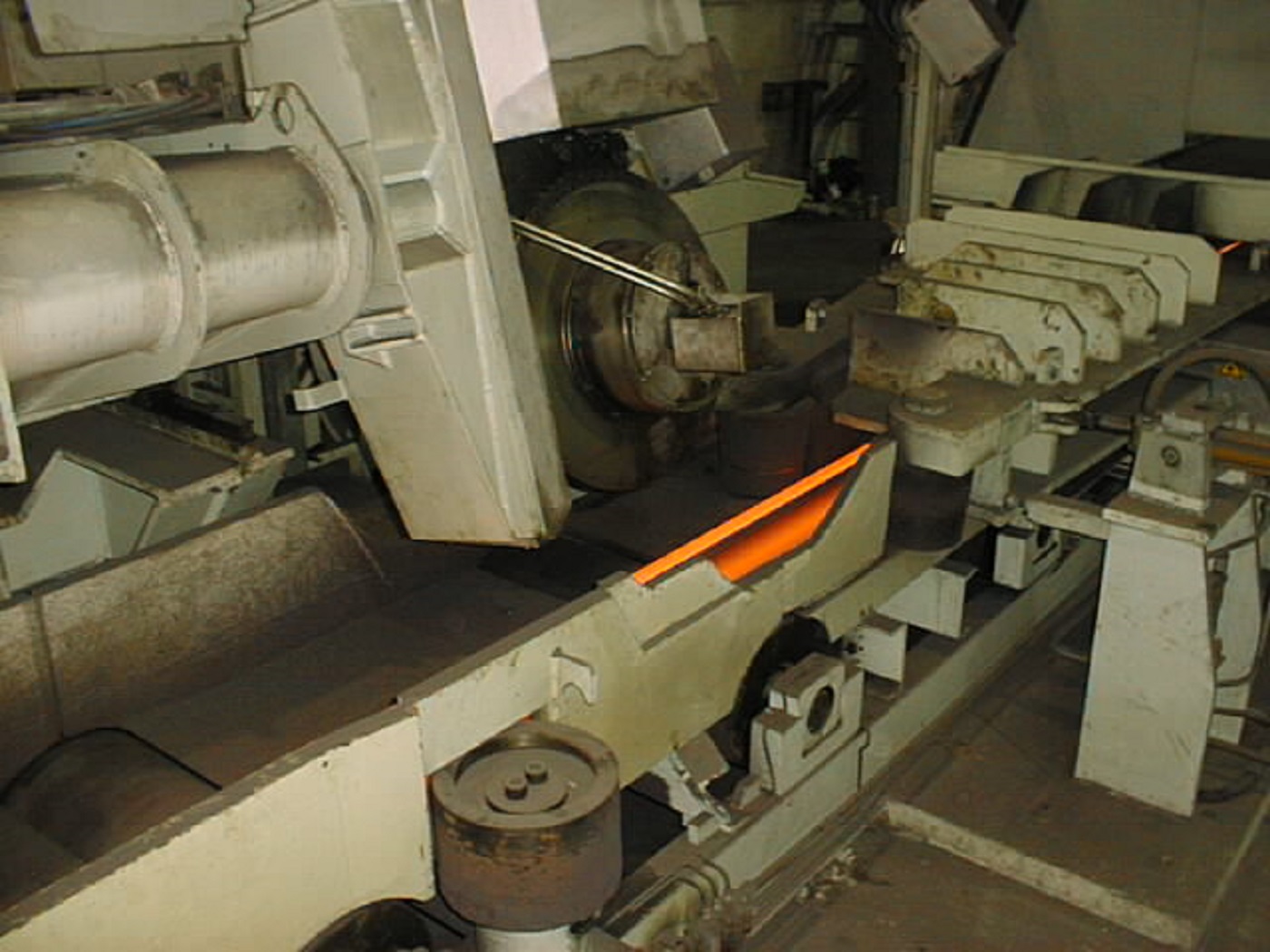

- Temp. of the rail: up to 1200°C

- Rail speed: max. 6 m/s (8 m/s Serie xPro)

- Number of characters: max. 25

- Standard size: JU….JU10, JU15, JU20

- Standard size: xPro..xPro10, xPro15, xPro20, xPro25

- Automatic rail following system

- Automatic character changing system

- Host connection for automatic data transfer

- Best technology

- Highest development status

- Inventor for rail stamping machine

Types

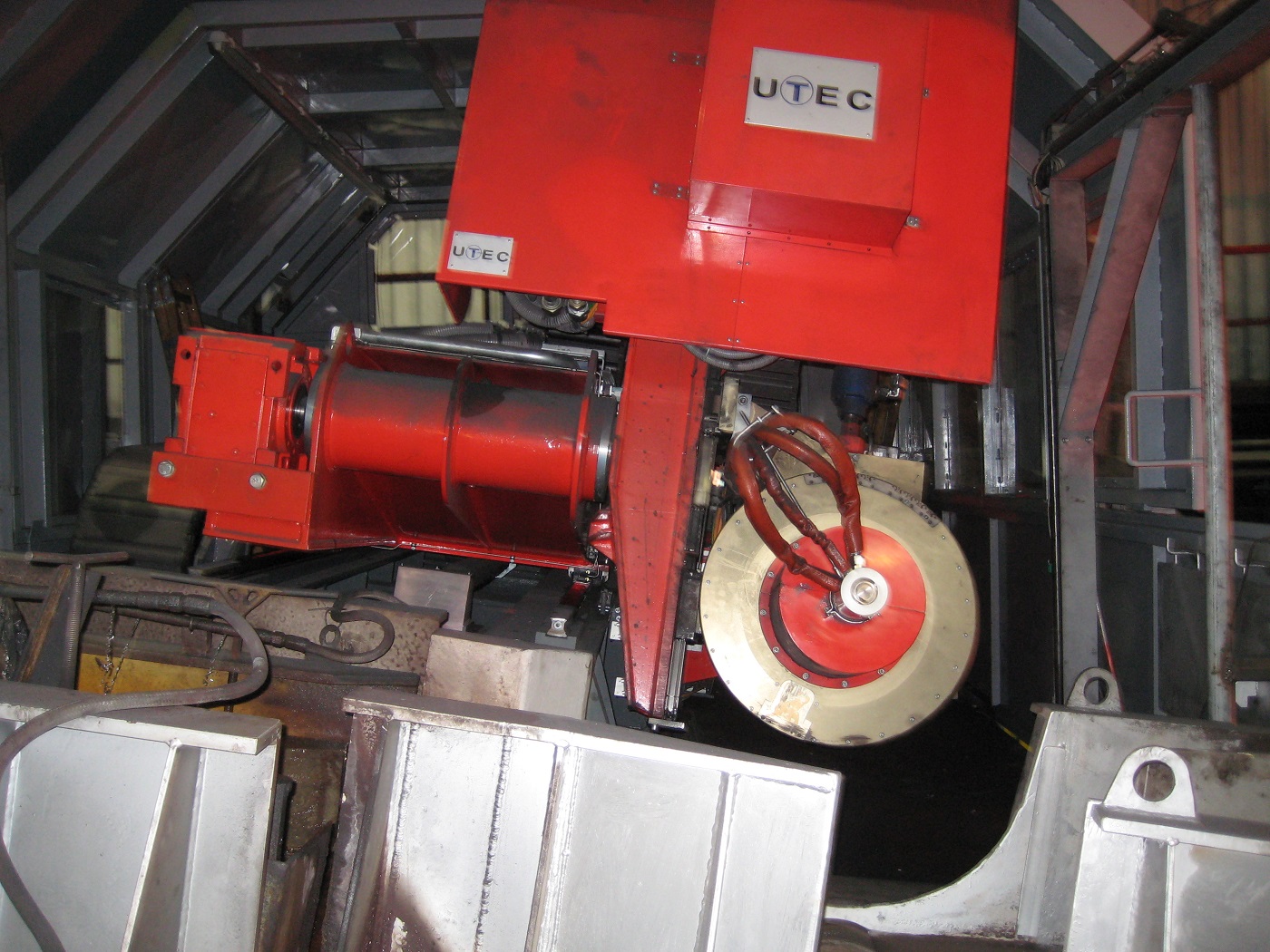

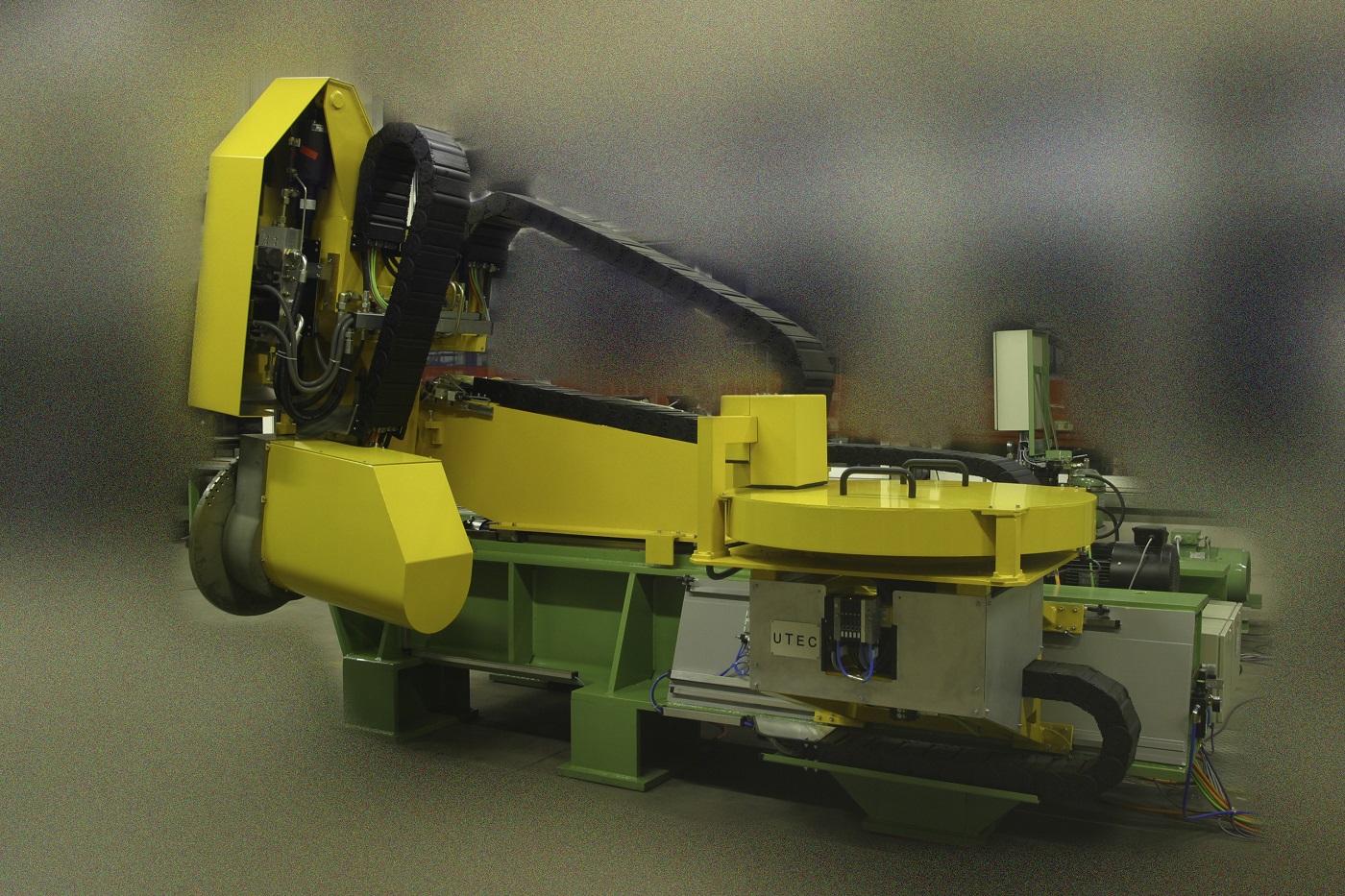

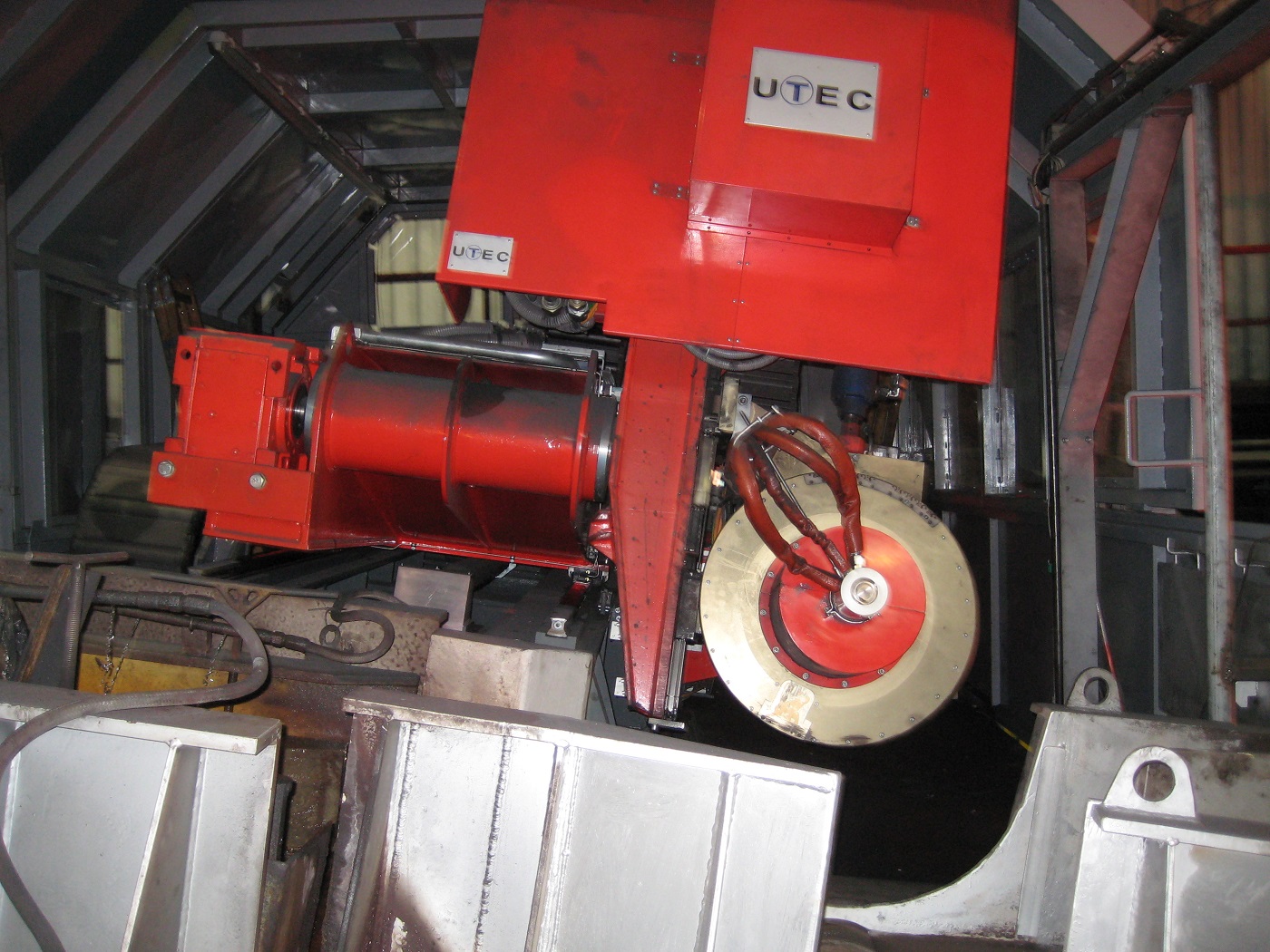

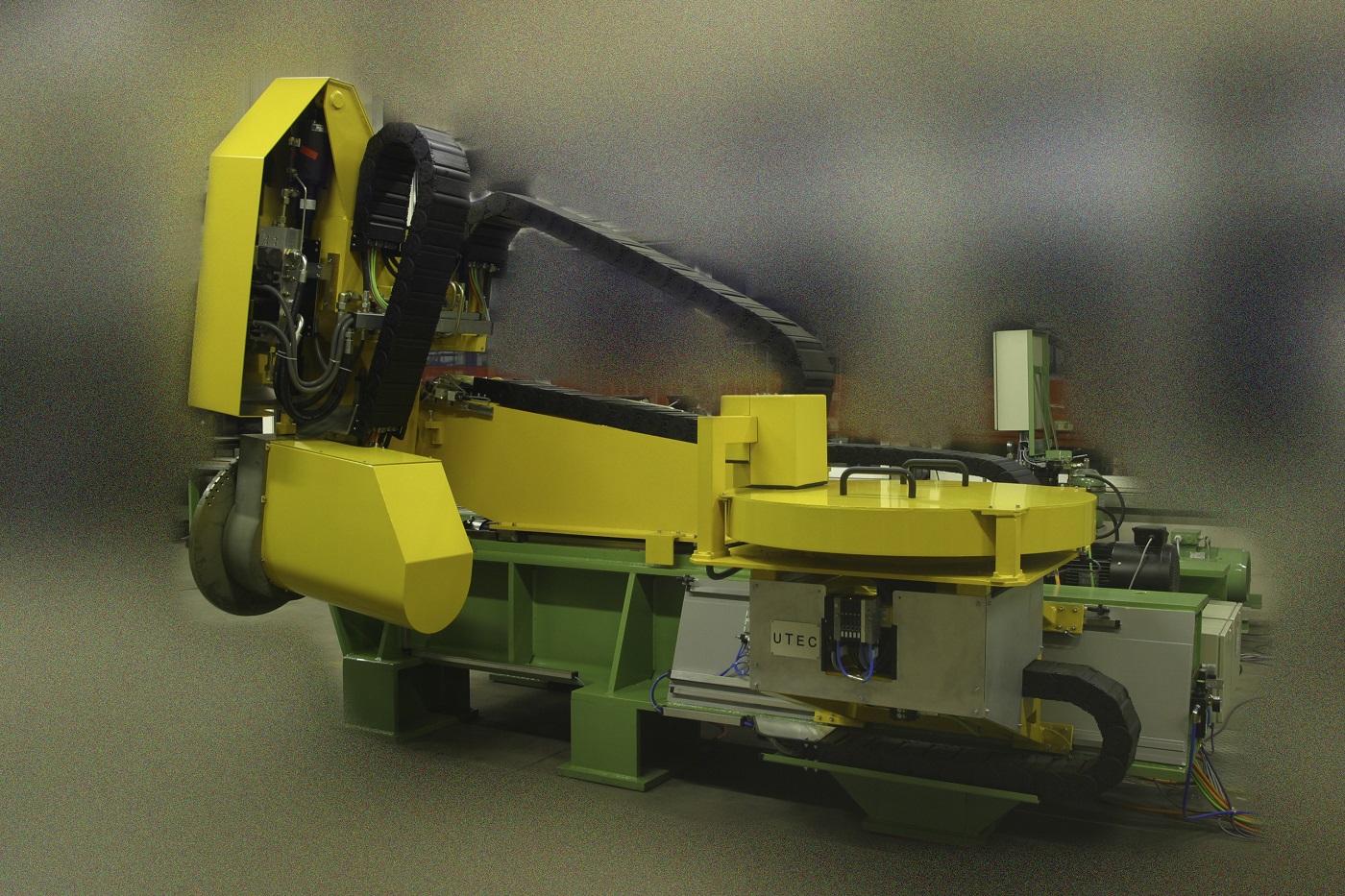

Serie JU

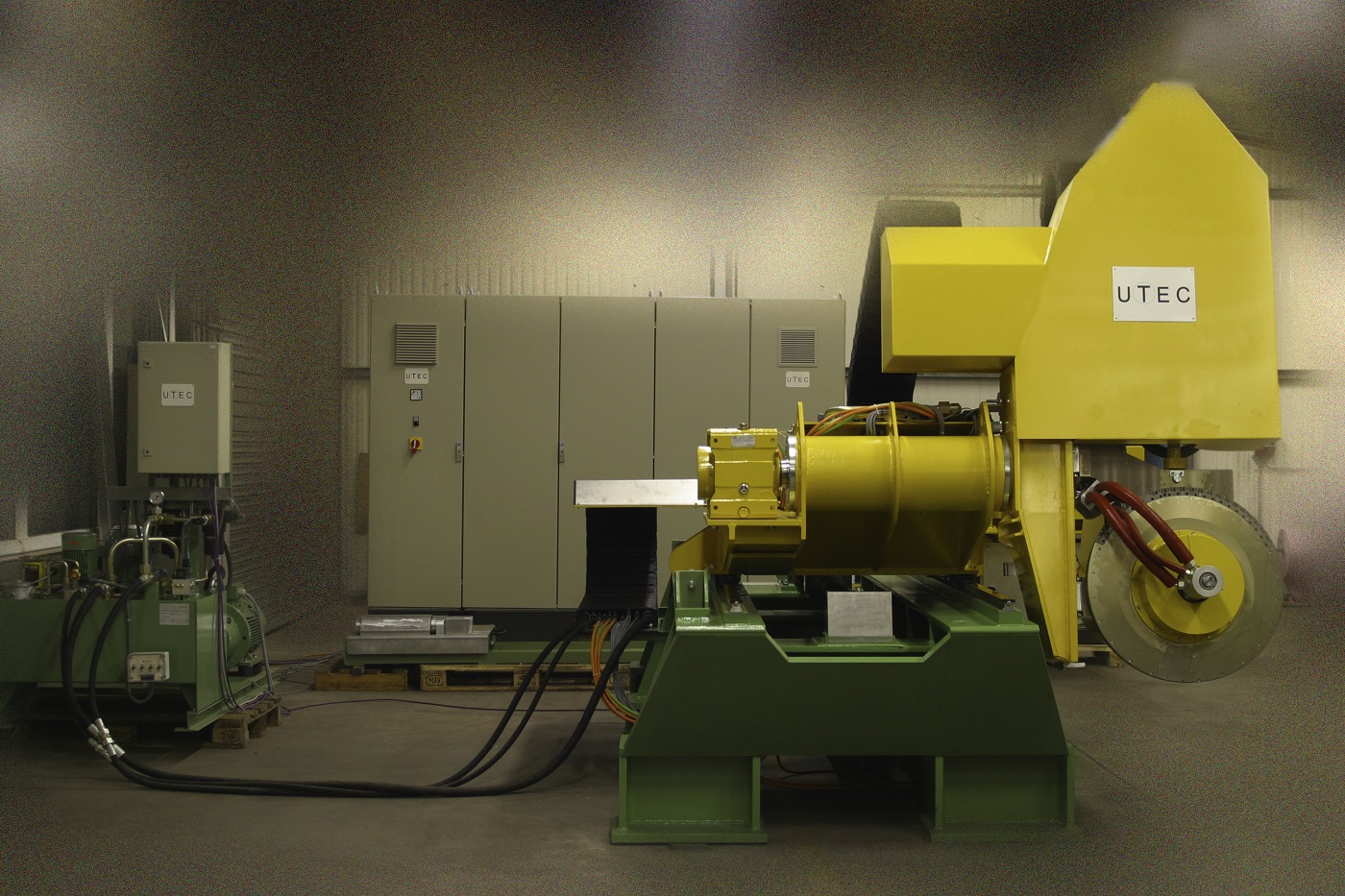

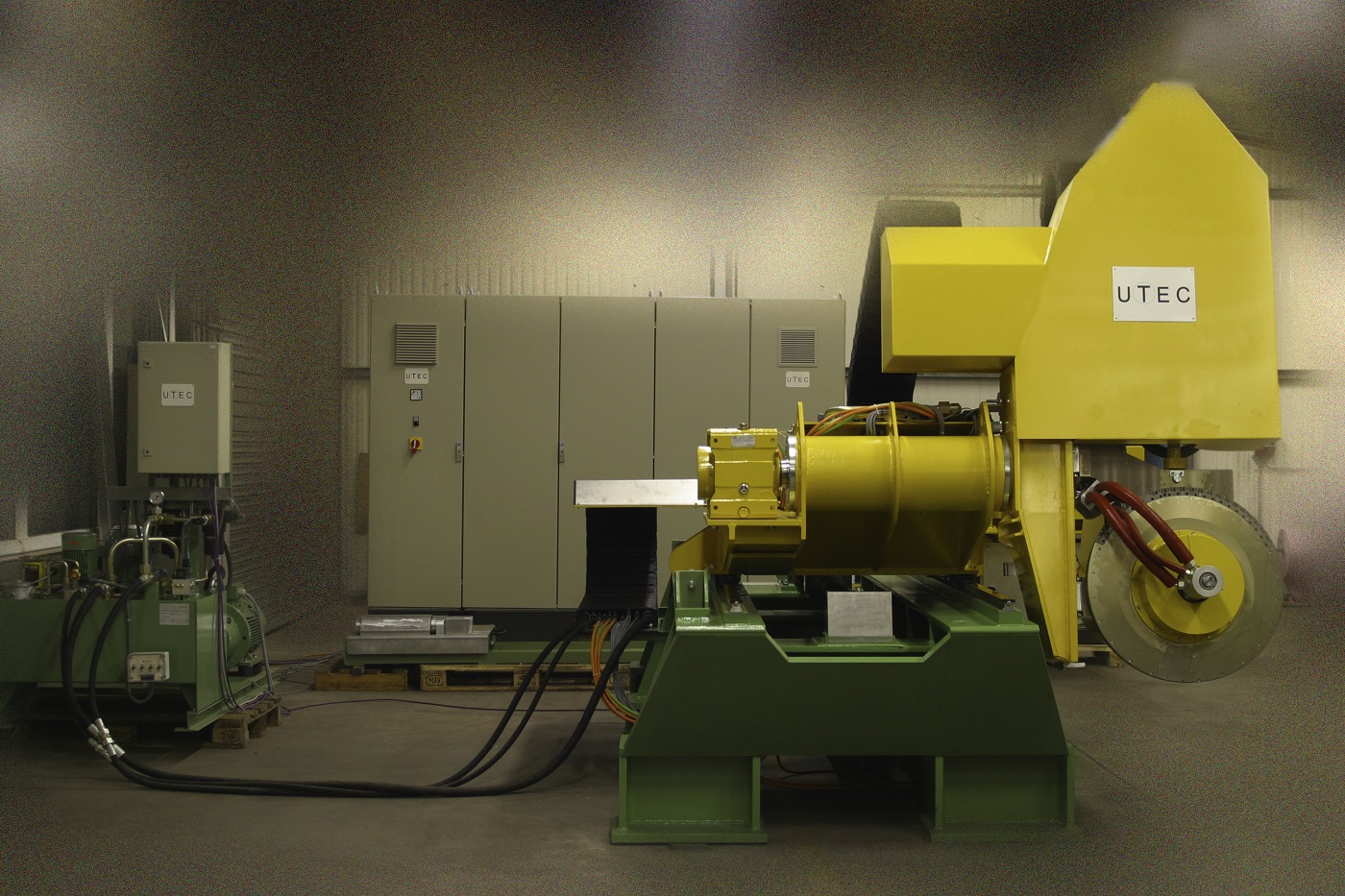

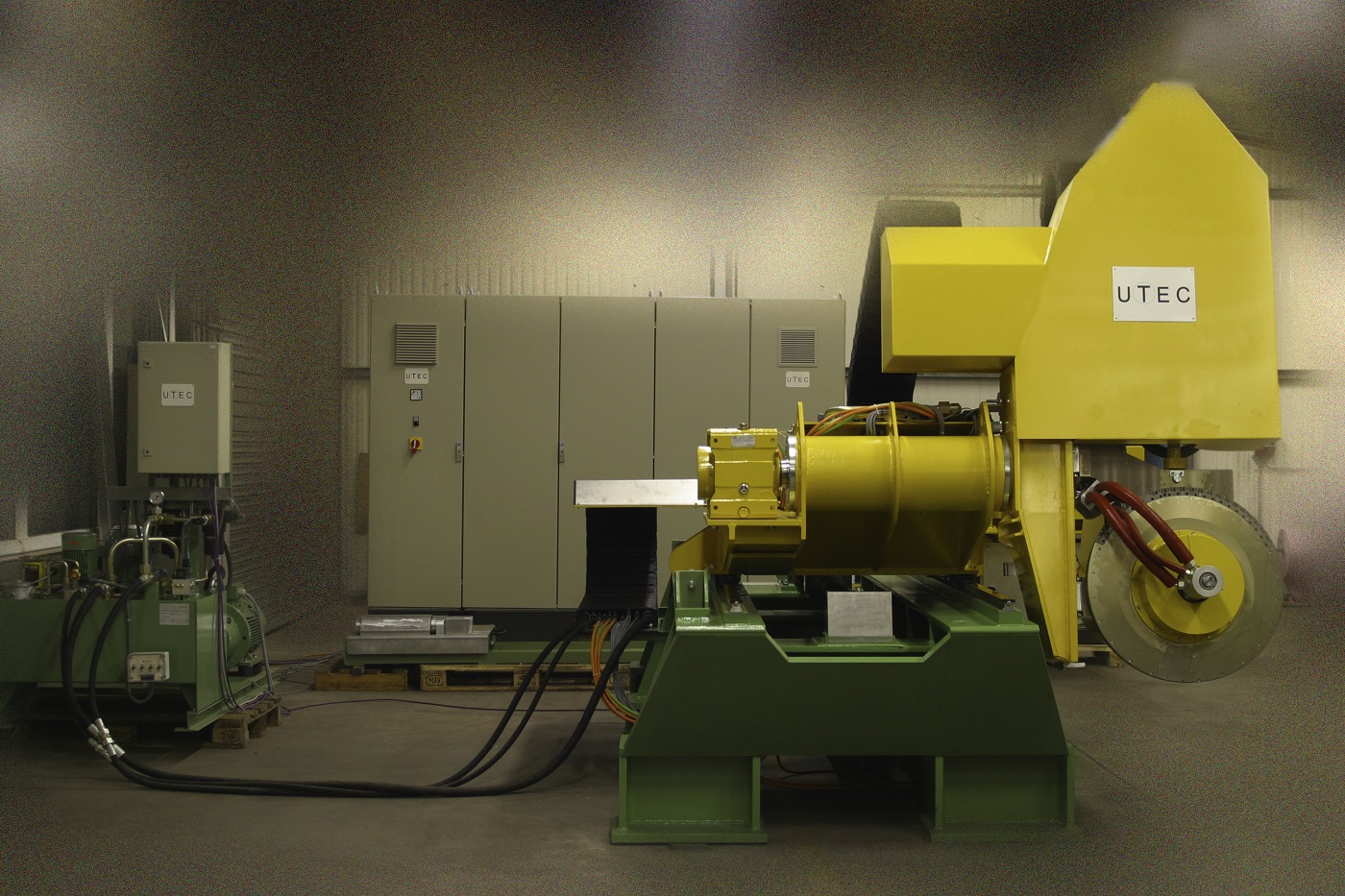

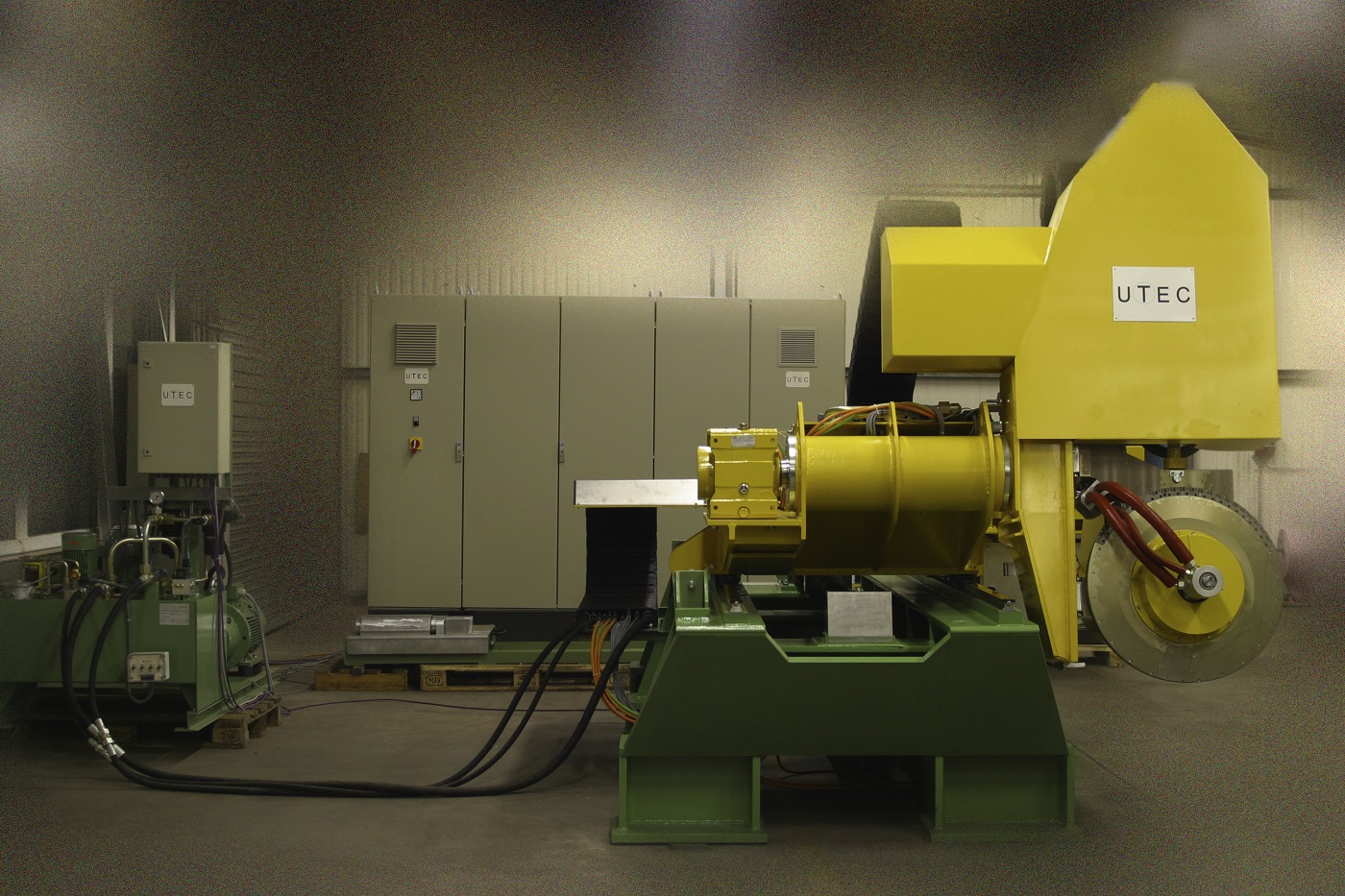

Serie xPro

Technical Specification

- Rail temp.: 790 – 1200°C (below 780°C capillary cracks are possible)

- Rail speed: max 5.0 m/s (changing 1 character); max 6.0 m/s (without changing the characters)

- 25 stamping characters (symbols) in one line – increasing possible

- Changing all characters = 60 sec

- Changing 1 character = 0.80 sec

- First stamping = 1.5 – 2.5 m

- Minimum distance between 2 stamps = 4.50 m (dependent on the rail speed)

You can find pictures and projects on our desktop view.

News about the projects

REQUEST A BROCHURE

For more information about this product, please contact us personally or request our product brochure.